loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

មករា . 29, 2025 02:29

Back to list

frp vessel for water treatment

FRP guardrails represent a modern solution that combines durability with practicality, fitting perfectly into the growing demands of various industries requiring safe and reliable barrier systems. These guardrails are composed of Fiber Reinforced Polymer, a composite material well-known for its strength and versatility, offering a compelling alternative to traditional materials such as steel or wood.

From a safety perspective, FRP guardrails are non-conductive, which is critical in facilities where electrical safety is a priority. This feature reduces the risk of electrical hazards, offering an added layer of safety in power plants or electrical substations. Additionally, FRP does not propagate flames, making it a safer choice concerning fire hazards compared to traditional materials like wood or certain metals. The development and production of FRP guardrails also reflect an authoritative commitment to sustainability. As industries evolve towards greener practices, the use of recyclable materials such as FRP complies with eco-friendly construction principles. With an increasing emphasis on reducing carbon footprints, choosing materials that support sustainable building practices is crucial, and FRP guardrails contribute significantly to this goal. The credibility and reliability of FRP guardrails are underscored by their widespread adoption in various high-stakes sectors. Many industry experts recognize FRP as a leading material technology that meets rigorous safety and compliance standards. Field tests and historical performance data continue to affirm the superiority of FRP guardrails in conditions where conventional materials falter. As such, purchasing decision-makers prioritize them for their proven performance and alignment with evolving regulatory landscapes. For industries looking to enhance their safety protocols without compromising on quality or aesthetics, FRP guardrails offer a well-rounded solution. Their unique blend of strength, adaptability, and sustainability not only advances operational safety but also supports broader industry trends towards more efficient and eco-conscious practices. Investing in FRP guardrails isn't just a decision for today; it's a strategic move for future-proofing safety infrastructure in a rapidly changing world.

From a safety perspective, FRP guardrails are non-conductive, which is critical in facilities where electrical safety is a priority. This feature reduces the risk of electrical hazards, offering an added layer of safety in power plants or electrical substations. Additionally, FRP does not propagate flames, making it a safer choice concerning fire hazards compared to traditional materials like wood or certain metals. The development and production of FRP guardrails also reflect an authoritative commitment to sustainability. As industries evolve towards greener practices, the use of recyclable materials such as FRP complies with eco-friendly construction principles. With an increasing emphasis on reducing carbon footprints, choosing materials that support sustainable building practices is crucial, and FRP guardrails contribute significantly to this goal. The credibility and reliability of FRP guardrails are underscored by their widespread adoption in various high-stakes sectors. Many industry experts recognize FRP as a leading material technology that meets rigorous safety and compliance standards. Field tests and historical performance data continue to affirm the superiority of FRP guardrails in conditions where conventional materials falter. As such, purchasing decision-makers prioritize them for their proven performance and alignment with evolving regulatory landscapes. For industries looking to enhance their safety protocols without compromising on quality or aesthetics, FRP guardrails offer a well-rounded solution. Their unique blend of strength, adaptability, and sustainability not only advances operational safety but also supports broader industry trends towards more efficient and eco-conscious practices. Investing in FRP guardrails isn't just a decision for today; it's a strategic move for future-proofing safety infrastructure in a rapidly changing world.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

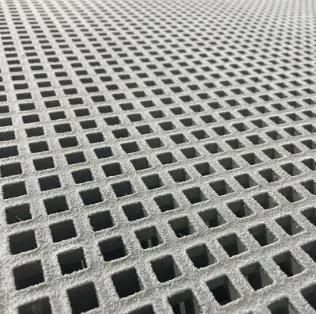

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025