loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

شوبات . 03, 2025 04:25

Back to list

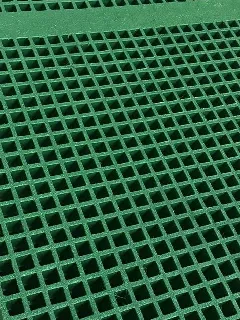

Smaller Open Mesh Area FRP Mini Mesh Grating

In the industrial world, GRP (Glass Reinforced Plastic) gratings are increasingly becoming the cornerstone for numerous applications, prized for their durability, versatility, and lightweight nature. Professionals in industries ranging from chemical processing to offshore energy are looking for reliable GRP grating specifications that ensure safety, efficiency, and cost-effectiveness. Understanding these specifications is critical for making informed decisions that bolster facility operations and worker safety.

Slip resistance is another specification that cannot be overlooked, particularly in industries where safety is paramount. GRP gratings typically feature a grit-top surface to enhance traction, significantly reducing the chance of slips and falls. This is particularly valuable in wet or oily conditions, where slips could lead to serious workplace injuries. Of course, the installation environment plays a role in specification decisions. For outdoor installations, UV stabilized GRP gratings are available to combat the effects of long-term sun exposure, which can lead to material degradation and discolouration. Ensuring that the grating is designed with UV stabilization will prolong durability and maintain the appearance of the grating over time. From an expertise and reliability standpoint, partnering with a reputable supplier is paramount. Suppliers with a strong track record offer insights into customization options that might benefit specific applications, such as unique mesh sizes or panel shapes. They also provide supportive documentation that guarantees compliance with international standards, which serves as a mark of trustworthiness and assures the structural quality of the GRP gratings. Certification and third-party testing add another layer of trustworthiness to your GRP grating selection, offering peace of mind that the product meets stringent safety and quality benchmarks. Independent testing verifies properties such as load capacity, chemical resistance, and slip resistance, enabling industry professionals to rely on these products in critical applications. Understanding GRP grating specifications embodies the intersection of experience, expertise, authority, and trust. These products' adaptability and robustness make them invaluable resources for sustaining infrastructure integrity across various sectors. Choosing the correct specifications tailored to specific industrial needs ensures the longevity and safety of your investments, safeguarding both workers and operational efficiency.

Slip resistance is another specification that cannot be overlooked, particularly in industries where safety is paramount. GRP gratings typically feature a grit-top surface to enhance traction, significantly reducing the chance of slips and falls. This is particularly valuable in wet or oily conditions, where slips could lead to serious workplace injuries. Of course, the installation environment plays a role in specification decisions. For outdoor installations, UV stabilized GRP gratings are available to combat the effects of long-term sun exposure, which can lead to material degradation and discolouration. Ensuring that the grating is designed with UV stabilization will prolong durability and maintain the appearance of the grating over time. From an expertise and reliability standpoint, partnering with a reputable supplier is paramount. Suppliers with a strong track record offer insights into customization options that might benefit specific applications, such as unique mesh sizes or panel shapes. They also provide supportive documentation that guarantees compliance with international standards, which serves as a mark of trustworthiness and assures the structural quality of the GRP gratings. Certification and third-party testing add another layer of trustworthiness to your GRP grating selection, offering peace of mind that the product meets stringent safety and quality benchmarks. Independent testing verifies properties such as load capacity, chemical resistance, and slip resistance, enabling industry professionals to rely on these products in critical applications. Understanding GRP grating specifications embodies the intersection of experience, expertise, authority, and trust. These products' adaptability and robustness make them invaluable resources for sustaining infrastructure integrity across various sectors. Choosing the correct specifications tailored to specific industrial needs ensures the longevity and safety of your investments, safeguarding both workers and operational efficiency.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025