loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp vessel price

The Price Dynamics of FRP Vessels Understanding the Market

FRP, or Fiber Reinforced Plastic, has gained considerable traction in various industries due to its unique properties, such as high strength-to-weight ratio, corrosion resistance, and adaptability. These characteristics make FRP vessels an attractive option for a range of applications, including storage tanks for chemicals, water treatment systems, and even marine applications. As the demand for these materials increases, it becomes essential to understand the pricing dynamics in the FRP vessel market.

Factors Influencing FRP Vessel Prices

The pricing of FRP vessels is influenced by a multitude of factors. One of the primary determinants is the raw material costs. FRP is typically composed of a polymer matrix reinforced by fibers, which can be made from glass, carbon, or aramid. The prices of these raw materials fluctuate based on global supply and demand dynamics, production costs, and trade policies. For example, factors such as oil prices directly affect the cost of the resins used in making FRP. When oil prices rise, resin costs increase, which in turn drives up the price of FRP vessels.

Another important factor is the production methods employed in manufacturing FRP vessels. Advanced techniques such as filament winding and resin transfer molding can enhance the mechanical properties of the final product but may also increase production costs. Consequently, manufacturers that invest in state-of-the-art technology might charge higher prices for their FRP vessels, as they offer superior quality and durability.

Labor costs also contribute significantly to the final pricing of FRP vessels. Depending on the region, labor costs can vary widely, impacting overall production expenses. Regions with highly skilled labor may have higher wages, yet they can leverage this expertise to produce higher quality vessels, which could justify a premium price tag.

Market Trends and Their Impact

frp vessel price

The demand for FRP vessels has been on an upward trajectory, driven by the expanding industrial and infrastructural applications across various sectors. The water treatment industry, in particular, has seen a significant rise in the demand for FRP tanks, primarily due to their resistance to corrosion and lower maintenance requirements compared to traditional materials like steel. Similarly, industries involved in chemical storage are increasingly opting for FRP vessels to comply with stringent safety regulations and to mitigate the risk of contamination.

Regional trends also play an influential role in determining the price of FRP vessels. For instance, the Asia-Pacific region has emerged as a significant market for FRP vessels, fueled by rapid industrialization and infrastructural growth. Countries like China and India have seen a surge in demand for FRP products, resulting in increasing competition among manufacturers, which can have a downward effect on prices.

Competitive Landscape

The competitive landscape of the FRP vessel market is characterized by a mix of well-established players and emerging firms. Established manufacturers often leverage their brand reputation and experience to command higher prices. In contrast, newer entrants may adopt competitive pricing strategies to gain market share. This dynamic leads to variations in pricing, even for similar products, and can benefit consumers through more options and potentially lower costs.

Conclusion

The pricing of FRP vessels is a complex interplay of various factors, including raw material costs, production methods, labor costs, and market demand. As industries continue to recognize the advantages of FRP, it is likely that market dynamics will evolve, resulting in changing price structures. For businesses looking to invest in FRP vessels, understanding these factors will be crucial in making informed purchasing decisions. As the market grows, staying updated on trends and pricing will help stakeholders navigate this essential sector more effectively. Ultimately, FRP vessels represent a significant investment, but their long-term benefits often outweigh initial costs, making them an invaluable asset across numerous applications.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

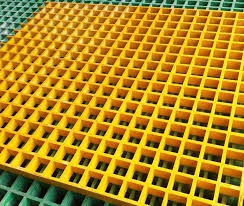

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025