loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Solutions for Pressure Tank Design Using Fiber Reinforced Plastics

Understanding FRP Pressure Tanks Advantages and Applications

Fiber Reinforced Plastic (FRP) pressure tanks have emerged as a favored solution in various industries due to their unique combination of strength, durability, and lightweight characteristics. These tanks are manufactured from a composite material that primarily consists of a polymer matrix reinforced with fibers, such as glass, carbon, or aramid. This innovative construction offers numerous advantages over traditional materials, such as steel or concrete.

One of the primary attributes of FRP pressure tanks is their exceptional resistance to corrosion. Unlike metal tanks, which can deteriorate when exposed to harsh chemicals or environmental conditions, FRP tanks maintain their structural integrity over time. This resistance is critical in industries like water treatment, chemical processing, and wastewater management, where chemical exposure can lead to severe degradation of traditional materials.

Understanding FRP Pressure Tanks Advantages and Applications

Furthermore, FRP pressure tanks offer superior thermal insulation properties. The composite materials used in their construction provide an effective barrier against temperature fluctuations, which is essential in processes requiring precise temperature control. Industries such as food and beverage, pharmaceuticals, and oil and gas can greatly benefit from this aspect, as maintaining specific temperatures can be crucial for product quality and safety.

frp pressure tank

Another noteworthy advantage of FRP pressure tanks is their customization options. Manufacturers can tailor the design, size, and configuration of the tanks to meet specific customer requirements. This flexibility allows businesses to optimize their operations to fit the unique parameters of their processes, enhancing efficiency. Additionally, FRP tanks can be manufactured in various shapes and sizes, allowing for space-saving installations and better integration into existing systems.

However, it is essential to note that while FRP pressure tanks offer numerous advantages, they also come with specific considerations. For instance, the initial investment for FRP tanks can be higher than that for conventional tanks. Nevertheless, the long-term savings associated with reduced maintenance costs, lower energy consumption, and extended lifespan often justify the higher upfront cost.

Furthermore, the manufacturing process of FRP tanks can be complex, requiring skilled labor and specialized equipment to ensure quality and safety. As with any product, it is crucial for businesses to work with reputable manufacturers who adhere to industry standards and regulations to guarantee the safety and reliability of the tanks.

In terms of applications, FRP pressure tanks find use across a wide range of industries. In the water treatment sector, they are commonly employed for the storage and distribution of potable water, as well as in chemical dosing applications. The oil and gas industry utilizes these tanks for the storage of corrosive fluids and chemicals. Additionally, the agricultural sector benefits from FRP tanks for storing fertilizers and other agricultural chemicals due to their resistance to chemical degradation.

In conclusion, FRP pressure tanks represent a significant advancement in storage and pressure vessel technology. Their corrosion resistance, lightweight nature, thermal insulation properties, and customization options make them an attractive choice for various industries. While initial costs may be higher, the long-term benefits, including lower maintenance expenses and increased operational efficiency, make FRP tanks a worthwhile investment. As industries continue to emphasize sustainability and efficiency, the adoption of FRP pressure tanks is likely to grow, further solidifying their role in modern industrial applications.

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025

-

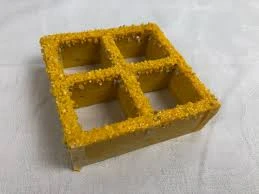

The Strength and Durability of FRP GratingNewsMay.21,2025

-

The Importance of Water Treatment Systems for Clean and Safe WaterNewsMay.21,2025

-

The Advantages of FRP Rebar for Construction ProjectsNewsMay.21,2025

-

Say Goodbye to Hard Water with a Reliable Water SoftenerNewsMay.21,2025

-

Maximize Your Water Storage with a Sectional Water TankNewsMay.21,2025

-

The Power of Filter VesselsNewsMay.19,2025