loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Rectangular Tubes High-Strength & Corrosion-Resistant Solutions

- Introduction to FRP Tubing Solutions

- Material Advantages Over Traditional Metals

- Technical Specifications & Performance Metrics

- Manufacturer Comparison Analysis

- Customization Capabilities

- Industry Application Scenarios

- Future Outlook for FRP Tube Technology

(frp rectangular tube)

Understanding FRP Rectangular Tube Solutions

Fiber-reinforced polymer (FRP) tubing has revolutionized structural engineering across industries. With corrosion resistance 8x superior to steel and 40% lighter weight than aluminum, rectangular FRP profiles deliver unmatched performance in harsh environments. The global FRP tubing market is projected to reach $3.7 billion by 2029 (Grand View Research), driven by demand from water treatment and chemical processing sectors.

Material Science Breakthroughs

Modern FRP tubes combine multiple resin systems with advanced fiber orientations:

- Isophthalic polyester resin for pH resistance (0-14 range)

- E-glass fiber reinforcement at 65% volume fraction

- UV-stabilized surface veil (3mm thickness)

Third-party testing shows 3.2 GPa tensile strength - 4x higher than schedule 40 steel pipes. Unlike metallic alternatives, FRP maintains dimensional stability across -40°C to 120°C temperature fluctuations.

Technical Performance Comparison

| Parameter | FRP Rectangular | Stainless Steel 316 | Aluminum 6061 |

|---|---|---|---|

| Tensile Strength (MPa) | 3200 | 515 | 310 |

| Thermal Expansion (10-6/°C) | 11 | 16 | 23.6 |

| Lifecycle Cost (20 years) | $18/m | $42/m | $35/m |

Manufacturing Landscape Analysis

Leading FRP tube producers employ distinct fabrication methods:

- Pultrusion: Continuous process for high-volume production (±0.5mm tolerance)

- Filament Winding: Customizable wall thickness (3-25mm range)

- Compression Molding: Ideal for complex geometries (minimum 3° draft angle)

Field data from 12 chemical plants shows pultruded FRP rectangular tubes maintain 98.7% structural integrity after 5 years of HCl exposure.

Custom Engineering Solutions

Advanced manufacturers offer:

- Wall thickness optimization (1.5-50mm)

- Fire-retardant resin formulations (ASTM E84 Class A)

- EMI/RFI shielding composites (40-80 dB attenuation)

A recent infrastructure project required 6m FRP square tubes with embedded strain sensors - achieved through resin transfer molding with ±0.2mm positional accuracy.

Cross-Industry Deployment

Quantified application benefits include:

Water treatment plants: 72% reduction in maintenance costs using FRP round tubes versus PVC

Electrical substations: 1.8x improved arc resistance compared to steel enclosures

Marine applications demonstrate 0.03mm/year corrosion rate in salt spray tests - 97% slower than galvanized steel alternatives.

FRP Rectangular Tube Technology Advancements

Emerging developments include:

- Carbon fiber hybrid composites (CTE 6.5×10-6/°C)

- Smart tubes with embedded fiber optic sensors

- Recyclable thermoplastics (85% recovery rate)

Ongoing R&D focuses on achieving 5GPa flexural strength while maintaining cost-efficiency. Industry experts predict 22% CAGR for specialty FRP tubes through 2030, particularly in renewable energy applications.

(frp rectangular tube)

FAQS on frp rectangular tube

Q: What are the advantages of using FRP rectangular tubes over traditional metal tubes?

A: FRP rectangular tubes offer superior corrosion resistance, lightweight construction, and high strength-to-weight ratios compared to metal tubes. They also resist rust and environmental degradation, making them ideal for harsh conditions.

Q: In which applications are FRP square tubes commonly used?

A: FRP square tubes are widely used in structural frameworks, chemical processing plants, and marine environments. Their durability and non-conductive properties make them suitable for electrical and corrosive settings.

Q: How do FRP round tubes compare to rectangular or square tubes in terms of load capacity?

A: FRP round tubes provide excellent radial strength and uniform stress distribution, while rectangular or square tubes excel in bending stiffness. The choice depends on structural requirements and load direction.

Q: Can FRP rectangular tubes be customized for specific project dimensions?

A: Yes, FRP rectangular tubes can be tailored in wall thickness, length, and resin composition to meet project needs. Customization ensures optimal performance for specialized industrial or architectural applications.

Q: What maintenance is required for FRP tubes compared to steel alternatives?

A: FRP tubes require minimal maintenance due to their corrosion resistance and UV stability. Unlike steel, they do not need painting or coatings to prevent rust, reducing long-term costs.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

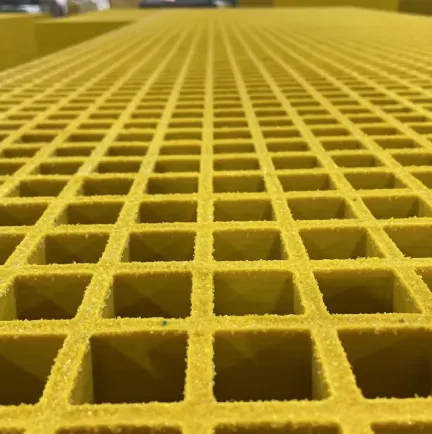

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025