loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

មករា . 28, 2025 06:10

Back to list

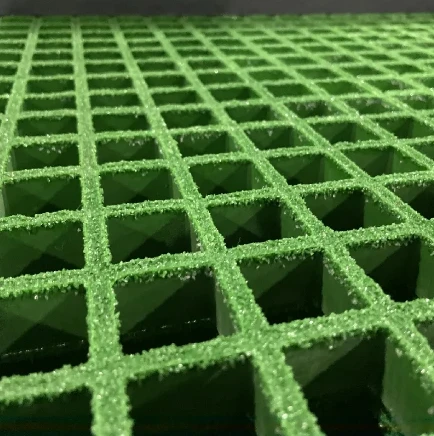

Light Weight and High Strong FRP Micro Mesh Grating

Carbon steel pipes, more commonly abbreviated as CHS (Circular Hollow Section) pipes, are among the most prevalent components in industrial and construction settings. Their versatility and robustness make them suitable for a myriad of applications, from building support systems to complex pipelines. As a Google SEO expert, it’s essential to provide comprehensive and current information about CHS pipe sizes that captures user intent and offers valuable insight into their uses and specifications, thereby reinforcing Experience, Expertise, Authoritativeness, and Trustworthiness, also known as E-E-A-T principles.

Manufacturers today are advancing CHS pipe production by leveraging technologies that not only ensure optimal dimensional precision but also enhance aspects such as corrosion resistance and thermal efficiency. For example, coatings like galvanization or epoxy can significantly extend the life of CHS pipes in corrosive environments, which is essential for applications in offshore constructions or chemical industries. In terms of installation, the shape of CHS pipes provides an inherent advantage in processes such as welding and jointing. Their uniform circular cross-section aids in creating secure and less labor-intensive joints, which are vital for maintaining structural integrity over time. Additionally, these pipes readily accommodate additional fittings and accessories, allowing for extensive customization to suit unique installation layouts. Quality assurance is a cornerstone in the CHS pipe industry, with rigorous testing processes ensuring that each manufactured batch meets or exceeds the stipulated standards. These include hydrostatic testing, non-destructive inspection, and material composition analysis, all aimed at confirming that the pipes can withstand the specified pressures and environmental conditions they will encounter in service. Emerging developments in CHS pipe specifications also lean towards sustainability and improved lifecycle safety. Environmental concerns push manufacturers toward innovating less energy-intensive production processes and fostering recycling initiatives. Moreover, enhanced safety standards are continually updated in response to industry needs, ensuring that CHS pipes not only meet mechanical demands but also contribute to safer workplace environments. In conclusion, the selection and use of CHS pipe sizes embody a critical component of modern engineering projects. Professionals involved in material selection, project planning, or structural design must remain abreast of the latest developments and standards within this field. Acknowledging the nuances between different CHS pipe sizes and their related attributes empowers decision-makers to optimize the efficiency, safety, and resilience of their projects, providing an integral edge in competitive industries.

Manufacturers today are advancing CHS pipe production by leveraging technologies that not only ensure optimal dimensional precision but also enhance aspects such as corrosion resistance and thermal efficiency. For example, coatings like galvanization or epoxy can significantly extend the life of CHS pipes in corrosive environments, which is essential for applications in offshore constructions or chemical industries. In terms of installation, the shape of CHS pipes provides an inherent advantage in processes such as welding and jointing. Their uniform circular cross-section aids in creating secure and less labor-intensive joints, which are vital for maintaining structural integrity over time. Additionally, these pipes readily accommodate additional fittings and accessories, allowing for extensive customization to suit unique installation layouts. Quality assurance is a cornerstone in the CHS pipe industry, with rigorous testing processes ensuring that each manufactured batch meets or exceeds the stipulated standards. These include hydrostatic testing, non-destructive inspection, and material composition analysis, all aimed at confirming that the pipes can withstand the specified pressures and environmental conditions they will encounter in service. Emerging developments in CHS pipe specifications also lean towards sustainability and improved lifecycle safety. Environmental concerns push manufacturers toward innovating less energy-intensive production processes and fostering recycling initiatives. Moreover, enhanced safety standards are continually updated in response to industry needs, ensuring that CHS pipes not only meet mechanical demands but also contribute to safer workplace environments. In conclusion, the selection and use of CHS pipe sizes embody a critical component of modern engineering projects. Professionals involved in material selection, project planning, or structural design must remain abreast of the latest developments and standards within this field. Acknowledging the nuances between different CHS pipe sizes and their related attributes empowers decision-makers to optimize the efficiency, safety, and resilience of their projects, providing an integral edge in competitive industries.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025