loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

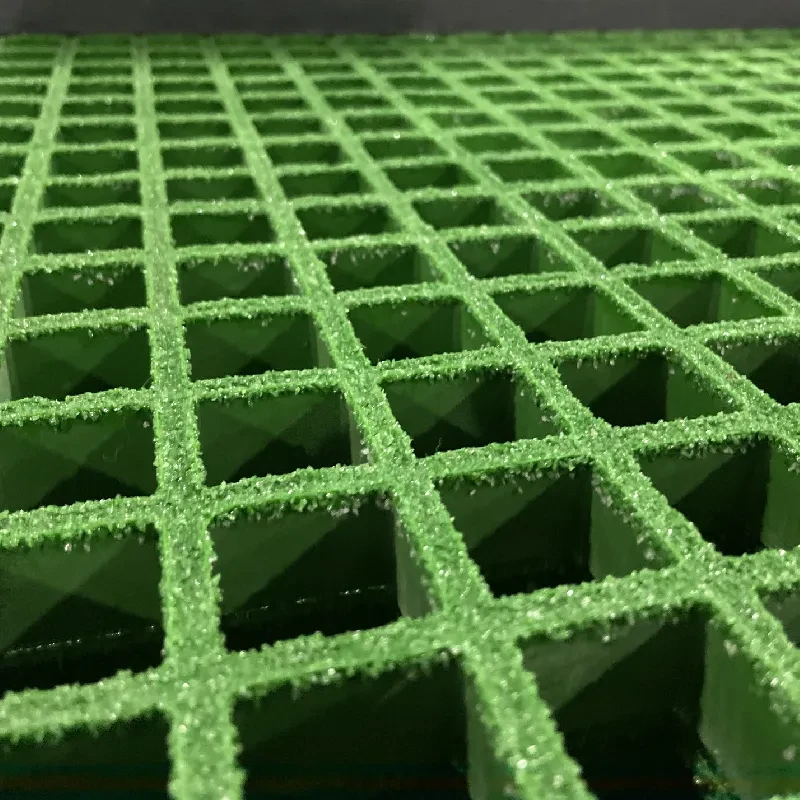

fiberglass reinforced plastic grating

Fiberglass Reinforced Plastic Grating A Comprehensive Overview

Fiberglass Reinforced Plastic (FRP) grating is a composite material that has gained immense popularity across various industries due to its exceptional durability, lightweight nature, and corrosion resistance. This innovative product combines the best attributes of fiberglass and resin, resulting in a material that is not only strong but also versatile and easy to maintain. In this article, we will delve into the characteristics, advantages, applications, and maintenance of FRP grating.

Characteristics of FRP Grating

FRP grating is primarily composed of fiberglass strands embedded in a thermosetting resin matrix. This composition grants the material its remarkable structural integrity and resistance to a variety of environmental factors. The grating is available in various forms, including molded and pultruded types, each offering unique attributes suited for specific applications. Molded grating is produced by laying fiberglass strands and resin in a mold, which is then cured to form a solid panel. Pultruded grating, on the other hand, is manufactured by pulling fiberglass strands through a resin bath and then through a heated die, resulting in a continuous, uniform product.

One of the standout features of FRP grating is its impressive load-bearing capacity. It can withstand heavy weights without deforming, making it an ideal choice for industrial applications. Additionally, FRP grating is lightweight, which simplifies installation and reduces structural support requirements, ultimately leading to cost savings.

Advantages of FRP Grating

The benefits of FRP grating are numerous. Firstly, its resistance to corrosion surpasses that of traditional materials such as steel and aluminum. This attribute is particularly advantageous in environments exposed to chemicals, saltwater, or harsh weather conditions, which can lead to rapid deterioration of conventional materials.

Secondly, FRP grating is non-conductive and non-magnetic, making it a favorable option for electrical and electronic applications. Safety is another significant advantage, as FRP grating can be produced with a slip-resistant surface, reducing the risk of accidents in workplaces.

fiberglass reinforced plastic grating

Moreover, FRP grating is easy to customize. It can be manufactured in various colors, sizes, and configurations to meet specific design requirements. This flexibility makes it suitable for a wide range of applications, from flooring in industrial plants to walkways in commercial settings.

Applications of FRP Grating

FRP grating is widely utilized in various industries, including chemical processing, wastewater treatment, oil and gas, and food processing. In the chemical industry, its corrosion resistance makes it an optimal choice for platforms, walkways, and drainage covers. In wastewater treatment facilities, FRP grating can be found in both functional and aesthetic applications, contributing to safer working environments.

In the oil and gas sector, where exposure to harsh chemicals is commonplace, FRP grating helps maintain safety standards while minimizing maintenance costs. Food processing plants also benefit from FRP grating, as it meets sanitary standards and provides a slip-resistant surface, ensuring worker safety.

Maintenance of FRP Grating

Maintenance of FRP grating is relatively straightforward. Regular cleaning with soap and water is generally sufficient to remove dirt and debris. Unlike metal grating, FRP does not require periodic painting or rust prevention treatments, making it a low-maintenance option.

In conclusion, fiberglass reinforced plastic grating represents a significant advancement in material engineering, offering a combination of strength, safety, and versatility. Its benefits have led to its widespread adoption across various industries, where it continues to play a crucial role in improving both safety and efficiency. As technology progresses, the applications and innovations surrounding FRP grating are likely to expand, further solidifying its position as a preferred material in demanding environments.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025