loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

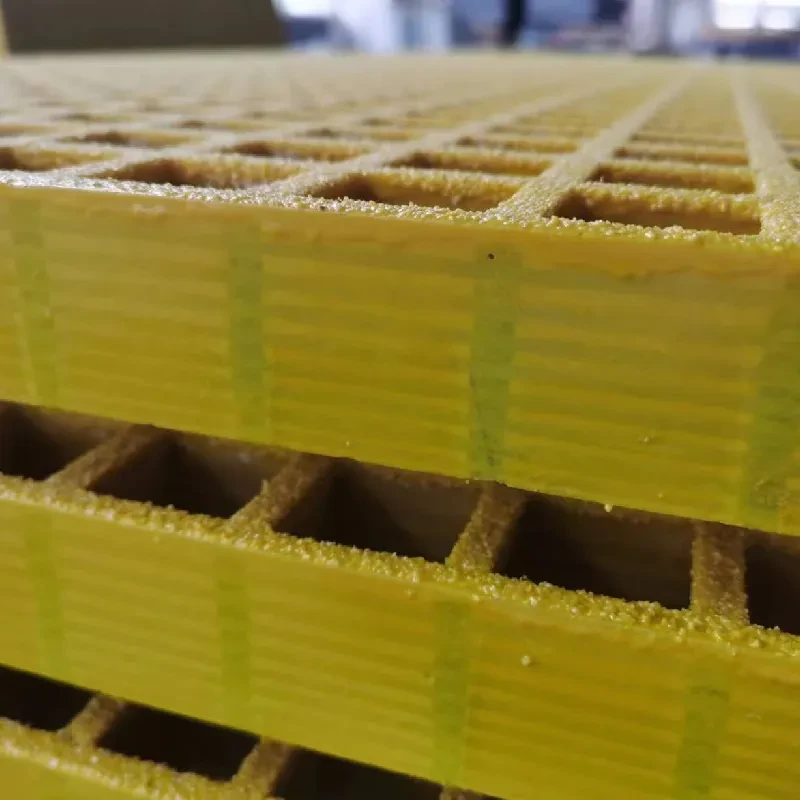

frp platform grating

Exploring FRP Platform Grating A Versatile Solution for Modern Infrastructure

In the realm of civil engineering and construction, the selection of materials plays a pivotal role in the longevity, safety, and functionality of structures. Among the innovative materials gaining attention in various applications is Fiber Reinforced Plastic (FRP) grating. This article delves into the properties, advantages, and applications of FRP platform grating, shedding light on its significance in modern infrastructure.

What is FRP Grating?

FRP grating is a type of flooring system made from a composite material of plastic reinforced with fibrous glass strands. This combination provides a high strength-to-weight ratio, making the grating both lightweight and exceptionally strong. Typically available in a range of designs, including molded and pultruded options, FRP grating is favored for its durability, low maintenance requirements, and resistance to corrosive environments.

Advantages of FRP Platform Grating

1. Corrosion Resistance One of the standout characteristics of FRP grating is its resistance to corrosion. Unlike traditional materials such as steel, which can succumb to rust in harsh environments, FRP remains unaffected by chemical exposure. This makes it an ideal choice for industries like wastewater treatment, chemical processing, and marine applications, where materials are often subject to corrosive agents.

2. Lightweight Nature The lightweight properties of FRP grating facilitate easier handling and installation. This characteristic not only reduces transportation costs but also minimizes the need for heavy lifting equipment during the construction process. As a result, projects can be completed more efficiently, saving time and labor costs.

3. Safety Features Safety is paramount in any industrial or infrastructural setting. FRP grating is equipped with anti-slip surfaces, which enhance traction even in wet or oily conditions. This feature significantly reduces the risk of slips and falls, making it a preferred choice for platforms, walkways, and staircases in various applications.

4. Low Maintenance Needs With its inherent resistance to environmental factors, FRP grating requires minimal maintenance. It does not need to be painted or treated regularly, allowing for reduced lifecycle costs and making it a budget-friendly choice for long-term projects.

frp platform grating

5. Versatility FRP grating can be tailored to fit numerous applications, from pedestrian walkways and vehicular access platforms to scaffolding and machinery platforms. Its adaptable nature allows it to be custom-fabricated to meet specific project requirements, enhancing its utility across different sectors.

Applications of FRP Platform Grating

- Industrial Environments Many industrial facilities utilize FRP grating for walkways, platforms, and staircases due to its ability to withstand heavy loads and resist corrosive substances. This is particularly valuable in chemical production plants, oil and gas processing facilities, and other heavy industries.

- Marine Applications Given its resistance to seawater, FRP grating is widely employed in marine environments. Applications include docks, piers, and boat maintenance areas, where traditional materials would deteriorate rapidly.

- Wastewater Treatment In wastewater treatment plants, the need for durable and corrosion-resistant materials is critical. FRP grating serves as an excellent choice for walkways and platforms where exposure to harsh chemicals and moisture is often unavoidable.

- Infrastructure Projects FRP grating is increasingly being integrated into public infrastructure, such as bridges and highways, owing to its durable properties and lighter weight compared to traditional materials.

Conclusion

As industries evolve and the demand for reliable, sustainable materials grows, FRP platform grating emerges as a vital solution. Its unique properties—corrosion resistance, lightweight design, safety features, low maintenance, and versatility—make it an ideal choice for a variety of applications in modern infrastructure. By embracing materials like FRP grating, industries can enhance operational efficiency while ensuring safety and sustainability, paving the way for a stronger foundation in future construction endeavors.

-

Revolutionary Modular Handrail Systems Redefine Safety StandardsNewsMay.15,2025

-

Innovative Water Treatment Technologies for Purer WaterNewsMay.15,2025

-

Innovative Square Water Tank SystemsNewsMay.15,2025

-

Innovative Galvanized Steel Water TanksNewsMay.15,2025

-

Innovative FRP Grating Products Revolutionize Industrial FlooringNewsMay.15,2025

-

Fiberglass Storage Tanks for Reliable Water SolutionsNewsMay.15,2025

-

The Benefits and Uses of Covered Grating SolutionsNewsMay.12,2025