loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

កុម្ភៈ . 19, 2025 02:27

Back to list

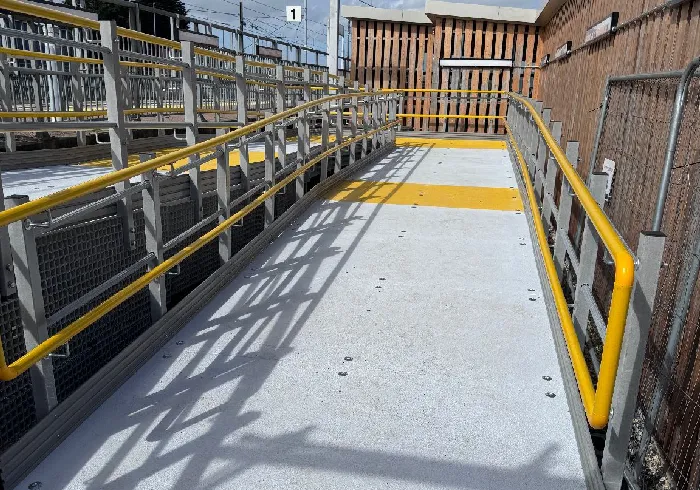

covered grating

Covered grating is a product that bridges the gap between functionality and aesthetic appeal, making it an essential component in various industrial and commercial applications. This versatile innovation is widely used in industries such as manufacturing, construction, and urban infrastructure. Understanding the unique benefits and applications of covered gratings can inform better purchasing decisions, optimizing both performance and safety.

Trustworthiness of a supplier or manufacturer plays a pivotal role in the decision-making process. When selecting covered gratings, it's prudent to consider the track record and reputation of the supplier. Companies with ISO certifications or those that provide extensive warranties and technical support are often more reliable. Testimonials from industry peers and case studies demonstrating successful applications in similar environments add layers of trust. Furthermore, a manufacturer’s commitment to innovation, as evidenced in their product lines, reflects their dedication to meeting evolving industry needs. In the context of product applications, covered gratings are employed in an array of settings. For manufacturing plants, covering trenches with these gratings prevents tools and parts from falling, reducing potential hazards. In public infrastructures like walkways and bridges, they serve as efficient drainage solutions without compromising safety. Moreover, architectural projects aiming for modern aesthetics can incorporate covered gratings that blend seamless functionality with contemporary design. Available in customizable colors and patterns, they add visual appeal to any project, merging utility with elegance. An often-overlooked benefit of covered gratings is their contribution to sound attenuation. In environments prone to high noise levels, such as power plants or heavy machinery sites, the covered top acts as a barrier, helping to dampen sound waves and creating a more pleasant auditory environment. In summary, covered gratings are an indispensable product that offers a comprehensive solution to safety, durability, and maintenance challenges. They not only meet but often exceed industry standards, ensuring that businesses are equipped with reliable flooring solutions. Investing in high-quality covered gratings translates to long-term cost savings, enhanced safety, and improved operational efficiency, thereby delivering exceptional value to any organization that prioritizes performance and safety.

Trustworthiness of a supplier or manufacturer plays a pivotal role in the decision-making process. When selecting covered gratings, it's prudent to consider the track record and reputation of the supplier. Companies with ISO certifications or those that provide extensive warranties and technical support are often more reliable. Testimonials from industry peers and case studies demonstrating successful applications in similar environments add layers of trust. Furthermore, a manufacturer’s commitment to innovation, as evidenced in their product lines, reflects their dedication to meeting evolving industry needs. In the context of product applications, covered gratings are employed in an array of settings. For manufacturing plants, covering trenches with these gratings prevents tools and parts from falling, reducing potential hazards. In public infrastructures like walkways and bridges, they serve as efficient drainage solutions without compromising safety. Moreover, architectural projects aiming for modern aesthetics can incorporate covered gratings that blend seamless functionality with contemporary design. Available in customizable colors and patterns, they add visual appeal to any project, merging utility with elegance. An often-overlooked benefit of covered gratings is their contribution to sound attenuation. In environments prone to high noise levels, such as power plants or heavy machinery sites, the covered top acts as a barrier, helping to dampen sound waves and creating a more pleasant auditory environment. In summary, covered gratings are an indispensable product that offers a comprehensive solution to safety, durability, and maintenance challenges. They not only meet but often exceed industry standards, ensuring that businesses are equipped with reliable flooring solutions. Investing in high-quality covered gratings translates to long-term cost savings, enhanced safety, and improved operational efficiency, thereby delivering exceptional value to any organization that prioritizes performance and safety.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025