loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

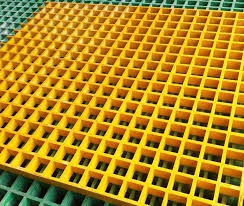

fiberglass reinforced plastic grating

The Benefits and Applications of Fiberglass Reinforced Plastic Grating

Fiberglass reinforced plastic (FRP) grating is an advanced composite material widely used in various industrial and commercial applications due to its unique properties. Combining fiberglass with a polymer resin, this grating offers significant advantages over traditional materials like steel and wood. In this article, we will explore the benefits of FRP grating, its applications, and its impact on industries.

Advantages of FRP Grating

1. Corrosion Resistance One of the most significant benefits of FRP grating is its resistance to corrosion. Unlike metal grating, which can rust when exposed to moisture and chemicals, FRP grating remains unaffected by harsh environments. This makes it an ideal choice for applications in chemical plants, wastewater treatment facilities, and marine environments where corrosive substances are prevalent.

2. Lightweight and Strong FRP grating is remarkably lightweight yet incredibly strong. This combination allows for easy installation, handling, and transport. The reduced weight translates to lower transportation costs and makes it simpler to work with on-site. Despite its lightness, FRP grating maintains high strength-to-weight ratios, enabling it to carry heavy loads without compromising its structural integrity.

3. Safety Features Safety is a critical concern in many industrial settings. FRP grating offers excellent slip resistance, reducing the risk of accidents in wet or oily environments. Additionally, it is non-conductive, making it a safe option for electrical applications and areas where electrical hazards may be present.

4. Long Lifespan The durability of FRP grating extends its lifecycle significantly. It withstands wear and tear better than wood or metal, which often require frequent replacement due to corrosion or rot. Investing in FRP grating can lead to significant cost savings over time, as maintenance and replacement expenses are minimized.

5. Customization Options FRP grating can be manufactured in various sizes, colors, and shapes to meet specific project requirements. This level of customization allows engineers and architects to incorporate FRP grating seamlessly into diverse designs and infrastructures.

fiberglass reinforced plastic grating

Common Applications

1. Industrial Flooring One of the most common uses of FRP grating is in industrial flooring systems. Its strength, corrosion resistance, and safety features make it ideal for factories, warehouses, and processing plants where heavy machinery and hazardous materials are present.

2. Walkways and Platforms FRP grating is extensively used for walkways and platforms in various settings. In the oil and gas industry, for instance, FRP grating provides safe access to drilling sites and refineries while resisting the corrosive effects of hydrocarbons.

3. Wastewater Treatment In wastewater treatment plants, FRP grating is employed for platforms, catwalks, and access covers. Its chemical resistance and ability to withstand harsh environmental conditions make it an excellent choice for this application.

4. Marine Applications The marine industry benefits greatly from FRP grating due to its ability to resist salty water and other corrosive elements found in marine environments. It is commonly used on docks, piers, and in shipbuilding.

5. Architecture and Design Beyond industrial applications, FRP grating is increasingly used in architectural designs. Its aesthetic versatility allows designers to utilize FRP in modern buildings, creating visually appealing spaces while offering functional benefits.

Conclusion

Fiberglass reinforced plastic grating represents a remarkable advancement in material science, providing a plethora of benefits that enhance safety, durability, and efficiency in various applications. As industries continue to seek cost-effective and reliable materials, FRP grating stands out as a superior alternative to traditional grating solutions. With its resistance to corrosion, lightweight nature, and customizable options, FRP grating is sure to play an increasingly prominent role in the future of construction and industrial operations. Whether used in manufacturing, marine applications, or architectural designs, the versatility and reliability of FRP grating make it an invaluable asset across multiple sectors.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025