loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

មករា . 14, 2025 10:15

Back to list

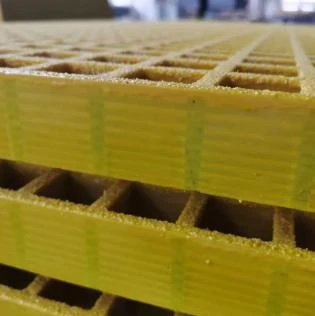

frp micro mesh grating

Galvanised floor grating serves as a practical solution for industrial flooring, merging robust functionality with safety and durability. Over the years, its demand has escalated across various industrial sectors. This specific product is designed to endure challenging environments while providing reliable performance, making it an ideal choice for factory floors, walkways, and platforms.

Galvanised floor grating also scores high on environmental sustainability. Due to its long lifespan and recyclability, it serves as an eco-friendly choice for businesses looking to minimize their carbon footprint. The zinc used in the galvanisation process is non-toxic and ensures the grating can be recycled entirely at the end of its lifecycle. Creating a reliable source of information about these products draws on authoritative insights from industry leaders. According to engineering studies and material experts, the choice of galvanised grating can be a cost-effective investment in the long run. While the upfront cost might be higher compared to non-galvanised options, the longevity and minimal maintenance required make it economically sound. Trustworthiness is woven into the narrative of galvanised floor grating's reputation. Testimonials from industries such as oil and gas, manufacturing, and construction attest to its reliable performance and efficiency. These sectors have seen significant improvements in operational safety and cost savings, as shared in numerous case studies and industry reports. In conclusion, when considering industrial flooring solutions, galvanised floor grating represents an intersection of expertise, durability, and safety. It offers industries a flooring alternative that is not only economically viable but also environmentally sound. By investing in galvanized options, companies ensure they meet the rigorous demands of their industry while safeguarding their workforce and the environment. Choosing galvanised floor grating means opting for proven performance backed by industry trust and authority.

Galvanised floor grating also scores high on environmental sustainability. Due to its long lifespan and recyclability, it serves as an eco-friendly choice for businesses looking to minimize their carbon footprint. The zinc used in the galvanisation process is non-toxic and ensures the grating can be recycled entirely at the end of its lifecycle. Creating a reliable source of information about these products draws on authoritative insights from industry leaders. According to engineering studies and material experts, the choice of galvanised grating can be a cost-effective investment in the long run. While the upfront cost might be higher compared to non-galvanised options, the longevity and minimal maintenance required make it economically sound. Trustworthiness is woven into the narrative of galvanised floor grating's reputation. Testimonials from industries such as oil and gas, manufacturing, and construction attest to its reliable performance and efficiency. These sectors have seen significant improvements in operational safety and cost savings, as shared in numerous case studies and industry reports. In conclusion, when considering industrial flooring solutions, galvanised floor grating represents an intersection of expertise, durability, and safety. It offers industries a flooring alternative that is not only economically viable but also environmentally sound. By investing in galvanized options, companies ensure they meet the rigorous demands of their industry while safeguarding their workforce and the environment. Choosing galvanised floor grating means opting for proven performance backed by industry trust and authority.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025