loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

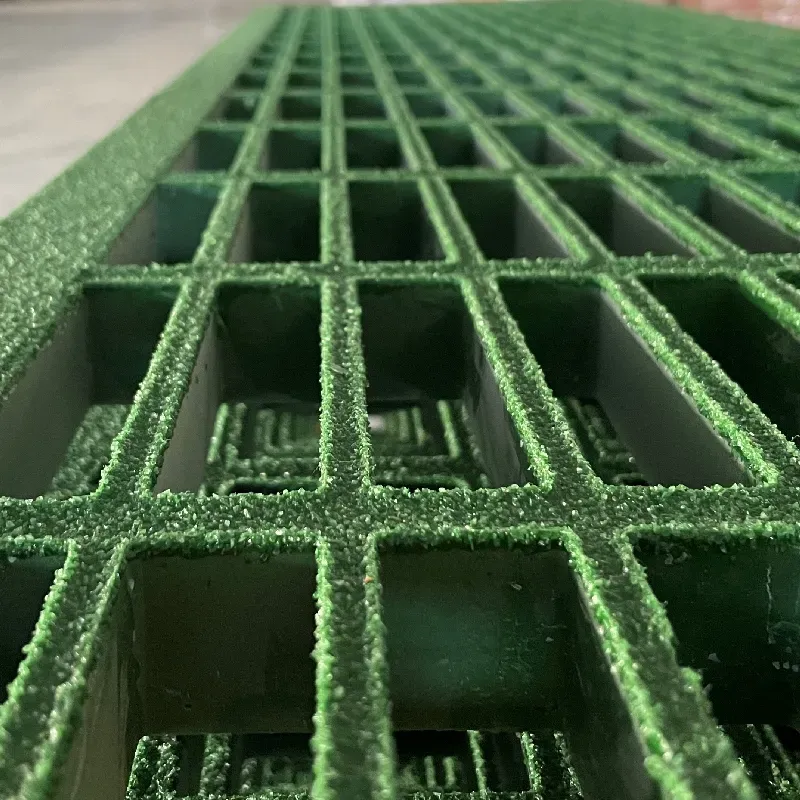

Durable FRP Grating Solutions for Industrial Applications and Heavy-Duty Use

The Advantages of Heavy Duty FRP Grating

In many industrial applications, the choice of materials is crucial to ensure safety, durability, and cost-effectiveness. One such material that has gained prominence in recent years is heavy-duty fiberglass reinforced plastic (FRP) grating. This material offers a plethora of benefits that make it an excellent choice for various environments, particularly where strength and resistance to environmental factors are required.

What is Heavy Duty FRP Grating?

Heavy-duty FRP grating is a composite material made from fiberglass and resin, which comes together to create a strong, lightweight structure. It is designed to support heavy loads while providing a solid walking surface. The structure typically consists of a grid pattern that permits the flow of liquids and enhances drainage. This feature makes it an ideal solution for industries such as wastewater treatment, chemical processing, food and beverage, and marine applications.

Benefits of Heavy Duty FRP Grating

1. Load-Bearing Capacity As the name suggests, heavy-duty FRP grating is specifically engineered to support substantial weights. This characteristic is vital in industrial settings where heavy machinery, equipment, and foot traffic are commonplace. The load-bearing capacity of FRP grating often surpasses that of traditional materials like steel or aluminum, making it a reliable option for various applications.

2. Corrosion Resistance One of the most significant advantages of FRP grating is its exceptional resistance to corrosion. Unlike metal gratings that can oxidize and degrade over time, FRP grating does not rust. This property is particularly valuable in environments exposed to chemicals, moisture, and acidic conditions. With an FRP system, industries can expect a longer lifespan and reduced maintenance costs, as the need for replacements due to corrosion is significantly diminished.

heavy duty frp grating

3. Lightweight Nature The lightweight quality of FRP grating makes it easier to handle and install. This aspect not only accelerates the installation process but also reduces labor costs. Additionally, the reduced weight lowers transportation expenses, making FRP a cost-effective alternative to heavier materials.

4. Safety Features Safety is a paramount concern in industrial environments. Heavy-duty FRP grating offers a non-slip surface that enhances traction, minimizing the risk of slips and falls. This characteristic is essential in environments that may become wet or oily, making it a preferred option for walkways, platforms, and stair treads. Moreover, FRP grating does not conduct electricity, providing an additional layer of safety in electrical installations.

5. Environmental Considerations FRP materials are often hailed for their environmentally friendly attributes. The manufacturing processes of FRP can be done in a manner that minimizes waste, and many suppliers offer recycling options for end-of-life products. Choosing heavy-duty FRP grating can contribute to a more sustainable operation within industries known for their environmental impact.

6. Versatility Heavy-duty FRP grating comes in various shapes, sizes, and colors, allowing for customization to suit specific project needs. Its versatility enables it to be employed in diverse settings, whether it’s a chemical plant, a commercial kitchen, or an outdoor recreational area. This adaptability extends beyond industrial applications, as architects and designers increasingly recognize the aesthetic appeal of FRP grating.

Conclusion

In conclusion, heavy-duty FRP grating emerges as a superior choice for industries requiring durable, safe, and reliable flooring solutions. Its combination of load-bearing capacity, corrosion resistance, lightweight properties, and safety features make it indispensable in modern infrastructure. As industries continue to prioritize safety and efficiency, the adoption of heavy-duty FRP grating is likely to increase, paving the way for a safer and more sustainable future. Whether in construction, manufacturing, or environmental management, investing in heavy-duty FRP grating may very well prove to be a wise decision for companies looking to optimize their operations.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025