loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Filter Vessel Design and Applications for Efficient Water Treatment Solutions

Understanding FRP Filter Vessels An Essential Component in Water Treatment

In the realm of water treatment and filtration, the materials used in system components play a crucial role in the effectiveness, longevity, and overall performance of these systems. One such material that has gained significant attention in recent years is Fiberglass Reinforced Plastic (FRP). FRP filter vessels are rapidly becoming a preferred choice in various industries due to their unique qualities and advantages.

What is FRP?

Fiberglass Reinforced Plastic (FRP) is a composite material made of a polymer matrix reinforced with glass fibers. The combination of these materials results in a lightweight yet extremely strong product. FRP can withstand harsh environmental conditions, making it ideal for use in settings that involve exposure to corrosive substances, high pressures, or extreme temperatures.

Applications of FRP Filter Vessels

FRP filter vessels are primarily used in water treatment applications, including municipal water facilities, industrial water processing, and residential filtration systems. They are essential for removing contaminants and impurities from water, thereby ensuring safety and compliance with health regulations. Here are some of the most common applications

1. Water Filtration FRP filter vessels are utilized for both drinking water and wastewater treatment, effectively removing sediment, bacteria, and other undesired substances.

2. Chemical Processing Many industries rely on FRP filter vessels to handle aggressive chemicals. The corrosion resistance of FRP ensures that the vessel will not degrade over time, which could lead to leaks and system failures.

3. Swimming Pool Filtration FRP vessels are also used for the filtration of swimming pool water, providing a durable and effective means of keeping water clean and safe for recreational use.

Advantages of FRP Filter Vessels

frp filter vessel

1. Corrosion Resistance One of the most significant benefits of FRP filter vessels is their resistance to corrosion. Unlike traditional metal tanks, FRP does not rust or corrode when exposed to water and chemicals, prolonging the lifespan of the equipment.

2. Lightweight and Durable FRP filter vessels are much lighter than steel or concrete alternatives. This makes handling, transportation, and installation easier, ultimately reducing overall costs.

3. Design Flexibility The manufacturing process of FRP allows for a variety of shapes and sizes, enabling customization to meet specific operational requirements. This flexibility helps in optimizing space and efficiency.

4. Thermal Insulation FRP has excellent insulating properties, reducing the risk of temperature fluctuations that could affect the filtration process.

5. Cost-Effective Although the initial investment in FRP filter vessels can be higher than traditional materials, the long-term savings due to reduced maintenance costs and longer operational life make them a financially viable option.

Maintenance of FRP Filter Vessels

While FRP filter vessels are designed to be low-maintenance, some practices can enhance their lifespan. Regular inspections for any signs of wear, along with scheduled cleaning to remove any buildup of contaminants on the filter media, are critical. Furthermore, ensuring that the connections and fittings are securely tightened can prevent leaks and maintain system integrity.

Conclusion

In conclusion, FRP filter vessels are an innovative solution for modern water treatment systems. Their unique properties, including corrosion resistance, lightweight nature, and design flexibility, make them an ideal choice for a variety of applications ranging from municipal water supply to industrial processes. As the demand for clean and reliable water sources continues to grow, the importance of effective filtration systems, particularly those utilizing advanced materials like FRP, will undoubtedly increase. Investing in FRP filter vessels not only ensures efficient filtration but also contributes to sustainable practices within the water treatment industry.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

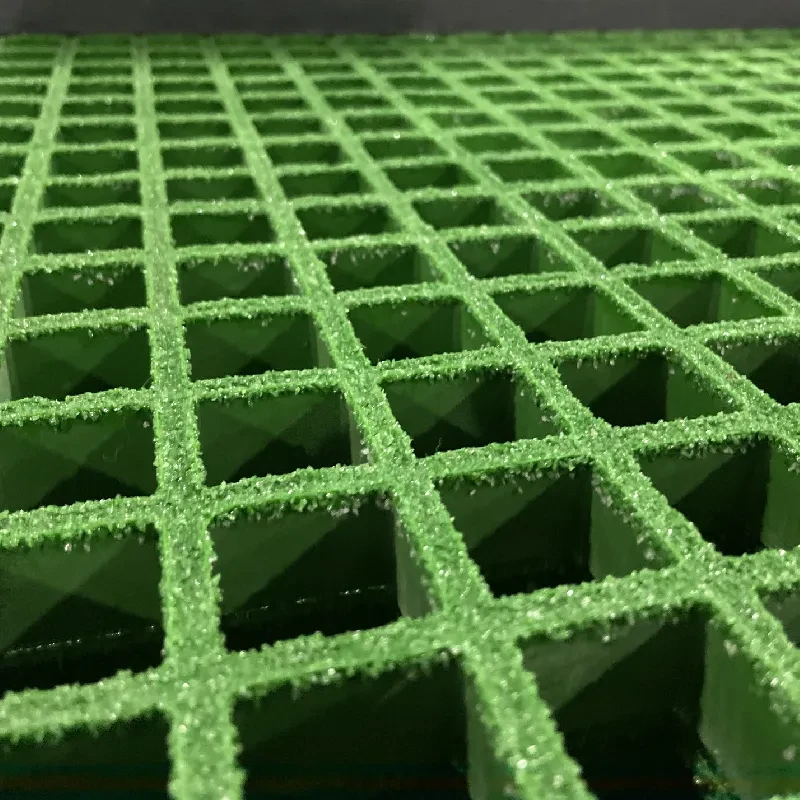

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025