loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Grating Suppliers: Quality Micro Mesh & Standard Panels

The Evolving Landscape of FRP Grating Solutions for Industrial Applications

The demand for advanced composite materials in industrial infrastructure continues to accelerate, with Fiberglass Reinforced Plastic (FRP) gratings leading the charge. As industries seek more durable, safer, and cost-effective alternatives to traditional metallic gratings, the role of reliable frp grating suppliers becomes paramount. This article delves into the critical aspects of FRP grating, from its sophisticated manufacturing processes and inherent technical advantages to its diverse application scenarios. We also explore key considerations for procurement, including product specifications, supplier comparison, and the immense value of custom solutions, all designed to inform B2B decision-makers and technical personnel. Understanding these elements is crucial for optimizing operational safety, longevity, and overall project efficiency in demanding industrial environments.

Advanced Manufacturing: The Core of FRP Grating Excellence

The quality and performance of FRP grating are intrinsically linked to its manufacturing process. Primarily, two methods dominate the production of high-performance FRP gratings: molded and pultruded. Molded FRP gratings are manufactured by laying continuous glass fibers in a pre-designed mold and impregnating them with a liquid resin (e.g., Isophthalic Polyester, Vinyl Ester, Phenolic). This entire structure is then cured under heat, resulting in a monolithic, corrosion-resistant, and inherently bi-directional strength panel. This casting process ensures consistent quality and excellent load distribution. Pultruded gratings, on the other hand, are formed by pulling continuous glass fibers and resin through a heated die, creating individual load-bearing bars. These bars are then mechanically joined to form a complete panel. Each method offers distinct advantages in terms of strength-to-weight ratio, load capacity, and design flexibility.

Figure 1: Illustration of a typical FRP grating manufacturing facility, highlighting process control.

Rigorous quality control and adherence to international inspection standards such as ISO 9001:2015 and ANSI/NEMA FG 1 are critical at every stage. This ensures products like the Anti Slip and Factory Outlet Standard Mesh FRP GRP Grating meet stringent performance benchmarks for deflection, slip resistance, and chemical compatibility. The typical service life of high-quality FRP grating can extend beyond 20 years, even in aggressive environments, far surpassing the longevity of traditional materials when exposed to corrosive elements. This exceptional durability translates directly into reduced maintenance costs and fewer operational disruptions, making FRP a strategic investment for industries such as petrochemical, metallurgy, mining, marine, power generation, and water/wastewater treatment.

Technical Advantages and Application Scenarios

The intrinsic properties of FRP gratings offer a compelling array of technical advantages over steel or aluminum. Foremost among these is superior corrosion resistance to a wide range of chemicals, acids, and alkalis, which is vital in chemical processing plants and wastewater treatment facilities. Unlike metals, FRP does not rust, pit, or degrade, ensuring consistent structural integrity. Furthermore, FRP is inherently lightweight, typically one-third the weight of steel, which significantly simplifies installation, reduces labor costs, and lessens the load on supporting structures. Its non-conductive nature provides excellent electrical insulation, making it ideal for applications near electrical equipment, while its non-magnetic properties are beneficial in sensitive environments like MRI rooms.

Figure 2: An example of FRP grating in a corrosive industrial walkway.

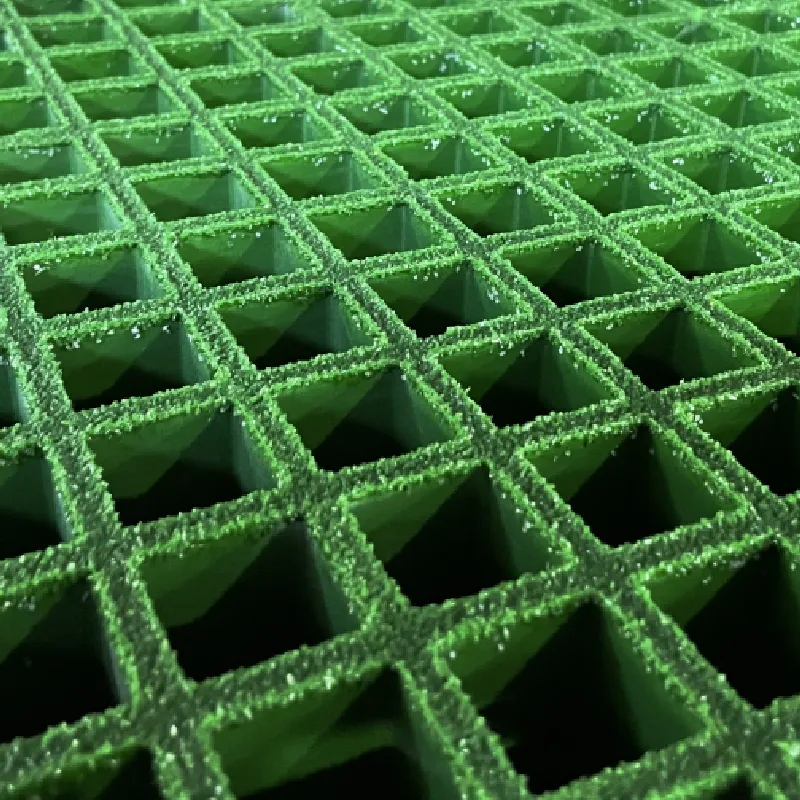

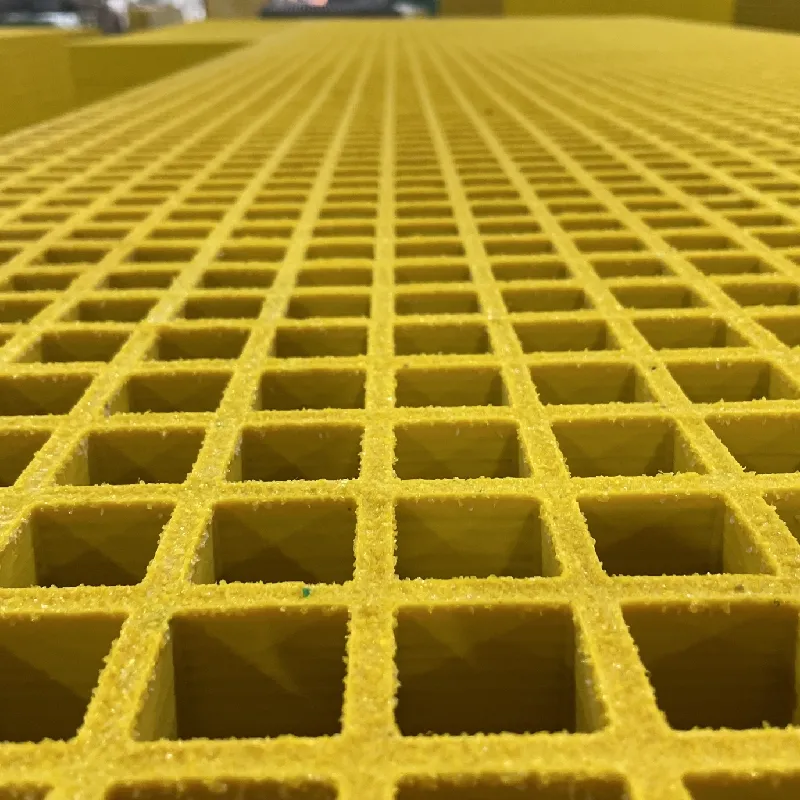

FRP also boasts excellent anti-slip properties, often featuring grit surfaces or concave designs, significantly enhancing worker safety on platforms, walkways, and stair treads. This is particularly crucial in wet or oily industrial settings. The specific application of frp micro mesh grating, for instance, provides enhanced safety by preventing small objects from falling through and offering a larger contact area for foot traffic, making it suitable for high-traffic pedestrian zones or areas where small tools might be dropped. In terms of sustainability, the extended lifespan of FRP reduces the need for frequent replacements, contributing to lower material consumption and waste over time. Its thermal insulating properties can also contribute to energy efficiency in certain applications.

Choosing the Right FRP Grating Suppliers: A Comparative Analysis

Selecting the optimal frp grating suppliers is a critical decision that impacts project success, safety, and long-term cost of ownership. Beyond initial pricing, factors such as material quality, manufacturing consistency, adherence to international standards, and the breadth of customization options are paramount. Reputable suppliers will provide detailed technical data, including deflection rates under specified loads, chemical resistance charts for various resin systems (e.g., Orthophthalic, Isophthalic, Vinyl Ester, Phenolic), and fire rating compliance (e.g., ASTM E-84). They should also demonstrate a proven track record, evident through industry certifications and successful project case studies.

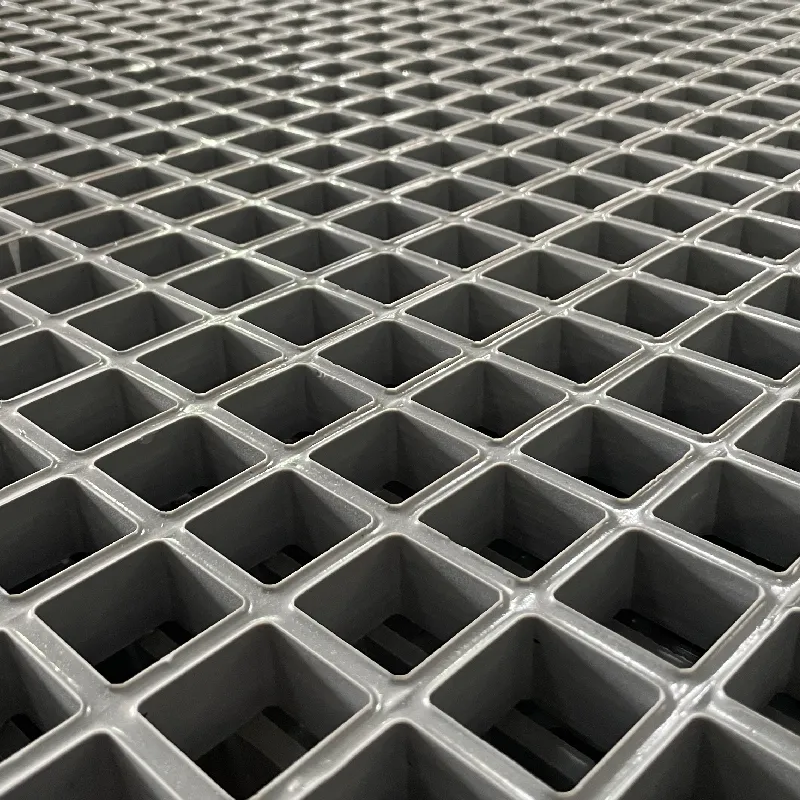

Figure 3: A diverse range of FRP grating products, showcasing different mesh sizes and colors.

Below is a comparative table highlighting key parameters often considered when evaluating Anti Slip and Factory Outlet Standard Mesh FRP GRP Grating from various frp grating suppliers. This data helps technical teams and procurement managers make informed decisions based on specific project requirements and performance expectations.

| Parameter | Unit | Molded FRP Grating | Pultruded FRP Grating |

|---|---|---|---|

| Resin Options | - | Ortho, Iso, Vinyl Ester, Phenolic | Iso, Vinyl Ester, Phenolic |

| Standard Panel Size | mm / ft | 1220x3660 / 4x12, 915x3050 / 3x10 | Custom lengths, Standard widths (e.g., 610mm / 2ft) |

| Thickness Range | mm / inch | 13 to 75 / 0.5 to 3 | 25 to 100 / 1 to 4 |

| Typical Mesh Size | mm / inch | 38x38, 50x50 / 1.5x1.5, 2x2 | Standard 152x152, 203x203 / 6x6, 8x8 on centers |

| Weight (38mm/1.5" thick) | kg/m² / lbs/ft² | ~19.5 / ~4.0 | ~15.0 / ~3.1 (approx. for comparable load) |

| Ultimate Tensile Strength | MPa / psi | ~200-300 / ~29000-43500 | ~350-500 / ~50000-72500 (longitudinal) |

| Fire Rating | ASTM E-84 | Class 1 (Flame Spread ≤ 25) | Class 1 (Flame Spread ≤ 25) |

Customization is a significant advantage when working with proficient frp grating suppliers. Tailored solutions can include specific resin formulations for extreme chemical resistance, unique panel sizes to minimize waste and cutting on-site, diverse color options for safety coding, and specialized anti-slip surfaces. This bespoke approach ensures that the grating system precisely meets the demanding operational and safety requirements of a specific facility or project, delivering optimal performance and cost-effectiveness.

Trust and Support: FAQs, Delivery, and Warranty

Building trust with B2B clients involves transparent communication, robust product support, and clear commitments. Reputable frp grating suppliers prioritize these aspects, offering comprehensive pre-sales consultation and post-sales support.

Frequently Asked Questions (FAQs)

- Q: What is the difference between FRP and GRP?

A: Functionally, FRP (Fiber Reinforced Polymer) is a broader term, and GRP (Glass Reinforced Plastic) is a specific type of FRP where glass fibers are the reinforcement. In the context of grating, the terms are often used interchangeably to refer to fiberglass grating. - Q: Can FRP grating be used outdoors?

A: Absolutely. FRP gratings are inherently UV stabilized and resistant to environmental degradation, making them ideal for outdoor applications like rooftops, bridge walkways, and marine environments. - Q: How do I cut FRP grating?

A: FRP grating can be cut using standard power tools with appropriate cutting blades (e.g., diamond-tipped or carbide grit blades). Always ensure proper ventilation and personal protective equipment (PPE) like dust masks and safety glasses due to fiberglass dust. - Q: Is FRP grating slip-resistant?

A: Yes, most quality FRP gratings, including the Anti Slip and Factory Outlet Standard Mesh FRP GRP Grating, come with integral grit tops or concave profiles to provide excellent slip resistance, even in wet or oily conditions, far exceeding OSHA standards. - Q: What is frp micro mesh grating used for?

A: FRP micro mesh grating features a smaller opening size, typically 19x19mm or 25x25mm (0.75x0.75 inch or 1x1 inch). This design is ideal for applications requiring enhanced safety against small object fall-through, comfortable pedestrian walkways (especially for high heels or wheeled carts), and areas needing improved air circulation with minimal debris passage.

For delivery, lead times can vary based on product customization and order volume. Standard stock items typically ship within 1-2 weeks, while custom orders may require 3-6 weeks, depending on complexity. Reliable frp grating suppliers will provide clear estimates and communicate any potential delays promptly. Regarding quality assurance, most reputable manufacturers offer a warranty period, typically ranging from 5 to 10 years, covering manufacturing defects and material integrity under normal operating conditions. This commitment underscores the confidence in their product's durability and performance. Comprehensive customer support, from initial design consultation to post-installation queries, further solidifies the partnership between supplier and client, ensuring long-term satisfaction.

Conclusion: The Strategic Imperative of FRP Grating

The adoption of FRP grating, exemplified by products like the Anti Slip and Factory Outlet Standard Mesh FRP GRP Grating, represents a strategic shift in industrial infrastructure development. Its unparalleled resistance to corrosion, high strength-to-weight ratio, electrical non-conductivity, and superior safety features position it as an indispensable material for demanding environments. Partnering with experienced frp grating suppliers who emphasize quality manufacturing, offer diverse product lines, and provide robust technical and customer support is crucial for realizing the full benefits of this advanced composite. As industries continue to prioritize operational efficiency, worker safety, and environmental responsibility, FRP grating solutions will play an increasingly vital role in achieving these objectives.

References:

- Compositesworld. "FRP Grating Market Trends and Forecasts."

- American Society for Testing and Materials (ASTM) Standards for Fiberglass Reinforced Plastics.

- International Organization for Standardization (ISO) 9001:2015 Guidelines.

- National Electrical Manufacturers Association (NEMA) FG 1: Fiberglass Grating Manual.

- Occupational Safety and Health Administration (OSHA) Walking/Working Surfaces Standards.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025