loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Fiber-Reinforced Plastic Grating Applications and Benefits for Various Industries

The Advantages of Fibre Reinforced Plastic Grating

In recent years, the construction and manufacturing industries have increasingly turned to advanced materials that combine performance with sustainability. Among these materials, Fibre Reinforced Plastic (FRP) grating has emerged as a groundbreaking solution that offers numerous advantages over traditional options like steel and wood. This article explores what FRP grating is, its benefits, and its applications, highlighting why it's become a preferred choice for many projects.

What is Fibre Reinforced Plastic Grating?

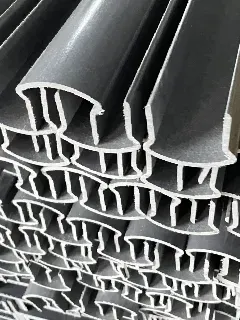

Fibre Reinforced Plastic grating is a high-performance composite material made by embedding reinforcing fibres, typically glass or carbon, into a plastic matrix. This combination provides exceptional strength-to-weight ratios, making FRP grating an efficient alternative to heavier materials. The manufacturing process involves the pultrusion method, where the fibres and resin are drawn through a heated die, creating a continuous and uniform section of material that can be molded into various shapes and sizes.

Lightweight Yet Durable

One of the standout features of FRP grating is its lightweight nature. Weighing significantly less than steel or concrete, it allows for easier handling and installation, reducing labor costs and improving overall efficiency. In environments where weight restrictions are critical, such as on old structures or marine platforms, FRP grating's lightweight properties play a crucial role. Despite its lightness, FRP grating boasts impressive load-bearing capabilities, making it suitable for a wide range of applications.

Corrosion Resistance

Corrosion is a major concern in many industrial environments, particularly those exposed to harsh chemicals or saline conditions. FRP grating is inherently resistant to corrosion, which significantly extends its lifespan compared to steel, which can rust and weaken over time. As a result, FRP grating is an ideal choice for applications in wastewater treatment plants, chemical processing facilities, and coastal structures where corrosive exposure is prevalent. This durability leads to lower maintenance costs and less frequent replacements, providing long-term economic benefits.

fibre reinforced plastic grating

Safety Features

Safety is another critical aspect of any construction material, and FRP grating excels in this regard. It can be manufactured with anti-slip surfaces, making it a safe choice for walkways, platforms, and other walking surfaces. This feature is particularly important in industrial settings where spills may occur, helping to minimize slip and fall accidents. Furthermore, FRP grating is non-conductive, making it a suitable option for electrical installations or environments where electrical hazards are present.

Environmental Benefits

In an era where sustainability is crucial, FRP grating offers significant environmental advantages. The manufacturing process of FRP often generates less waste and can incorporate recycled materials. Being lightweight also means that transportation emissions can be minimized during shipping. Moreover, the longevity and corrosion resistance of FRP grating reduce the need for frequent replacements, thus conserving resources and reducing the overall carbon footprint of construction projects.

Versatile Applications

FRP grating finds applications across a wide range of industries. It is utilized in commercial buildings for walkways and platforms, in water treatment plants for walkways and covers, and in oil and gas industries for safe access to equipment. Additionally, FRP grating can be customized in various colors and sizes, allowing it to cater to specific design requirements.

Conclusion

Fibre Reinforced Plastic grating represents a significant advancement in material science, combining strength, durability, safety, and environmental benefits. As industries continue to seek innovative solutions to meet modern challenges, FRP grating stands out as a versatile and sustainable choice. Its ability to perform excellently under demanding conditions while minimizing environmental impact makes it a compelling option for present and future construction projects. As awareness of its advantages grows, we can expect to see FRP grating become even more prevalent in various applications around the world.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025