loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

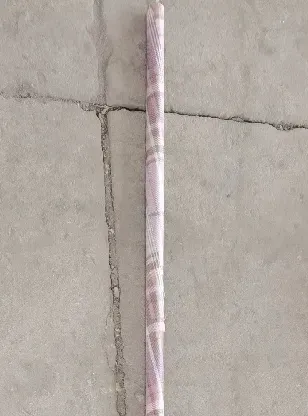

gfrp rod

The Versatility and Applications of GFRP Rods

Glass Fiber Reinforced Polymer (GFRP) rods have garnered significant attention in various industries due to their superior strength, durability, and lightweight characteristics. These composite materials, formed by embedding glass fibers in a polymer matrix, exhibit remarkable resistance to corrosion, making them a preferred choice for numerous applications, ranging from construction to aerospace.

Properties of GFRP Rods

One of the most appealing features of GFRP rods is their excellent tensile strength, which often surpasses that of traditional materials like steel. This property allows GFRP rods to withstand substantial loads without deformation. Moreover, their lightweight nature makes them easier to transport and handle, ultimately reducing labor costs in construction and manufacturing processes.

Another significant advantage of GFRP rods is their resistance to chemical and environmental degradation. Unlike steel, which can corrode when exposed to moisture and harsh chemicals, GFRP rods maintain their integrity even in extreme conditions. This resistance makes them particularly valuable in applications that involve exposure to seawater, aggressive chemicals, or damp environments.

Applications in Construction

In the construction industry, GFRP rods are increasingly utilized as reinforcement materials in concrete structures. Their application can be seen in bridges, parking garages, and high-rise buildings, where they provide strength and stability without adding excessive weight. The use of GFRP rods in concrete not only enhances structural performance but also prolongs the lifespan of constructions by preventing rust formation.

Furthermore, GFRP rods can be used in retrofitting existing structures. By integrating these rods into aging buildings or infrastructure, engineers can significantly improve their load-bearing capacity and extend their useful life. This application is particularly relevant in areas prone to seismic activity, where the flexibility and strength of GFRP can effectively counteract destructive forces during an earthquake.

gfrp rod

Benefits in the Marine Industry

The marine industry has also embraced GFRP rods for their exceptional durability in corrosive environments. Shipbuilding and repair often require materials that can withstand the harsh conditions of the sea, and GFRP rods fit this description perfectly. They are commonly used in the construction of boats, docks, and other marine structures, offering a lightweight alternative to traditional materials that can corrode over time.

Additionally, GFRP rods serve as effective reinforcement for anchoring systems in marine applications. Their resistance to saltwater corrosion ensures the longevity and reliability of mooring lines and other anchoring systems, which are essential for the stability of marine vessels.

GFRP in Aerospace and Automotive Industries

In the aerospace and automotive sectors, the need for lightweight yet robust materials is crucial to improve fuel efficiency and performance. GFRP rods are employed in various components, including wings, fuselages, and chassis. By replacing heavier materials, manufacturers can reduce overall weight, leading to improved aerodynamics and decreased energy consumption.

Moreover, the customization potential of GFRP allows for manufacturing parts with complex shapes and sizes. This adaptability opens up new possibilities in design, enabling engineers to innovate and create parts that were previously difficult to fabricate.

Conclusion

The growing adoption of GFRP rods across diverse industries highlights their significance as a versatile and reliable material. With benefits such as high tensile strength, lightweight properties, and resistance to corrosion, GFRP rods are reshaping conventional practices in construction, marine, aerospace, and automotive applications. As technology continues to advance, we can anticipate even greater innovations in the use of GFRP materials, making them an integral part of the modern manufacturing landscape. With ongoing research and development, GFRP rods are set to play a pivotal role in the future of engineering solutions, aligning with the global emphasis on sustainability and efficiency.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025