loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Micro Mesh Grating | Anti-Slip, Corrosion-Resistant FRP

Micro Mesh Grating is a key solution in the manufacturing industry, specifically within plastic product industry and Enhance the manufacturing of plastic products. This article explores how Zhaojia Composites Co., Ltd supports professionals with durable, high-performance products, and explains why this product is an ideal choice for businesses in these sectors.

Table of Contents

- Micro Mesh Grating Overview

- Benefits & Use Cases of Micro Mesh Grating in Enhance the manufacturing of plastic products

- Cost, Maintenance & User Experience

- Sustainability & Market Trends in manufacturing

- Conclusion on Micro Mesh Grating from Zhaojia Composites Co., Ltd

Micro Mesh Grating Overview

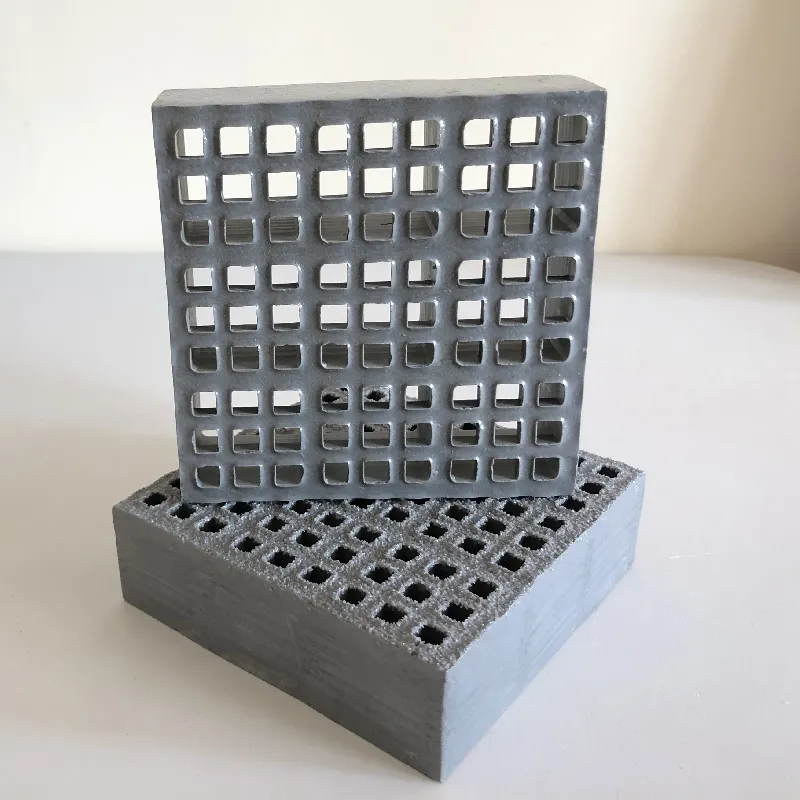

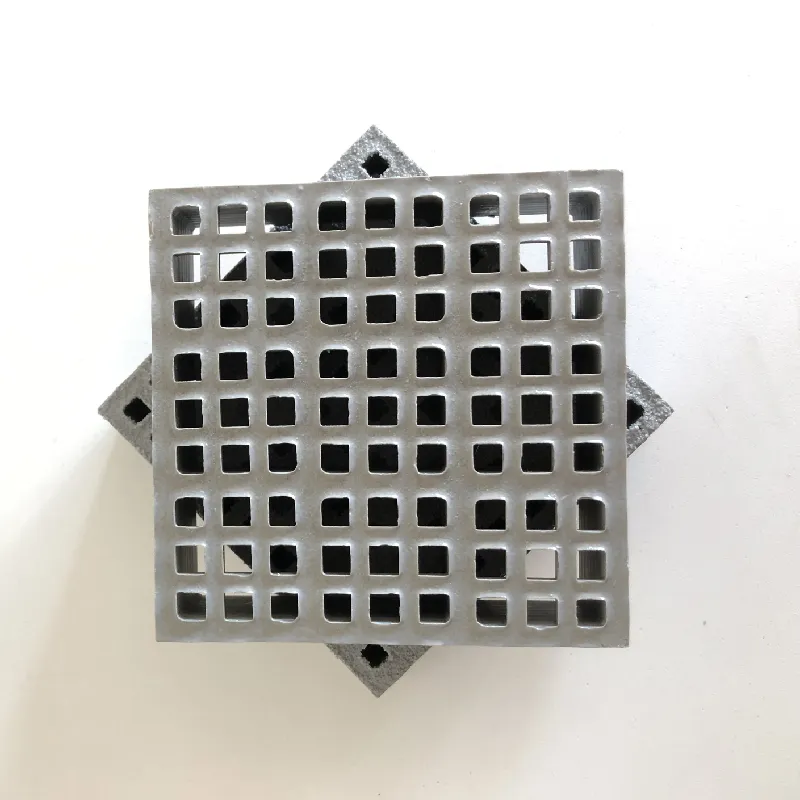

Micro Mesh Grating is a molded FRP (fiberglass-reinforced plastic) grating with small apertures designed to prevent tool, part, and heel fall-through while providing a high-friction, non-conductive walking surface. In the plastic product industry, where floors are often exposed to chemicals, lubricants, moisture, and fine debris, Micro Mesh Grating delivers reliable load-bearing performance and slip resistance without the corrosion and maintenance burden of steel. Its tight mesh pattern supports carts and small-wheeled equipment and is ideal for work platforms, assembly lines, mezzanines, and trench covers across injection molding, extrusion, compounding, and finishing areas.

- Relevance: Combines high strength-to-weight ratio, electrical insulation, and corrosion resistance to meet safety and uptime goals in modern manufacturing.

- Technical background: Molded construction with continuous glass fiber reinforcement; multiple resin options (e.g., polyester or vinyl-ester), anti-slip gritted surface, and UV-stabilized finish; available in different thicknesses and panel sizes for custom layouts.

- Manufacturing credibility: Zhaojia Composites Co., Ltd—a trusted name among FRP grating suppliers—delivers consistent quality, tight tolerances, and responsive engineering support for tailored installations.

Benefits & Use Cases of Micro Mesh Grating in Enhance the manufacturing of plastic products

In plastic manufacturing environments, Micro Mesh Grating solves common facility challenges—safety, corrosion, and cleanliness—while supporting continuous operation. The small aperture limits debris accumulation and improves walking comfort, and the molded FRP grating structure resists chemicals found in cooling, cleaning, and processing applications. Its non-sparking, non-magnetic nature makes it appropriate around sensitive equipment, and the gritted surface helps reduce slip incidents in wet or oily areas.

- Applications: Walkways along molding cells, mezzanines over extrusion lines, inspection platforms, washdown zones, wastewater pits, coolant trenches, and chemical storage areas.

- Advantages: Lightweight panels speed installation; corrosion/UV resistance prolongs service life; micro apertures prevent small-part drop-through; electrical insulation enhances worker safety; low thermal conductivity improves comfort.

- Expertise: Zhaojia Composites Co., Ltd engineers support load calculations, panel nesting, and edge/band finishing to optimize cost, safety, and compliance for each site—helping B2B decision makers standardize FRP grating across plants.

Cost, Maintenance & User Experience

Total cost of ownership is where Micro Mesh Grating excels. Compared with painted or galvanized steel, FRP grating typically eliminates recurring surface prep, painting, and corrosion-related replacement, which lowers lifecycle costs. Lightweight panels often reduce installation labor and crane time, and the ability to field-cut with standard tools helps teams adapt on site without delays. Over the service life, reduced maintenance shutdowns, fewer slip incidents, and dependable chemical resistance contribute to a compelling ROI for safety, reliability, and compliance budgets.

- Durability & ROI: Extended service life in corrosive plant zones means fewer replacements and predictable OPEX.

- Customer feedback: Plastic product industry users report cleaner walkways after washdowns, better traction in coolant areas, and faster installs than comparable metal systems. Many standardize on FRP grating across facilities to streamline maintenance and spares.

Sustainability & Market Trends in manufacturing

Manufacturers are aligning capital projects with ESG goals, favoring materials that reduce repainting, extend service life, and minimize downtime and waste. Micro Mesh Grating supports this direction by resisting corrosion without routine coatings and by maintaining performance in harsh plant environments. The market for FRP solutions continues to grow as EHS teams seek non-conductive, slip-resistant platforms that improve worker safety while reducing maintenance emissions (e.g., from blasting and painting). Specifying durable FRP grating helps lower replacement frequency and waste generation over time.

- Regulatory context: Safer walking-working surfaces and chemical exposure controls are ongoing priorities; FRP grating’s stable performance aids compliance strategies.

- Leadership: Zhaojia Composites Co., Ltd continually refines resin systems and surface finishes to balance performance, longevity, and environmental considerations—positioning the company among forward-thinking FRP grating suppliers for sustainable plant upgrades.

Conclusion on Micro Mesh Grating from Zhaojia Composites Co., Ltd

Micro Mesh Grating provides a proven, high-value upgrade for manufacturing facilities, especially in the plastic product industry where safety, cleanliness, and uptime matter most. By choosing molded FRP grating from Zhaojia Composites Co., Ltd, B2B decision makers gain long-term durability, strong slip resistance, corrosion protection, and installation efficiency—all with less maintenance than traditional metal systems. Backed by responsive engineering and service, Zhaojia delivers reliable performance at scale.

- Value recap: Strong, lightweight, corrosion-resistant Micro Mesh Grating enhances worker safety and lowers lifecycle costs.

- Reputation: Zhaojia Composites Co., Ltd stands out among FRP grating suppliers for quality and support.

- Strong CTA: Contact us: email: admin@zjcomposites.com – Visit our website: https://www.zjcomposites.com

-

Revolutionizing Industrial Safety with ZJ Composites' Mini Mesh GratingNewsNov.14,2025

-

Premium FRP Profiles and FRP Grating Revolution for Global WholesalersNewsNov.14,2025

-

Ultimate Strength with ZJ Composites FRP Profiles for Wholesale SuccessNewsNov.14,2025

-

ZJ Composites Covered Grating – The Durable Flooring Solution for Smarter Industrial SpacesNewsNov.14,2025

-

Mini Mesh Grating Enhancing Strength and Style in Every ProjectNewsNov.14,2025

-

FRP Pressure Vessels by ZJ CompositesNewsNov.14,2025

-

Transforming Industrial Spaces with Advanced Frp GratingNewsNov.11,2025