loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp rod price

Understanding the Pricing Dynamics of FRP Rods

Fiber Reinforced Polymer (FRP) rods have gained considerable traction across various industries due to their excellent mechanical properties, durability, and lightweight nature. These composite materials, made from a polymer matrix reinforced with fibers, are employed in a wide range of applications, including construction, automotive, aerospace, and marine sectors. As demand for these versatile rods continues to rise, understanding the factors that influence their prices is essential for industry stakeholders, manufacturers, and consumers alike.

Factors Influencing FRP Rod Prices

1. Material Composition The primary constituents of FRP rods, which include the type of polymer and reinforcing fibers, substantially affect their cost. Commonly used fibers such as glass, carbon, or aramid have different pricing structures based on their availability, manufacturing processes, and performance characteristics. For instance, carbon fiber tends to be more expensive compared to glass fiber due to its superior strength-to-weight ratio and additional processing requirements.

2. Manufacturing Processes The method employed in the production of FRP rods can impact their price significantly. Different manufacturing techniques such as pultrusion, filament winding, or resin transfer molding exhibit varying levels of complexity, time consumption, and material waste. Advanced manufacturing technologies may increase initial costs but result in higher quality products, which could be economically justified by enhanced performance and longevity.

3. Market Demand and Supply The dynamics of demand and supply in the FRP market can lead to fluctuations in pricing. As industries recognize the advantages of FRP materials, the demand may increase, leading to higher prices if the supply does not keep up. Seasonal trends, economic conditions, and global events can also influence market conditions, thereby affecting FRP rod prices.

frp rod price

4. Application-Specific Requirements Different applications necessitate specific characteristics from FRP rods. For instance, rods intended for use in extreme environments may require additional treatments or materials to enhance their properties, which can increase costs. Furthermore, custom sizes and elongation capabilities might be requested, contributing to a variation in pricing based on these tailored specifications.

5. Geographical Factors The location of production and the proximity to raw material sources can influence pricing as well. Regions rich in natural resources or established manufacturing infrastructures may offer lower production costs, thereby resulting in competitive pricing for FRP rods. Conversely, areas reliant on imports may experience higher costs due to transportation and import tariffs.

6. Regulatory Considerations Compliance with safety and environmental regulations can add to the production costs of FRP rods. Manufacturers must ensure that their products meet industry standards, which may require additional testing, certification, and documentation. Consequently, the need to adhere to these regulations often translates into higher prices for end-users.

The Future of FRP Rod Pricing

The prognosis for FRP rod pricing is expected to evolve alongside technological advancements and a growing emphasis on sustainability. As research and development continue to yield innovative manufacturing techniques that enhance efficiency and reduce waste, the cost of producing FRP rods may decline over time. Furthermore, as industries shift towards more sustainable materials, the demand for eco-friendly FRP options could lead to new pricing structures based on lifecycle assessments and energy consumption during production.

In conclusion, while the prices of FRP rods are influenced by a multitude of factors, the ongoing advancements in material science and manufacturing techniques, along with shifting market demands, are likely to shape the future landscape of this industry. Stakeholders are encouraged to stay informed about these dynamics to make strategic decisions about procurement, production, and investment in FRP technologies. Understanding the interplay of these factors will help businesses effectively navigate the market, ensuring they remain competitive in an ever-evolving economic environment.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

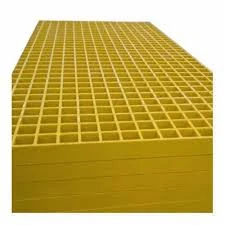

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025