loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

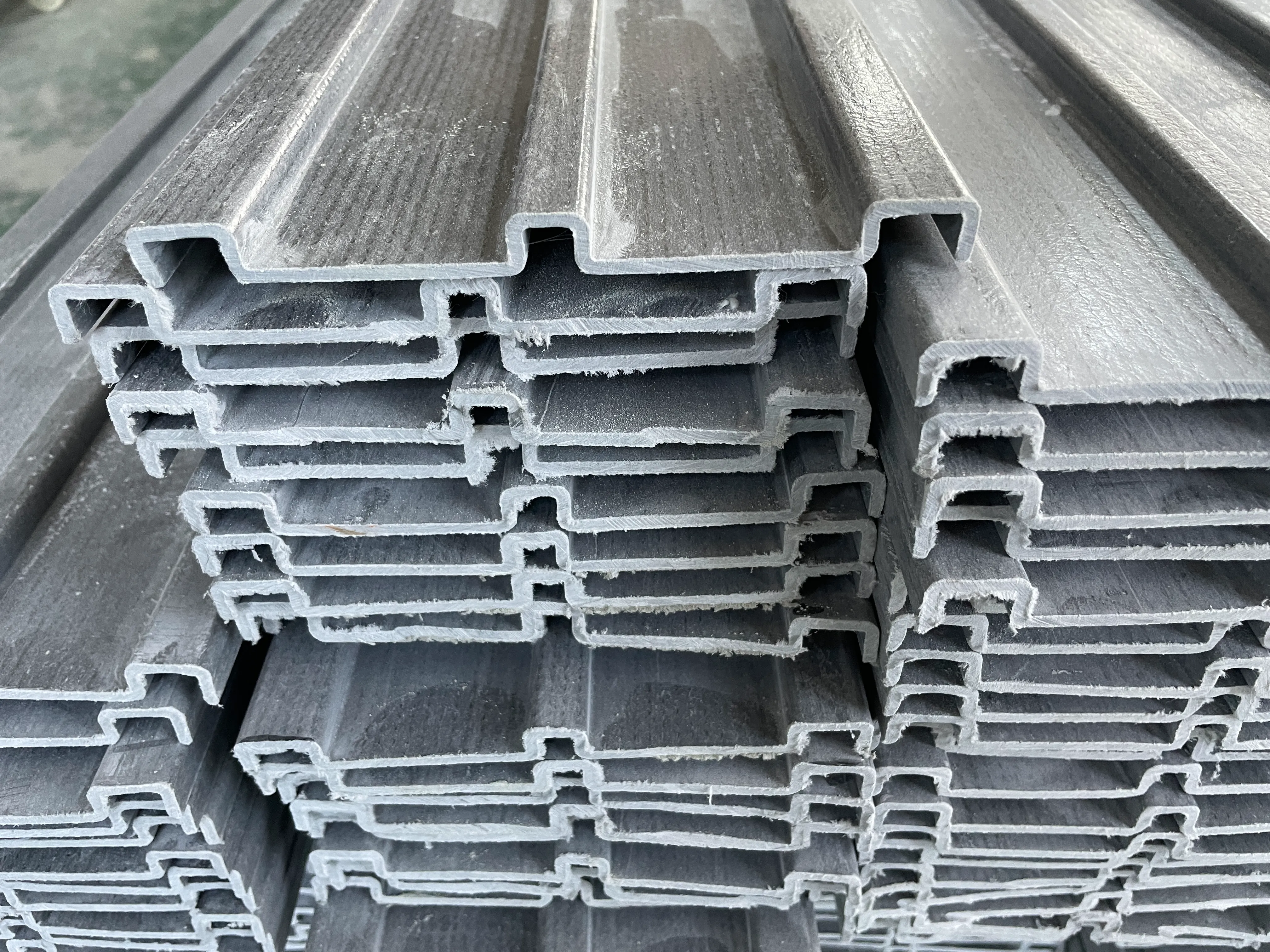

fibreglass reinforced plastic grating

Understanding Fiberglass Reinforced Plastic Grating A Comprehensive Overview

Fiberglass Reinforced Plastic (FRP) grating has become a favored choice in various industrial and commercial applications due to its unique properties and advantages over traditional materials. As the demand for lightweight yet durable construction materials grows, FRP grating stands out for its versatility and performance.

What is FRP Grating?

FRP grating is a composite material made from a mixture of fiberglass and resin, typically polyester or vinyl ester. The process involves combining glass fibers with resin to create a strong, lightweight, and corrosion-resistant material. This innovative design allows FRP grating to withstand harsh environments, making it an ideal choice for industries such as oil and gas, chemical processing, water treatment, and food and beverage production.

Key Benefits of FRP Grating

1. Corrosion Resistance One of the most significant advantages of FRP grating is its exceptional resistance to corrosion. Unlike metal grating, which can rust and degrade when exposed to moisture, chemicals, and salts, FRP grating maintains its structural integrity even in the most demanding environments. This property is particularly beneficial in industries that handle corrosive substances.

2. Lightweight FRP grating is significantly lighter than traditional materials like steel or aluminum. This lightweight nature simplifies handling, installation, and transportation, reducing labor costs and improving overall project efficiency. The ease of installation also leads to decreased downtime in industrial settings.

3. High Strength-to-Weight Ratio Despite its lightweight composition, FRP grating boasts a high strength-to-weight ratio, making it incredibly durable. It can support heavy loads without bending or breaking, ensuring safety and reliability in industrial applications.

4. Non-Conductive FRP grating is non-conductive, which is a vital feature for applications in areas where electrical hazards exist. This property enhances workplace safety by minimizing the risk of electrical shock and ensuring compliance with safety regulations.

5. Slip Resistance Many FRP grating products come with slip-resistant surfaces, which are crucial in minimizing accidents in wet or oily environments. The textured surface offers excellent traction, reducing the likelihood of slips and falls, which is especially important in industrial and outdoor settings.

fibreglass reinforced plastic grating

6. Customizability FRP grating can be manufactured in various shapes, sizes, and colors to meet specific project requirements. Whether you need grating for walkways, platforms, or drainage covers, the ability to customize FRP products allows for tailored solutions that fit the unique demands of each application.

Applications of FRP Grating

The versatility of FRP grating lends itself to a wide range of applications across different industries. Common uses include

- Walkways and Platforms FRP grating is often used for pedestrian walkways and worker platforms in industries such as oil and gas, water treatment, and mining, where corrosion resistance and slip safety are paramount.

- Mezzanines and Catwalks In warehouses and industrial settings, FRP can be utilized for building mezzanine floors and catwalks, enabling safe access to elevated areas.

- Trench Covers FRP grating is an excellent choice for trench covers, providing easy access for maintenance while ensuring safety and durability.

- Chemical Processing Due to its resistance to corrosive materials, FRP grating is widely employed in chemical plants for platforms, stairs, and machinery bases.

- Food Processing The non-porous and easy-to-clean nature of FRP makes it suitable for use in food and beverage industries, where hygiene and cleanliness are critical.

Conclusion

Fiberglass Reinforced Plastic grating offers a multitude of benefits that cater to the evolving needs of modern industries. Its combination of corrosion resistance, lightweight properties, high strength, and safety features render it an ideal material for a vast array of applications. As industries continue to seek sustainable and durable solutions, FRP grating will likely play an increasingly prominent role in future projects. Whether you're in construction, manufacturing, or chemical processing, considering FRP grating for your next application could lead to significant long-term benefits, from cost savings to enhanced safety standards.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025