loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Ақп . 17, 2025 13:18

Back to list

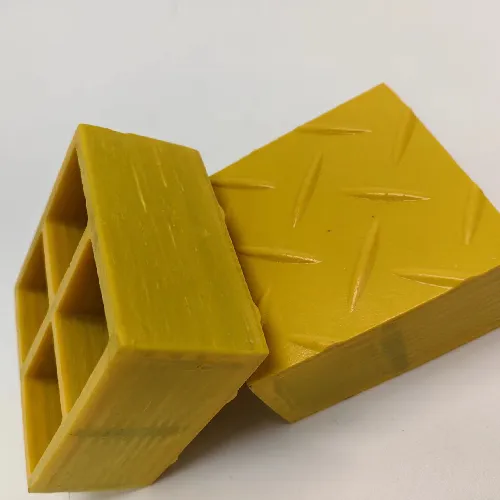

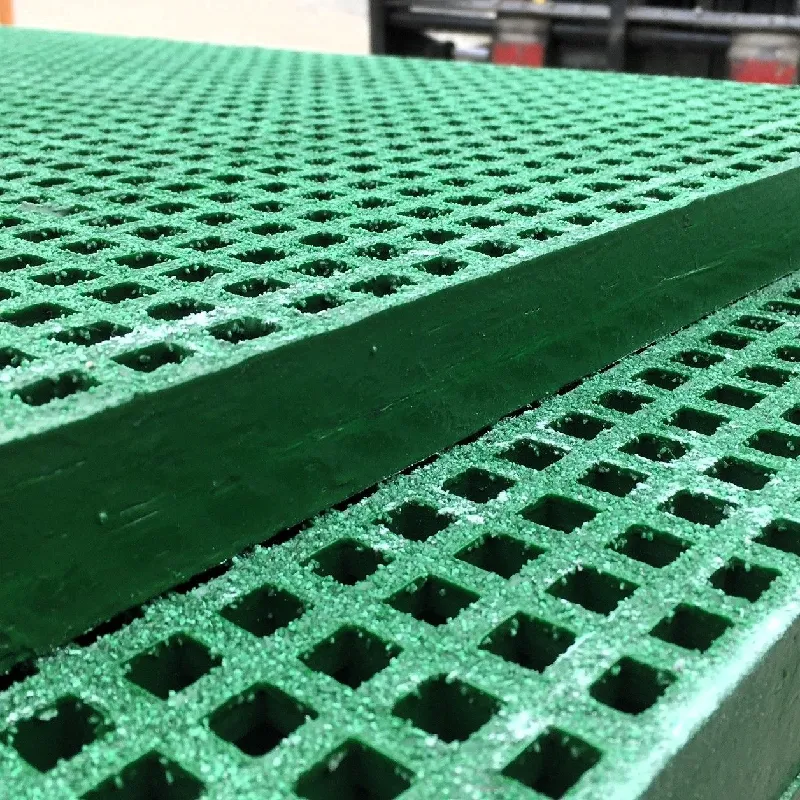

Smaller Open Mesh Area FRP Mini Mesh Grating

In the realm of construction and industrial applications, the selection of materials can significantly impact the longevity, safety, and efficiency of a project. One such material that has been gaining attention for its impressive properties is GRP (Glass Reinforced Plastic) used in grating systems. These systems have become integral in a myriad of industries due to their advanced features and benefits. This article explores the distinct advantages that GRP grating systems offer, highlighting their real-world applications, expert insights, authority in the field, and the trust they garner among industry professionals.

In real-world applications, GRP grating systems have been successfully implemented across a vast array of industries. In the marine sector, for example, they provide robust walkways and platforms that endure both saltwater corrosion and the mechanical stress from heavy foot traffic. Similarly, in the oil and gas industry, GRP gratings are preferred for offshore rigs where a combination of harsh weather conditions and corrosive environments present a formidable challenge. Feedback from experts in these fields have continuously confirmed that GRP systems outperform and outlast other materials when subjected to identical conditions. Furthermore, the environmental aspect of GRP is another reason why it is becoming the material of choice for sustainable construction. The manufacturing process of GRP has a lower carbon footprint compared to the production of traditional materials, aligning with the global push towards more environmentally friendly construction practices. As an influential player in sustainability, GRP is likely to see increased usage as industries evolve to meet new environmental regulations. The trust placed in GRP grating systems by engineers and construction professionals is a testament to their reliability and effectiveness. Thorough testing and compliance with international standards reassure stakeholders of the quality and performance of GRP products. Manufacturers of GRP grating systems often provide comprehensive warranties and extensive customer support, further enhancing their trustworthiness and credibility in the market. In conclusion, GRP grating systems stand as a superior choice for industries seeking durable, safe, and cost-effective solutions for their operations. The blend of advanced material properties, expert endorsements, established authority, and trusted performance positions GRP as a leading solution in the evolving landscape of industrial materials. For those tasked with the responsibility of choosing the right materials for their projects, GRP grating systems present an unequivocal option that promises long-term benefits and satisfaction.

In real-world applications, GRP grating systems have been successfully implemented across a vast array of industries. In the marine sector, for example, they provide robust walkways and platforms that endure both saltwater corrosion and the mechanical stress from heavy foot traffic. Similarly, in the oil and gas industry, GRP gratings are preferred for offshore rigs where a combination of harsh weather conditions and corrosive environments present a formidable challenge. Feedback from experts in these fields have continuously confirmed that GRP systems outperform and outlast other materials when subjected to identical conditions. Furthermore, the environmental aspect of GRP is another reason why it is becoming the material of choice for sustainable construction. The manufacturing process of GRP has a lower carbon footprint compared to the production of traditional materials, aligning with the global push towards more environmentally friendly construction practices. As an influential player in sustainability, GRP is likely to see increased usage as industries evolve to meet new environmental regulations. The trust placed in GRP grating systems by engineers and construction professionals is a testament to their reliability and effectiveness. Thorough testing and compliance with international standards reassure stakeholders of the quality and performance of GRP products. Manufacturers of GRP grating systems often provide comprehensive warranties and extensive customer support, further enhancing their trustworthiness and credibility in the market. In conclusion, GRP grating systems stand as a superior choice for industries seeking durable, safe, and cost-effective solutions for their operations. The blend of advanced material properties, expert endorsements, established authority, and trusted performance positions GRP as a leading solution in the evolving landscape of industrial materials. For those tasked with the responsibility of choosing the right materials for their projects, GRP grating systems present an unequivocal option that promises long-term benefits and satisfaction.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025