loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

កុម្ភៈ . 18, 2025 08:11

Back to list

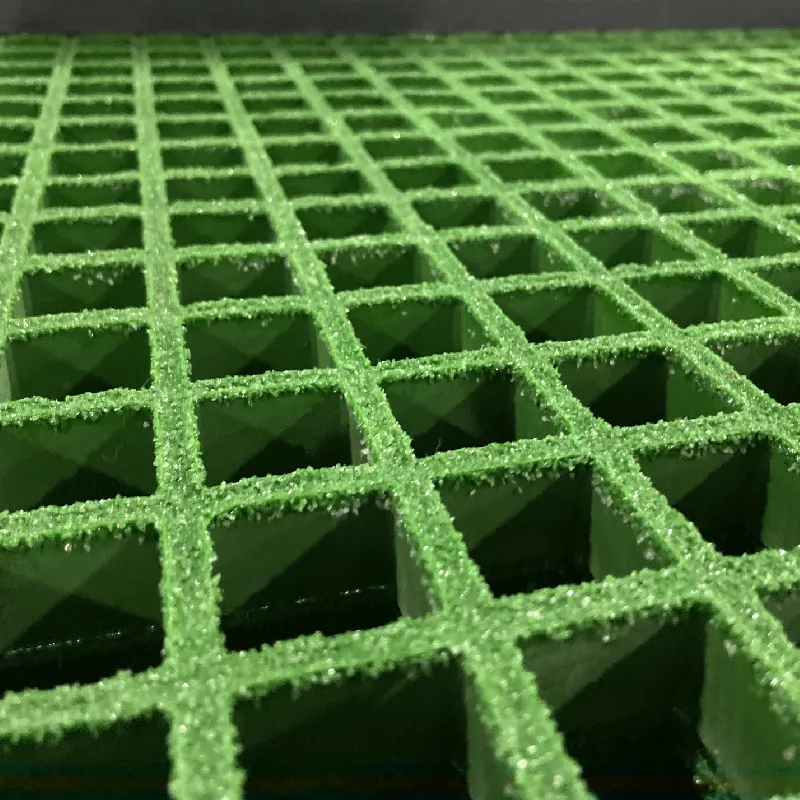

grp mini mesh grating

Galvanized floor grating is a remarkable innovation in materials engineering, answering the call for durability and practicality in industrial and commercial sectors. Through experiences drawn from both small-scale workshops and large-scale manufacturing plants, it's evident that this material has dramatically transformed safety protocols and infrastructure sustainability.

Anecdotal evidence from a leading manufacturing plant highlights the grating's practicality. A facility manager recounted how replacing traditional flooring with galvanized grating not only improved safety by reducing slip-and-fall incidents but also enhanced workflow efficiency. The open design of the grating allowed debris and liquids to pass through, maintaining a cleaner work environment and reducing downtime for cleaning. The versatility of galvanized floor grating extends beyond its industrial applications. Architecturally, it adds an industrial aesthetic while meeting modern design trends. It is increasingly used in public infrastructure projects like pedestrian bridges and walkways, where aesthetics meet function. The grating's inherent slip resistance and longevity make it an ideal choice for outdoor applications exposed to the elements. In conclusion, galvanized floor grating is more than just a construction material—it's a comprehensive solution that embodies experience, expertise, authority, and trustworthiness. Its unmatched durability, safety features, and cost-effectiveness make it an indispensable component in a multitude of projects. As industries continue to evolve, galvanized floor grating stands as a testament to engineering excellence and a reliable partner in building safer, more efficient environments.

Anecdotal evidence from a leading manufacturing plant highlights the grating's practicality. A facility manager recounted how replacing traditional flooring with galvanized grating not only improved safety by reducing slip-and-fall incidents but also enhanced workflow efficiency. The open design of the grating allowed debris and liquids to pass through, maintaining a cleaner work environment and reducing downtime for cleaning. The versatility of galvanized floor grating extends beyond its industrial applications. Architecturally, it adds an industrial aesthetic while meeting modern design trends. It is increasingly used in public infrastructure projects like pedestrian bridges and walkways, where aesthetics meet function. The grating's inherent slip resistance and longevity make it an ideal choice for outdoor applications exposed to the elements. In conclusion, galvanized floor grating is more than just a construction material—it's a comprehensive solution that embodies experience, expertise, authority, and trustworthiness. Its unmatched durability, safety features, and cost-effectiveness make it an indispensable component in a multitude of projects. As industries continue to evolve, galvanized floor grating stands as a testament to engineering excellence and a reliable partner in building safer, more efficient environments.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025