loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

1月 . 09, 2025 11:38

Back to list

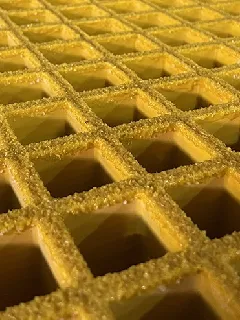

frp pultruded gratings

When thinking about industrial and commercial flooring solutions, the conversation often gravitates toward traditional materials such as steel and wood. However, the rise of pultruded FRP (Fiber Reinforced Plastic) grating is redefining expectations. With intrinsic qualities that lend themselves to high performance and durability, pultruded FRP grating is swiftly becoming the backbone of modern flooring solutions.

Safety, a paramount priority in industrial and commercial settings, is another area where FRP grating stands out. Its inherent non-slip surface texture enhances traction, thereby reducing the risk of slips and injuries. Moreover, being non-conductive, it provides an extra layer of protection against electrical hazards, which is crucial in environments with heavy electrical equipment use. Equally important is the environmental quotient of pultruded FRP grating. As industries push towards more sustainable operations, FRP grating presents an excellent eco-friendly option. Its long-lasting nature minimizes the need for frequent replacements, reducing the carbon footprint associated with manufacturing and transport. Additionally, many manufacturers are now opting for greener resin choices, further aligning the product with global sustainability goals. The trustworthiness of pultruded FRP grating stems from years of rigorous testing and real-world application. Many industry experts and engineers attest to its reliability based on exhaustive evaluations and successful deployment in critical infrastructures. This granular level of validation reinforces confidence in its performance capabilities. In summary, pultruded FRP grating transcends traditional material limitations, providing a superior alternative that addresses both current and future industrial demands. Its seamless blend of strength, safety, versatility, and sustainability rightly positions it as a material of choice for progressive firms seeking to optimize operational efficiency and safety.

Safety, a paramount priority in industrial and commercial settings, is another area where FRP grating stands out. Its inherent non-slip surface texture enhances traction, thereby reducing the risk of slips and injuries. Moreover, being non-conductive, it provides an extra layer of protection against electrical hazards, which is crucial in environments with heavy electrical equipment use. Equally important is the environmental quotient of pultruded FRP grating. As industries push towards more sustainable operations, FRP grating presents an excellent eco-friendly option. Its long-lasting nature minimizes the need for frequent replacements, reducing the carbon footprint associated with manufacturing and transport. Additionally, many manufacturers are now opting for greener resin choices, further aligning the product with global sustainability goals. The trustworthiness of pultruded FRP grating stems from years of rigorous testing and real-world application. Many industry experts and engineers attest to its reliability based on exhaustive evaluations and successful deployment in critical infrastructures. This granular level of validation reinforces confidence in its performance capabilities. In summary, pultruded FRP grating transcends traditional material limitations, providing a superior alternative that addresses both current and future industrial demands. Its seamless blend of strength, safety, versatility, and sustainability rightly positions it as a material of choice for progressive firms seeking to optimize operational efficiency and safety.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025