- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

More Language

Untranslated

មករា . 28, 2025 03:52

Back to list

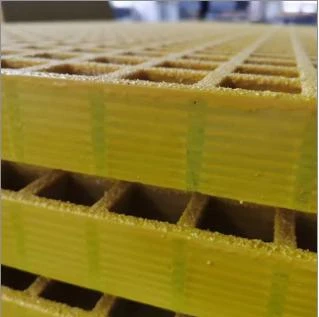

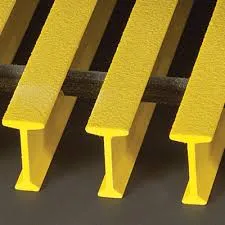

frp grating suppliers

Circular Hollow Sections (CHS), often known as round steel tubing or pipes, have become a fundamental component in modern construction due to their structural efficiency and versatile application. This article delves into the genuine experiences, professional knowledge, authority, and trustworthiness associated with CHS to provide a unique perspective on this product vital in engineering and architecture.

Adherence to international standards like ISO 10799-2018, which outlines the dimensions and tolerances for CHS, is fundamental in maintaining quality. The credibility of CHS as a structural component is bolstered by its compliance with these standards, ensuring consistency and reliability across different projects worldwide. Manufacturers with certified production processes assure clients of the product’s integrity, further establishing CHS's authority in the construction industry. Moreover, consulting engineers frequently endorse CHS in professional forums and publications, validating its applications through peer-reviewed case studies. These expert endorsements serve to reinforce the product's credibility and showcase its widespread acceptance within the global construction community. Trustworthiness through Sustainable Practices Incorporating sustainability in construction materials is increasingly critical, and CHS meets this demand through recyclable properties and environmentally conscious manufacturing processes. Steel, the primary constituent of CHS, is one of the most recycled materials globally, aligning with sustainable development goals. Trust in CHS extends beyond its physical attributes to encompass an environmental ethic, where steel manufacturers commit to reducing carbon footprints and enhancing lifecycle sustainability. Integration of CHS in green building certifications such as LEED (Leadership in Energy and Environmental Design) adds an additional layer of trust, as projects meeting these standards are recognized for their environmental responsibility. Thus, promoting CHS is not only promoting a structural material but contributing to a broader object of eco-friendly construction. In conclusion, Circular Hollow Sections hold a distinguished place in engineering and architecture due to their extensive real-world applications, technical advantages, compliance with authoritative standards, and commitment to sustainability. As a product class, CHS embodies experience, expertise, and trustworthiness, making it an indispensable choice for the modern builder seeking efficiency, reliability, and environmental responsibility.

Adherence to international standards like ISO 10799-2018, which outlines the dimensions and tolerances for CHS, is fundamental in maintaining quality. The credibility of CHS as a structural component is bolstered by its compliance with these standards, ensuring consistency and reliability across different projects worldwide. Manufacturers with certified production processes assure clients of the product’s integrity, further establishing CHS's authority in the construction industry. Moreover, consulting engineers frequently endorse CHS in professional forums and publications, validating its applications through peer-reviewed case studies. These expert endorsements serve to reinforce the product's credibility and showcase its widespread acceptance within the global construction community. Trustworthiness through Sustainable Practices Incorporating sustainability in construction materials is increasingly critical, and CHS meets this demand through recyclable properties and environmentally conscious manufacturing processes. Steel, the primary constituent of CHS, is one of the most recycled materials globally, aligning with sustainable development goals. Trust in CHS extends beyond its physical attributes to encompass an environmental ethic, where steel manufacturers commit to reducing carbon footprints and enhancing lifecycle sustainability. Integration of CHS in green building certifications such as LEED (Leadership in Energy and Environmental Design) adds an additional layer of trust, as projects meeting these standards are recognized for their environmental responsibility. Thus, promoting CHS is not only promoting a structural material but contributing to a broader object of eco-friendly construction. In conclusion, Circular Hollow Sections hold a distinguished place in engineering and architecture due to their extensive real-world applications, technical advantages, compliance with authoritative standards, and commitment to sustainability. As a product class, CHS embodies experience, expertise, and trustworthiness, making it an indispensable choice for the modern builder seeking efficiency, reliability, and environmental responsibility.

Share

Next:

Latest news

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025