loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

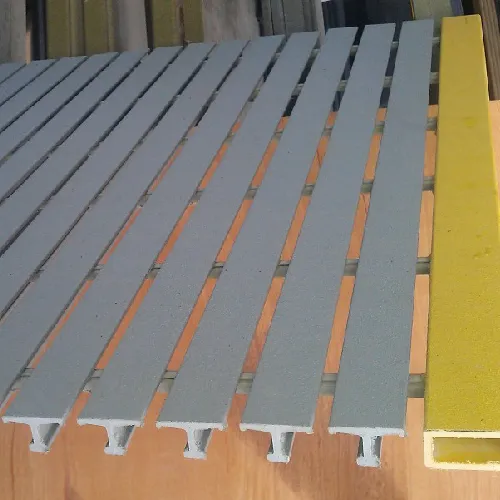

frp c channel

Understanding FRP C Channel A Modern Solution for Various Applications

In recent years, the construction and manufacturing industries have witnessed significant advancements with the introduction of innovative materials. One such material making waves is Fiber Reinforced Polymer (FRP), particularly in the form of C channels. The FRP C channel has become increasingly popular due to its unique properties that offer numerous benefits over traditional materials such as steel and aluminum.

What is FRP?

FRP is a composite material made by combining a polymer matrix with fibrous reinforcement. The most common type of reinforcement used in FRP is glass fibers, though carbon and aramid fibers can also be employed for specific applications. This combination results in a material that is incredibly strong and lightweight, with excellent corrosion resistance, making it ideal for a wide range of applications.

Characteristics of FRP C Channels

FRP C channels are formed in a 'C' shape, similar to traditional metal channels, but with the enhanced properties of FRP. Some key characteristics of FRP C channels include

1. Lightweight One of the most significant advantages of FRP C channels is their lightweight nature. They are typically much lighter than their steel counterparts, reducing the overall weight of structures and easing installation procedures.

2. Corrosion Resistance Unlike steel, FRP does not rust or corrode when exposed to harsh environments, such as saltwater or chemicals. This attribute is particularly beneficial for applications in marine, chemical, or wastewater treatment sectors.

3. High Strength-to-Weight Ratio FRP C channels possess an impressive strength-to-weight ratio, making them suitable for both structural and non-structural applications. Their strength can often rival that of traditional materials while maintaining a significantly reduced weight.

4. Durability FRP materials demonstrate excellent durability, providing long-term performance with minimal maintenance. This reliability translates into cost savings over the lifespan of the material, as replacements and repairs can be significantly reduced.

frp c channel

5. Customization FRP C channels can be manufactured to meet specific design requirements, including varying thicknesses, lengths, and specifications. This flexibility allows engineers and designers to tailor the channels to suit particular project needs.

Applications of FRP C Channels

The versatility of FRP C channels opens the door to a myriad of applications across various industries. Below are some of the main areas where FRP C channels are making an impact

1. Construction In the construction industry, FRP C channels are becoming increasingly utilized as structural supports, framing elements, and reinforcements. Their lightweight nature makes them easier to handle and install, while their strength ensures structural integrity.

2. Transportation FRP C channels find applications in the manufacturing of lightweight vehicles, rail systems, and bridges. Their ability to withstand environmental stresses without corroding makes them ideal for applications exposed to harsh conditions.

3. Marine Industry In the marine sector, where corrosion is a significant concern, FRP C channels are increasingly used for constructing docks, piers, and other structures. Their resilience against saltwater makes them a sustainable choice for maritime applications.

4. Electrical and Telecommunications FRP C channels are also utilized for mounting electrical and telecommunications equipment, benefiting from their non-conductive properties and lightweight nature.

Conclusion

The adoption of FRP C channels represents a significant shift towards more sustainable and efficient building practices. With their unique properties combining strength, lightweight design, and corrosion resistance, they offer innovative solutions that traditional materials cannot match. As industries continue to seek alternatives that provide long-term value and sustainability, the role of FRP C channels is poised to grow in importance, marking a new era in construction and manufacturing practices. Thus, embracing this modern material can lead to enhanced performance, durability, and efficiency in various projects, ultimately benefiting both businesses and the environment.

-

The Expansive Industrial Reign of FRP Pressure VesselsNewsAug.22,2025

-

Manufacturing Premium FRP Square Pipes for Global Wholesale ExcellenceNewsAug.22,2025

-

Strategic Applications for FRP Grating SolutionsNewsAug.22,2025

-

Material Science Forging GRP Water Tank LongevityNewsAug.22,2025

-

The Engineered Excellence: Material Science Behind FRP Railing SystemsNewsAug.22,2025

-

How Digital Pultrusion Revolutionizes FRP Profile WholesalingNewsAug.22,2025

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025