loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Industrial Water Treatment Solutions and Equipment for Efficient Water Management Systems

Industrial Water Treatment Equipment Essential Solutions for Sustainable Operations

In the ever-evolving landscape of industrial operations, the demand for efficient and sustainable water treatment solutions is more critical than ever. As industries strive to meet regulatory standards and minimize environmental impact, the importance of industrial water treatment equipment has surged. This article explores the various types of equipment used in industrial water treatment, their significance, and the best practices for implementing them effectively.

Understanding Industrial Water Treatment

Industrial water treatment refers to the processes and technologies employed to manage water used in various industrial activities, such as manufacturing, mining, and energy production. The primary goal is to remove contaminants and pollutants from water before it is discharged back into the environment or reused in production processes. This not only helps preserve water resources but also ensures compliance with environmental regulations.

Types of Industrial Water Treatment Equipment

1. Preliminary Treatment Systems Preliminary treatment equipment includes screens, grit chambers, and sedimentation tanks. These systems are essential for removing large particles, debris, and sediment from industrial effluents. By preventing larger contaminants from entering more complex treatment processes, preliminary systems enhance the overall efficiency and effectiveness of water treatment.

2. Filtration Systems Filtration is crucial in removing suspended solids and particulate matter from water. Various filtration methods can be utilized, including sand filters, multimedia filters, and membrane filtration systems. Each offers unique advantages, with membrane filtration, such as microfiltration, ultrafiltration, and reverse osmosis, providing high levels of purification by separating contaminants at the molecular level.

3. Chemical Treatment Equipment Chemical treatment involves adding specific chemicals to water to coagulate and flocculate suspended impurities, making them easier to remove. Equipment like chemical dosing systems and mixing tanks are vital in this phase. Other methods incorporate oxidation and disinfection techniques that utilize chlorine, ozone, or ultraviolet light to eliminate pathogens and harmful chemicals.

4. Biological Treatment Systems Biological treatment employs microorganisms to degrade organic matter in wastewater effectively. Aerobic and anaerobic treatment systems—such as activated sludge systems and bioreactors—are commonly used. These systems are environmentally friendly and can be incredibly efficient in treating organic-rich wastewater.

5. Sludge Management Equipment The process of water treatment produces sludge, which requires proper disposal or treatment. Equipment such as centrifuges, belt filter presses, and digesters are used to manage and dewater sludge effectively. This not only minimizes the volume of waste but can also convert sludge into biosolids that can be repurposed in agriculture.

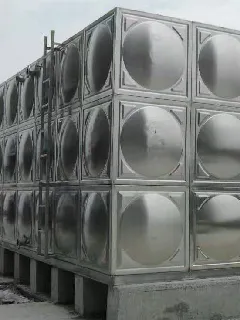

industrial water treatment equipment

The Importance of Industrial Water Treatment Equipment

Investing in appropriate water treatment equipment is crucial for industries aiming to improve sustainability and reduce operational costs. Efficient water treatment systems help ensure high-quality water for production processes, minimize water waste, and protect the environment from harmful pollutants. Additionally, facilities that implement effective water treatment methods can enhance their reputation and comply with stringent regulatory standards, thereby mitigating legal risks and avoiding potential fines.

Best Practices for Implementing Water Treatment Solutions

1. Conduct a Comprehensive Water Audit Understand the specific requirements of your industry and the types of contaminants present in your water sources. This information can guide the selection of appropriate water treatment technologies.

2. Invest in Advanced Technologies Consider utilizing state-of-the-art equipment that offers automation, monitoring, and control capabilities. Advanced technologies can improve treatment efficiency and reduce operational costs.

3. Regular Maintenance and Monitoring Implement a routine maintenance schedule for all water treatment equipment to ensure optimal performance. Continuous monitoring allows for quick identification and resolution of potential issues.

4. Employee Training Ensure that staff are adequately trained in operating and maintaining water treatment systems. Knowledgeable employees can contribute significantly to the efficiency of water treatment processes and overall safety.

5. Sustainability Initiatives Explore ways to recycle and reuse water within the facility. This can significantly reduce water demand and lower costs while supporting environmental sustainability goals.

Conclusion

Industrial water treatment equipment is indispensable for industries seeking to enhance sustainability and operational efficiency. By understanding the various types of equipment available and implementing best practices, businesses can not only comply with regulations but also contribute positively to the environment. As industries continue to innovate, the future of water treatment holds great potential for achieving sustainable industrial practices.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025