loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Specifications for SMC Panel Tank and Its Features Overview

Understanding SMC Panel Tank Specifications

In recent years, SMC (Sheet Molding Compound) panel tanks have gained popularity in various industries due to their versatility, durability, and cost-effectiveness. These tanks are particularly notable for their applications in water storage, wastewater treatment, and chemical storage. This article delves into the specifications of SMC panel tanks, exploring their construction, advantages, and the factors to consider when selecting them.

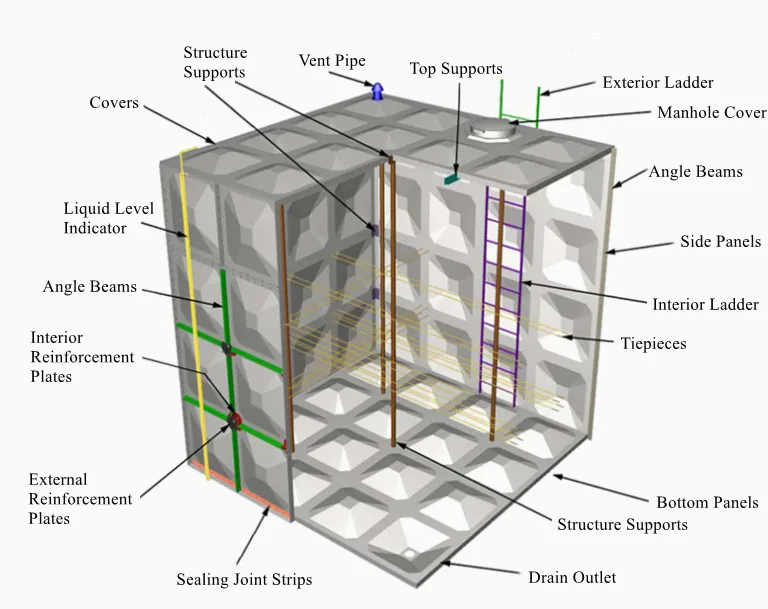

Construction of SMC Panel Tanks

SMC panel tanks are primarily composed of prefabricated panels made from a composite material that combines fiberglass, resin, and fillers. This composition imparts numerous beneficial properties to the tanks, such as high strength-to-weight ratio, excellent corrosion resistance, and superior insulation abilities.

The panels are typically manufactured in standard sizes, allowing for easy transportation and installation. They are available in various thicknesses, which can influence the tank's overall strength and durability. The panels are designed to fit together seamlessly through a tongue-and-groove system, ensuring water tightness and structural integrity.

In addition to the panels, SMC tanks often feature various accessories, including manholes, inlet and outlet pipes, and overflow systems. The installation of these tanks is relatively straightforward, often requiring only a flat, stable base for support. This ease of assembly reduces labor costs and timeframes associated with construction projects.

Advantages of SMC Panel Tanks

One of the most significant advantages of SMC panel tanks is their resistance to corrosion and chemical damage. Unlike traditional materials such as steel or concrete, SMC panels do not rust, enabling them to maintain their integrity even when exposed to harsh environments. This property is particularly critical in applications involving wastewater or aggressive chemicals.

Another key benefit is the material's lightweight nature, making SMC tanks easier to handle and install. Their design allows for customization in terms of size and shape, accommodating specific site requirements or storage needs.

Additionally, SMC tanks offer exceptional thermal insulation, which helps maintain the temperature of the stored liquids. This feature is crucial for industries requiring temperature-controlled environments, such as food and beverage production, pharmaceuticals, and chemical processing.

Furthermore, the panels are produced using advanced molding techniques, which ensure consistent quality and performance across the board. The longevity of SMC tanks, combined with lower maintenance requirements, presents a more economical choice in the long run.

smc panel tank specifications

Key Specifications to Consider

When evaluating SMC panel tanks, several specifications must be taken into account to ensure the selected product meets the intended requirements

1. Capacity SMC tanks come in various capacities, typically ranging from a few hundred liters to several million liters. It’s vital to select the right capacity based on the intended usage.

2. Panel Thickness The thickness of the panels directly impacts the tank's strength and durability. Thicker panels provide added resistance to external pressures, making them suitable for more demanding applications.

3. Pressure Ratings Depending on the application, SMC tanks may be required to withstand different pressures (both internal and external). Understanding the pressure requirements is essential for selecting a suitable tank.

4. Temperature Resistance SMC materials can endure a range of temperatures. However, understanding the temperature limits of the specific tank is crucial, especially in industrial settings or areas subjected to extreme weather conditions.

5. Quality Certifications Look for SMC tanks that comply with industry standards and certifications. This validation ensures that the product meets safety, quality, and environmental standards.

6. Warranty and Service A good warranty can provide peace of mind regarding the tank’s longevity and performance. Additionally, consider vendors that offer reliable customer service and support.

Conclusion

SMC panel tanks represent an innovative solution for various storage needs across multiple industries. Their lightweight construction, durability, resistance to corrosion, and ease of installation make them an attractive option compared to traditional storage solutions. By understanding the specifications and considering various factors when selecting an SMC tank, businesses can ensure they invest in a reliable product that meets their specific requirements, ultimately leading to increased efficiency and reduced operational costs in their storage solutions.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025