loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

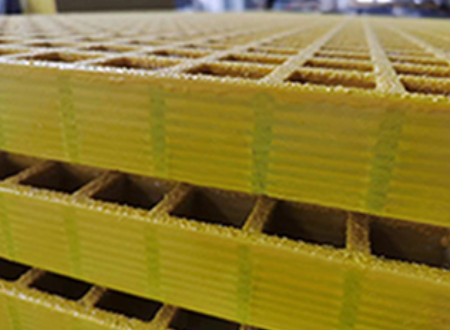

Frp Grating from Selection to Installation, Unlocking a Durable New Solution for Industrial Platforms

In the world of industrial flooring and structural platforms, FRP grating has emerged as a premier solution for environments where corrosion, slip resistance, and durability are paramount. This versatile material, championed by manufacturers like ZJ Composites who prioritize quality and innovation, offers exceptional performance where traditional steel grating would fail. For applications requiring superior strength, heavy duty FRP grating provides the necessary load-bearing capacity for industrial settings. When designed as a complete system, an FRP grating platform creates a safe, long-lasting work surface for walkways, mezzanines, and processing areas. However, understanding the factors influencing FRP grating price is crucial for making informed procurement decisions that balance budget with performance requirements. This comprehensive guide explores the technical specific

The Versatility and Advantages of Our Frp Grating

Our frp grating is engineered to address the core pain points of traditional grating materials, offering a balance of performance, safety, and ease of use for diverse applications.

Key Benefits of ZJ Composites’ frp grating:

- Superior Safety: Available with anti-slip surfaces (e.g., gritted or diamond-top designs), it prevents slips even in wet or oily conditions—critical for walkways, staircases, and production floors. It also meets ASTM E-84 flame-spread standards (rating ≤25) and ASTM D-635 extinguishing requirements, ensuring fire safety.

- Corrosion Resistance: Unlike steel, frp gratingresists rust, chemical erosion, and degradation in fresh/saltwater environments, making it ideal for marine projects, wastewater treatment plants, and chemical facilities.

- Lightweight & Easy Installation: Weighing 1/3 of steel, it reduces transportation and labor costs. No special tools or hot works are needed for on-site fabrication, cutting installation time by up to 40%.

- Low Maintenance: Tough and durable, it requires minimal upkeep (no painting, coating, or rust repairs), slashing long-term lifecycle costs compared to traditional materials.

ZJ Composites’ frp grating is available in standard, micro, and mini mesh designs, catering to needs from drainage gutters to equipment access grates.

The Robust Performance of Heavy Duty Frp Grating

Heavy duty frp grating is designed to withstand high loads and harsh operating conditions, making it the go-to choice for heavy-industry applications where strength and reliability are non-negotiable.

Features of Our heavy duty frp grating:

- Exceptional Strength-to-Weight Ratio: It offers load-bearing capacity comparable to steel (supporting 500–5,000 lbs/sq ft) while remaining lightweight, reducing structural stress on buildings or platforms.

- Impact Resistance: Unlike steel, it absorbs impacts without permanent deformation—critical for areas with heavy machinery, forklift traffic, or frequent equipment movement.

- Durable Construction: Manufactured with high-grade fiberglass and resin, it resists wear, UV damage, and chemical exposure, ensuring a service life of 15+ years even in harsh environments.

ZJ Composites leverages its perfect testing equipment to validate the load capacity of heavy duty frp grating, providing customers with detailed load tables for project compliance.

The Safety and Functionality of Frp Grating Platform

Frp grating platform is tailored to create secure, efficient workspaces for industrial and commercial settings, from mezzanines to offshore oil platforms.

Advantages of Our frp grating platform:

- Non-Conductive & Non-Magnetic: It does not conduct electricity or interfere with electromagnetic signals, making it safe for electrical substations, communication towers, and radar facilities.

- Customizable Design: We offer tailored sizes, mesh patterns, and edge treatments to fit irregular spaces (e.g., equipment enclosures or gantries). ZJ Composites’ technical team also provides detailed installation plans to ensure seamless integration.

- Long-Term Stability: Resists thermal expansion/contraction and environmental degradation, maintaining structural integrity even in extreme temperatures (-40℃ to 80℃).

Whether for new construction or platform retrofits, frp grating platform enhances worker safety while reducing operational costs.

Understanding Frp Grating Price: Value for Your Investment

While frp grating price may have a slightly higher initial cost than steel, its long-term value—driven by low maintenance, durability, and energy savings—makes it a cost-effective choice.

Factors Influencing frp grating price at ZJ Composites:

- Mesh Design & Surface Treatment: Standard mesh (e.g., 38×38mm) is more economical than micro mesh; anti-slip surfaces add a small premium but reduce accident risks and liability costs.

- Quantity & Customization: Factory-outlet pricing for bulk orders (100+ sq ft) offers 10–20% discounts; custom sizes/shapes incur minimal extra costs but optimize project efficiency.

- Application-Specific Upgrades: Special resin coatings for chemical resistance or UV protection may increase frp grating priceslightly but extend service life in harsh environments.

The table below compares frp grating price value with steel over a 10-year lifecycle:

|

Cost Category |

FRP Grating |

Steel Grating |

|

Initial Purchase Cost |

\(15–\)30/sq ft |

\(10–\)20/sq ft |

|

Annual Maintenance Cost |

\(2–\)5/sq ft |

\(15–\)25/sq ft |

|

10-Year Total Cost |

\(35–\)80/sq ft |

\(160–\)270/sq ft |

ZJ Composites’ factory-outlet model ensures competitive frp grating price without compromising quality, aligning with its goal of achieving win-win cooperation with customers.

FAQ About ZJ Composites’ FRP Grating Products

Can I request a custom size for frp grating?

Yes, ZJ Composites offers full customization for frp grating. We can tailor dimensions, mesh size, surface treatment (anti-slip or smooth), and load capacity to your project’s unique needs. Our technical team uses in-house testing equipment to validate custom designs, ensuring they meet your performance requirements. Simply share your project specs, and we’ll provide a detailed quote and sample.

What load capacity does heavy duty frp grating support?

Our heavy duty frp grating supports varying load capacities, from 500 lbs/sq ft (for light machinery access) to 5,000 lbs/sq ft (for heavy forklift traffic or equipment platforms). The exact capacity depends on mesh size (e.g., 50×50mm for higher loads) and material thickness. We provide detailed load tables for each product, and can conduct custom load tests if your project has specific requirements.

How do I install an frp grating platform?

Installing an frp grating platform is straightforward. ZJ Composites provides a step-by-step installation plan, including: 1) Measuring and cutting the grating to size with standard tools (circular saws or drills); 2) Securing it to steel/aluminum supports with FRP-compatible fasteners; 3) Sealing joints for water-tight applications (if needed). For complex projects, we can send engineers for on-site commissioning (customer bears travel/labor costs). No special training is required.

Are there any discounts on frp grating price for repeat customers?

Yes, ZJ Composites values long-term partnerships. Repeat customers qualify for 5–15% discounts on frp grating price, depending on order volume and frequency. Additionally, our factory-outlet program offers year-round competitive pricing, and holiday promotions (see our website for updates) provide extra savings. We also offer transparent quotes with no hidden fees, ensuring you get the best value.

What after-sales support do you provide for frp grating?

We stand behind our products with a 1-year free warranty for frp grating (covering manufacturing defects). Beyond that, we offer lifetime technical support—our team is available to answer installation questions, provide maintenance advice, or troubleshoot issues. This aligns with our customer service tenet of “continuously meeting customer needs and providing optimal solutions.” For urgent concerns, you can reach our support team 24/7 via phone or email.

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025