loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Benefits and Applications of FRP Profiles in Modern Engineering

Understanding FRP Profiles A Comprehensive Overview

Fiber Reinforced Polymer (FRP) profiles are increasingly recognized for their unique properties and applications in various industries. These materials, composed of a polymer matrix reinforced with fibers, offer a combination of strength, durability, and lightweight characteristics that make them suitable for a wide range of uses. This article will explore the essential aspects of FRP profiles, their benefits, applications, and future prospects.

What Are FRP Profiles?

FRP profiles are structural components made from a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. The combination of these materials results in a composite that is not only strong but also highly resistant to environmental degradation, such as corrosion from chemicals and moisture. This makes FRP profiles particularly appealing in applications where traditional materials, like steel or concrete, may falter over time.

Benefits of FRP Profiles

1. Lightweight Nature One of the most significant advantages of FRP profiles is their lightweight property. Compared to traditional materials, FRP is much lighter, which reduces transportation costs and makes installation significantly easier. This lightweight nature is particularly beneficial in construction and manufacturing sectors.

2. Corrosion Resistance FRP profiles are highly resistant to corrosion and chemical attacks. This characteristic is especially advantageous in industries such as marine, chemical processing, and wastewater management, where exposure to harsh environments is commonplace.

3. High Strength-to-Weight Ratio FRP composites boast an excellent strength-to-weight ratio, meaning they can bear heavy loads while remaining lightweight. This feature is crucial in applications like bridges and building components, where structural integrity is paramount.

4. Customization FRP profiles can be easily customized in terms of shapes, sizes, and properties during the manufacturing process. This versatility allows for tailored solutions to meet specific engineering requirements, which is often challenging with traditional materials.

5. Thermal and Electrical Insulation Unlike metals, FRP profiles provide excellent thermal and electrical insulation, making them suitable for applications where temperature and electrical conductivity are concerns.

frp profiles

Applications of FRP Profiles

FRP profiles find applications in various sectors, including

- Construction Used for beams, columns, and reinforcement bars, FRP helps create structures that are both strong and resistant to environmental factors. They are particularly useful in coastal regions where saltwater exposure can lead to deterioration in conventional materials.

- Transportation In the automotive and aerospace industries, lightweight FRP components help enhance fuel efficiency and performance while maintaining safety standards.

- Marine FRP is widely used in boat building and marine structures due to its resistance to saltwater and corrosion.

- Energy Wind turbine blades and other energy-related components utilize FRP profiles because of their lightweight nature and strength, which help optimize performance and reduce maintenance costs.

Future Prospects

The future of FRP profiles looks promising, especially with ongoing research and development efforts aimed at improving composite materials. Innovations in manufacturing processes, such as automated fiber placement and 3D printing, are expected to enhance the efficiency and versatility of FRP profiles. Furthermore, as sustainability becomes a more pressing concern, the development of bio-based polymers and recycled fibers for FRP manufacturing could open new avenues for environmentally friendly construction and manufacturing practices.

In conclusion, FRP profiles represent a strong, lightweight, and durable option for various structural and industrial applications. Their unique properties not only enhance performance but also provide solutions to some of the challenges that traditional materials face. As technology advances, we can expect FRP profiles to play an increasingly vital role in shaping the future of construction, transportation, and beyond.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

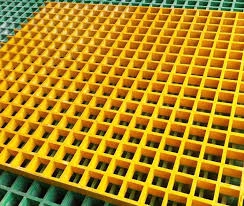

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025