loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Understanding Various Pipe Sizes for Effective Fluid Dynamics in CHS Systems

Understanding CHS Pipe Sizes A Comprehensive Overview

When it comes to construction and engineering, the choice of piping material plays a crucial role in the success of any project. One of the widely used materials is Circular Hollow Sections (CHS), which are essential in various applications due to their strength, versatility, and ease of use. This article aims to delve into the different sizes of CHS pipes, discussing their applications, advantages, and important considerations in selection.

What are CHS Pipes?

Circular Hollow Sections are steel tubes characterized by a hollow, cylindrical shape. They are manufactured through a process of rolling or welding steel plates into a circular form. CHS pipes are categorized into various sizes based on their outer diameter (OD) and wall thickness, making them suitable for a diverse range of applications, from structural frameworks to plumbing.

Understanding CHS Pipe Sizes

CHS pipe sizes are often specified by their outer diameter and wall thickness. Commonly measured in millimeters, the sizes can range from small diameters of around 20 mm to large sizes exceeding 600 mm. Standard thicknesses typically range from 1.5 mm to 12 mm, which is crucial for determining the pipe's load-bearing capacity and resistance to environmental factors.

For example, a CHS pipe with an outer diameter of 100 mm and a wall thickness of 5 mm can be utilized for medium loads in structural applications, while a larger pipe with an outer diameter of 450 mm and a wall thickness of 10 mm may be used in heavy-duty situations, such as in the construction of bridges or tall buildings.

Applications of CHS Pipes

CHS pipes are incredibly versatile and find their place in a variety of industries. One of the most prominent applications is in the construction sector. They are commonly used as columns, beams, and frameworks that provide structural support. Their circular shape offers superior strength and stability, particularly when dealing with compression and torsional loads.

In addition to construction, CHS pipes are utilized in the automotive industry for manufacturing components that require strength and lightweight characteristics. They are also employed in the furniture industry, as they can be used to create stylish, modern designs that are both functional and durable.

chs pipe sizes

Moreover, CHS pipes are frequently used for fencing and safety barriers due to their robustness and resistance to bending. Industries such as oil and gas, infrastructure, and marine also benefit from the use of CHS pipes for pipelines and structural supports primarily due to their durability and resistance to corrosion.

Advantages of CHS Pipes

One of the main advantages of using CHS pipes is their high strength-to-weight ratio. This characteristic allows for the construction of lighter structures without sacrificing integrity. This not only reduces material costs but also simplifies transportation and installation.

Another significant benefit of CHS pipes is their aesthetic appeal. The smooth, round shape can be visually appealing in exposed architecture, offering a modern touch to various projects. Furthermore, their continuous surface allows for easy painting and coating, enhancing their corrosion resistance and longevity.

CHS pipes are also very effective in load distribution. Their circular cross-section allows for uniform distribution of stress, making them ideal for applications that involve high loads or dynamic forces.

Important Considerations in Selection

While choosing the right CHS pipe, several factors should be taken into consideration. The load requirements, environmental conditions, and specific application requirements are crucial in determining the appropriate size and thickness. Additionally, it is essential to consider the material specifications, such as the yield strength and ductility, particularly for structural applications.

Moreover, understanding the local building codes and regulations is vital to ensure compliance and safety in construction projects. The standards may dictate specific requirements for pipe sizes based on the application and intended use.

Conclusion

In summary, CHS pipes are an indispensable material in modern construction and engineering due to their size variability, strength, and versatility. Understanding the different CHS pipe sizes and their applications is essential for professionals in various industries to make informed decisions that affect both project outcomes and safety. Whether for structural support, automotive components, or aesthetic applications, CHS pipes offer a reliable solution that meets the diverse needs of today's engineering challenges.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

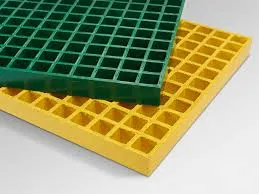

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025