loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

កុម្ភៈ . 19, 2025 04:41

Back to list

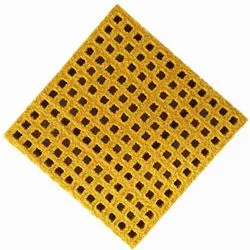

grp mini mesh grating

Fiberglass grating, specifically the 4x8 variety, has become an indispensable material across various industries, known for its unique properties and versatility. Designed to address the complications associated with traditional metal grates, this modern alternative offers a suite of benefits, making it a top choice for engineers and facility managers aiming for reliable, durable, and cost-effective solutions.

Thermal and electrical conductivity are other areas where fiberglass grating outshines traditional materials. Being non-conductive, it serves as a safer option in environments where electrical hazards are a concern. The temperature stability of fiberglass ensures that it retains integrity under high-heat conditions, unlike metal grates that may warp or melt under similar circumstances. These properties make 4x8 fiberglass grating suitable for installations in chemical plants and areas with stringent safety codes. Customization is another aspect where 4x8 fiberglass grating offers undeniable value. Its adaptability allows for a wide range of applications, customized to fit unique space requirements. Whether it’s a custom color to match corporate aesthetics or a specific configuration to fit complex architectures, fiberglass grating offers the flexibility that other materials cannot. This degree of customization does not compromise the integrity or performance of the grating. Furthermore, fiberglass grating is a sustainable option for businesses aiming to reduce their environmental footprint. Unlike metal, which requires considerable energy to mine and refine, fiberglass grating is manufactured through less energy-intensive processes. This makes it an environmentally responsible choice for companies looking to meet sustainability goals while maintaining operational efficiency. 4x8 fiberglass grating stands out as a pioneering solution for modern industrial challenges. Its remarkable attributes of durability, ease of maintenance, superior safety, and sustainability are transforming industries worldwide. By investing in this innovative material, businesses not only enhance their operational efficiency and safety but also make a positive stride towards sustainability and cost-effectiveness. Given its myriad advantages, it is clear why fiberglass grating is becoming the standard choice for contemporary industrial applications.

Thermal and electrical conductivity are other areas where fiberglass grating outshines traditional materials. Being non-conductive, it serves as a safer option in environments where electrical hazards are a concern. The temperature stability of fiberglass ensures that it retains integrity under high-heat conditions, unlike metal grates that may warp or melt under similar circumstances. These properties make 4x8 fiberglass grating suitable for installations in chemical plants and areas with stringent safety codes. Customization is another aspect where 4x8 fiberglass grating offers undeniable value. Its adaptability allows for a wide range of applications, customized to fit unique space requirements. Whether it’s a custom color to match corporate aesthetics or a specific configuration to fit complex architectures, fiberglass grating offers the flexibility that other materials cannot. This degree of customization does not compromise the integrity or performance of the grating. Furthermore, fiberglass grating is a sustainable option for businesses aiming to reduce their environmental footprint. Unlike metal, which requires considerable energy to mine and refine, fiberglass grating is manufactured through less energy-intensive processes. This makes it an environmentally responsible choice for companies looking to meet sustainability goals while maintaining operational efficiency. 4x8 fiberglass grating stands out as a pioneering solution for modern industrial challenges. Its remarkable attributes of durability, ease of maintenance, superior safety, and sustainability are transforming industries worldwide. By investing in this innovative material, businesses not only enhance their operational efficiency and safety but also make a positive stride towards sustainability and cost-effectiveness. Given its myriad advantages, it is clear why fiberglass grating is becoming the standard choice for contemporary industrial applications.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025