loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Analysis and Applications of Circular Hollow Section Steel in Structural Engineering

Circular Hollow Section Steel Overview and Applications

Circular Hollow Section (CHS) steel, often referred to as tube steel, is a versatile and efficient structural material widely used in construction and engineering applications. Characterized by its hollow circular cross-section, CHS steel has gained popularity due to its high strength-to-weight ratio, aesthetic appeal, and excellent resistance to torsion. This article explores the advantages, manufacturing processes, and applications of circular hollow section steel.

Advantages of Circular Hollow Section Steel

One of the primary advantages of CHS steel is its structural efficiency. The circular shape distributes loads uniformly, reducing stress concentrations at critical points. This allows for longer spans and less material usage compared to traditional shapes like I-beams or rectangular hollow sections, contributing to cost savings and lighter structures.

Furthermore, CHS steel exhibits superior performance in various loading conditions. Its design allows for effective resistance to torsion, making it ideal for applications that require high twisting strength. Additionally, the rounded edges of CHS reduce stress concentration, thus enhancing durability and fatigue resistance in dynamic loading situations.

Another notable benefit is the aesthetic versatility that CHS steel offers. The smooth, cylindrical shape results in a modern and clean appearance, making it a popular choice for architectural applications. From exposed structural elements to railings and handrails, CHS steel enhances the visual appeal of any structure while providing robust support.

Manufacturing Processes

Circular hollow section steel is typically manufactured through two primary methods hot-rolled and cold-formed processes

.1. Hot-Rolled CHS This process involves heating steel slabs and then rolling them into the desired shape while hot. The resulting material is known for its toughness and ductility, which are essential characteristics in heavy-duty applications. Hot-rolled CHS is often used in structural applications that demand high strength.

2. Cold-Formed CHS In this process, flat steel sheets are cold-rolled into tubular shapes at room temperature. Cold-formed CHS sections are generally lighter and have a smoother finish compared to hot-rolled sections. They are commonly used in lighter constructions such as residential buildings, interior framing, and decorative applications.

circular hollow section steel

Both manufacturing processes result in high-quality, uniform products that can be customized in terms of size and thickness to meet specific engineering requirements.

Applications of Circular Hollow Section Steel

CHS steel is used across a wide range of industries, reflecting its adaptability and performance characteristics. Some of the critical applications include

1. Construction In building frameworks, CHS is commonly used for columns, beams, and trusses. Its structural integrity is vital for high-rise buildings, bridges, and industrial structures where strength and weight considerations are crucial.

2. Automotive Industry CHS steel is increasingly being employed in the automotive sector for manufacturing rolled sections, chassis, and roll cages. Its strength and lightweight properties contribute to improved fuel efficiency and safety.

3. Furniture Design The aesthetic quality of CHS steel has made it a popular choice in modern furniture design. Tables, shelves, and seating often incorporate CHS for both structural support and visual appeal.

4. Marine Applications Due to its excellent corrosion resistance, CHS steel is suitable for marine applications, such as shipbuilding and offshore structures, where exposure to harsh environments is a concern.

5. Sports and Recreational Facilities Many sports structures, including stadium roof designs and outdoor canopies, utilize CHS steel due to its ability to combine strength and style seamlessly.

Conclusion

Circular Hollow Section steel is a quintessential material in modern construction and engineering, offering a blend of structural integrity, aesthetic appeal, and versatility. Its benefits in load distribution, aesthetic quality, and resistance to torsion make it an attractive choice for many applications. As industries evolve, the demand for efficient and sustainable materials like CHS steel will continue to grow, paving the way for innovative designs and groundbreaking construction methods. Whether in skyscrapers, bridges, or furniture, circular hollow section steel remains a fundamental element in shaping the built environment.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

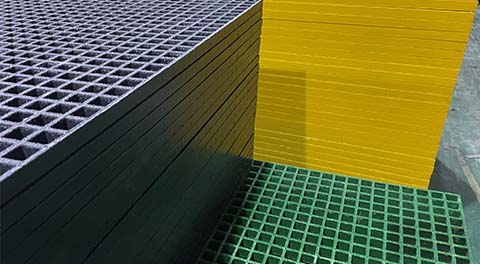

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025