loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

liquid filter vessel

Understanding Liquid Filter Vessels A Comprehensive Guide

Liquid filter vessels are essential components in various industrial processes, where the purity of liquids is paramount. These filtration systems are designed to remove contaminants, particles, and impurities from liquids, ensuring that the final product meets specified quality standards. This article explores the critical aspects of liquid filter vessels, their operation, design considerations, and applications across different industries.

What is a Liquid Filter Vessel?

A liquid filter vessel is a holding tank or chamber equipped with filtration systems that allow liquids to flow through while trapping unwanted substances. The vessel typically consists of a durable exterior designed to withstand the pressure and chemical composition of the fluids being filtered. Inside, various filter media such as filter bags, cartridges, or membranes are used to capture particles ranging from large debris to microscopic contaminants.

How Liquid Filter Vessels Work

The operation of a liquid filter vessel usually involves the following steps

1. Inlet Flow The unfiltered liquid enters the vessel through an inlet pipe, where it is directed toward the filter media.

2. Filtration Process As the liquid passes through the filter media, contaminants are captured, allowing only clean liquid to exit the vessel. The filtration efficiency depends on the type of filter media used and the particle size distribution of the contaminants.

3. Outlet Flow The filtered liquid exits the vessel through an outlet pipe, ready for further processing or use.

4. Backwashing/Replacement Depending on the filter design, the system may allow for backwashing (reversing the flow to clean the filter) or require the replacement of the filter media after a certain period or when a defined pressure drop indicates clogging.

Design Considerations

When designing a liquid filter vessel, several factors must be taken into account to ensure optimal performance

- Material Selection The material of construction should be compatible with the liquid being filtered. Common materials include stainless steel, carbon steel, and various plastics, each chosen for their resistance to corrosion, temperature, and pressure.

liquid filter vessel

- Filtration Method The choice of filtration method—such as depth filtration, surface filtration, or membrane filtration—depends on the specific application and the type of contaminants present in the liquid.

- Flow Rate It’s essential to calculate the required flow rate and pressure drop across the filter media to ensure that the system meets operational demands efficiently.

- Accessibility The design should allow for easy maintenance, including access to the filter media for cleaning or replacement.

- Safety Measures Safety features must be integrated into the design, including pressure relief valves and proper sealing mechanisms to prevent leaks.

Applications of Liquid Filter Vessels

Liquid filter vessels are widely used in various industries

- Food and Beverage In food processing, maintaining product purity is critical. Liquid filter vessels are used to ensure that ingredients are free from contaminants that could compromise flavor and safety.

- Water Treatment Municipal and industrial water treatment facilities employ these filter vessels to remove sediments, bacteria, and other impurities from water to meet health regulations.

- Chemical Processing In the chemical industry, liquid filter vessels help to protect equipment and improve the quality of the final product by removing undesired particles from process liquids.

- Pharmaceuticals High purity is essential in pharmaceutical manufacturing. Liquid filter vessels are employed to ensure that drugs are free from any particulate contamination.

- Oil and Gas In oil and gas extraction and processing, filter vessels remove solids and impurities from fluids used in drilling and refining processes.

Conclusion

Liquid filter vessels play a critical role in maintaining product quality across various industries by ensuring that liquids are free from harmful contaminants. From their design considerations to their applications, understanding these vessels is key for engineers, operators, and quality assurance professionals. As technology advances, innovations in filtration methods and materials continue to enhance the effectiveness and efficiency of liquid filter vessels, making them indispensable in the quest for purity and safety in liquid processing.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

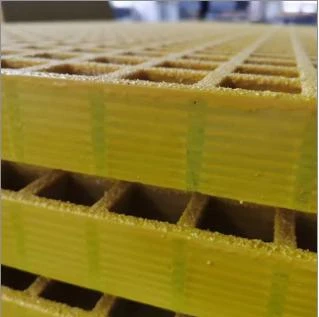

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025