loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Current Trends in FRP Rebar Pricing and Market Analysis

Understanding the Pricing of FRP Rebar in Today's Market

Fiber Reinforced Polymer (FRP) rebar has emerged as a revolutionary material in the construction industry, offering several advantages over traditional steel rebar. Its lightweight nature, high corrosion resistance, and high tensile strength make FRP rebar an appealing choice for various applications, including bridges, tunnels, and buildings. However, the pricing of FRP rebar can vary significantly, influenced by several factors. This article aims to explore the pricing dynamics of FRP rebar, helping stakeholders understand the nuances of the market.

What is FRP Rebar?

FRP rebar is made from a composite of polymer and fibers, typically glass, carbon, or aramid. Unlike steel, which is susceptible to rust and corrosion, FRP rebar maintains excellent durability, especially in environments where conventional materials would degrade over time. This characteristic results in lower maintenance costs and extended service life for structures utilizing FRP rebar. However, one of the critical factors that potential users need to consider is the price of FRP rebar, which can sometimes be higher than that of its steel counterparts.

Factors Influencing the Price of FRP Rebar

1. Raw Material Costs The price of FRP rebar largely depends on the cost of its raw materials. Glass fibers and resin are the primary components, and fluctuations in the prices of these materials can have a direct impact on the cost of production. Global demands and local availability can also influence pricing.

2. Manufacturing Process The production of FRP rebar involves sophisticated manufacturing techniques that can include pultrusion or filament winding. These processes require advanced technology and skilled labor, which can contribute to higher overall costs. Innovations in manufacturing techniques may reduce costs over time, but current prices reflect the complexity involved.

3. Market Demand As the construction industry seeks sustainable and durable materials, the demand for FRP rebar has been on the rise. Projects focusing on infrastructure resilience often prefer FRP rebar due to its unique properties. Increased demand can push prices higher, particularly in regions where traditional materials are in short supply or heavily regulated.

frp rebar price

4. Transportation and Logistics FRP rebar is lightweight and offers logistical advantages, but the cost of transporting these materials can affect final pricing. Geographic location and distance from manufacturing facilities play critical roles. If shipping costs are high, they can significantly impact the final price of FRP rebar delivered to the site.

5. Regulatory Factors Standards and regulations can influence the FRP rebar market significantly. Regions with strict building codes may increase costs due to the need for certification and testing. Compliance with local and international standards adds to the overall pricing landscape.

Comparative Pricing

When comparing FRP rebar prices with traditional steel rebar, it is essential to take a holistic view of total cost implications. While the upfront cost of FRP may be higher than that of steel, the long-term savings in maintenance and replacement should be considered. Projects that anticipate significant exposure to corrosive environments, such as marine or acidic conditions, often find a compelling case for the initial investment in FRP rebar.

Current Trends and Future Outlook

Looking ahead, the FRP rebar market is expected to evolve in response to changes in technology, raw material availability, and environmental considerations. Advances in manufacturing processes that lower production costs could gradually bring FRP pricing more in line with traditional materials. Moreover, as awareness of the benefits of FRP rebar grows, its adoption in mainstream construction could lead to economies of scale that favor price reduction.

Conclusion

Understanding the pricing dynamics of FRP rebar is essential for construction professionals and stakeholders involved in infrastructure projects. While initial costs may be higher compared to traditional steel, the longevity, durability, and reduced lifecycle costs present a convincing argument for its use. As the industry continues to innovate and address challenges related to material costs and manufacturing processes, FRP rebar is poised to become an increasingly viable option for sustainable construction solutions. Ultimately, careful consideration of both upfront and long-term costs will guide decision-making in this evolving market.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

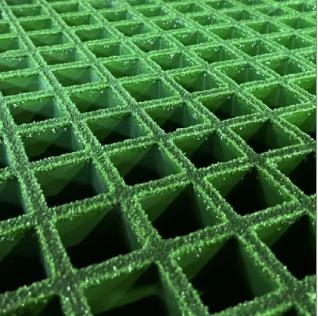

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025