loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

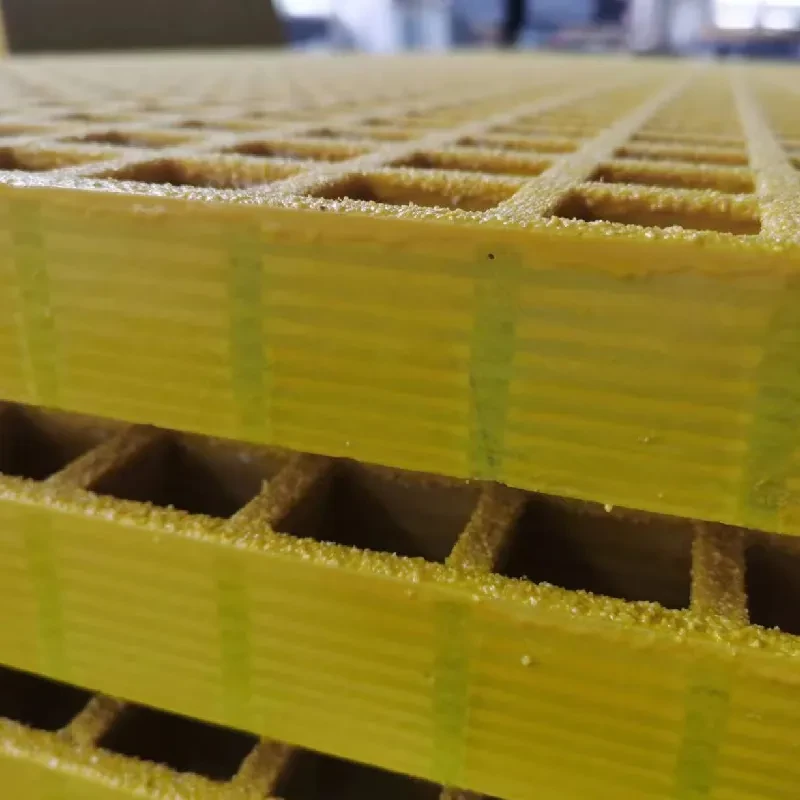

Innovative Applications of FRP Grating Sheets in Modern Construction and Design

Understanding FRP Grating Sheets A Comprehensive Overview

Fiber Reinforced Plastic (FRP) grating sheets have become a vital component in various industrial and commercial applications. Made from a composite material, FRP grating is designed to offer strength, durability, and resistance to harsh environmental conditions. This article delves into the properties, benefits, applications, and installation of FRP grating sheets.

What is FRP Grating?

FRP grating is produced using a combination of glass fibers and resin, which are layered and cured to form a rigid and lightweight structure. The process typically involves the use of a pultrusion method, where fibers are pulled through a resin bath and then formed into a desired shape. The resulting grating sheets consist of a grid-like pattern, which enhances their strength while allowing light, air, and water to pass through.

Key Properties of FRP Grating Sheets

One of the most notable characteristics of FRP grating sheets is their exceptional corrosion resistance. Unlike traditional materials such as steel, which can rust and degrade over time when exposed to moisture or chemicals, FRP grating is impervious to corrosion from saltwater, chemicals, and other harmful substances. This makes them ideal for use in various environments, including marine, chemical processing, and wastewater treatment facilities.

Additionally, FRP grating is lightweight yet incredibly strong. This combination of properties allows for easier handling and installation while maintaining the structural integrity required for heavy loads. The open design of the grating provides slip resistance, which enhances safety for pedestrians and equipment operating in these areas.

Advantages of FRP Grating

1. Durability FRP grating is engineered to withstand extreme weather conditions, making it suitable for outdoor applications. It can endure varying temperatures, UV exposure, and even impacts from heavy equipment.

2. Maintenance-Free The non-corrosive properties of FRP mean that it requires minimal maintenance compared to traditional materials. This not only lowers the overall cost of ownership but also ensures consistent performance over time.

frp grating sheet

3. Customizable FRP grating sheets can be manufactured in various sizes, thicknesses, and colors, allowing for customization to fit specific project requirements. They can also be designed to meet certain load-bearing standards.

4. Eco-Friendly The production of FRP materials often involves recyclable components, and their durability ensures a longer lifespan, contributing to reduced waste in landfills.

Applications of FRP Grating

FRP grating sheets are utilized across a broad spectrum of industries. Common applications include

- Chemical Plants To provide safe walkways and platforms that resist corrosive environments. - Marine Structures For docks, piers, and walkways where exposure to water and salt is a concern. - Food Processing Where hygiene and easy cleaning are paramount, FRP grating offers a non-porous surface that meets health standards. - Power Generation In power plants, especially within coal or nuclear facilities, where safety and durability are essential. - Wastewater Treatment Providing a safe, reliable surface that withstands harsh chemicals and conditions.

Installation of FRP Grating Sheets

Installing FRP grating sheets is straightforward, requiring minimal tools. They can be cut to size using standard cutting tools, and are often installed using a simple fastening system. The lightweight nature of FRP makes it easy for one or two people to handle and position the grating securely.

Conclusion

In summary, FRP grating sheets represent an innovative solution for a diverse range of applications, combining strength, durability, and resistance to environmental factors. As industries continue to seek materials that enhance safety and reduce maintenance costs, FRP grating stands out as a superior alternative, poised to meet the evolving challenges of modern construction and industrial processes.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025