loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

24 x 72 frp vessel

Understanding the 24% FRP Vessel A Closer Look at Its Applications and Benefits

In the realm of engineering and industrial applications, the choice of materials is crucial for the design and functionality of vessels used in various processes. Among these materials, Fiber Reinforced Plastic (FRP) has gained significant attention due to its unique properties and advantages over traditional materials. In this article, we will explore the characteristics, applications, and benefits of a 24% FRP vessel, particularly in the context of a 72-liter capacity.

What is FRP?

Fiber Reinforced Plastic (FRP) is a composite material made from a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. The combination of these materials results in a lightweight but incredibly strong structure. The percentage of fiber content plays a significant role in the overall performance of the FRP vessel. In our case, a 24% FRP vessel contains 24% fiber by weight.

Characteristics of 24% FRP Vessel

1. Strength and Durability The incorporation of 24% fibers enhances the mechanical strength of the vessel, allowing it to withstand higher pressure and resist deformation. This property is particularly beneficial in applications where the vessel is subjected to harsh conditions.

2. Corrosion Resistance One of the standout features of FRP is its resistance to corrosion. Unlike metal vessels, which can corrode over time when exposed to chemicals or moisture, a 24% FRP vessel remains unaffected by a wide range of aggressive substances. This makes it an ideal choice for chemical storage and transport.

3. Lightweight Compared to traditional materials such as steel or aluminum, FRP vessels are significantly lighter. This characteristic facilitates easier handling, transport, and installation, ultimately leading to cost savings.

4. Thermal Insulation FRP has excellent thermal insulation properties, making it suitable for applications that require temperature management. A 24% FRP vessel can maintain the temperature of its contents, reducing energy consumption in temperature-sensitive processes.

Applications of 24% FRP Vessels

The versatility of 24% FRP vessels allows their use in various industries

24 x 72 frp vessel

1. Chemical Industry Due to their superior corrosion resistance, 24% FRP vessels are widely used in the chemical industry for storing and transporting various chemicals, including acids, bases, and solvents.

2. Water Treatment In water treatment facilities, FRP vessels can be used for processes such as filtration, sedimentation, and chemical dosing. Their resistance to corrosion and ability to withstand a range of pH levels make them a preferred choice.

3. Food and Beverage Industry For the food industry, maintaining hygiene is paramount. FRP vessels can be designed to meet stringent health and safety regulations, making them suitable for storing food materials and beverages without risk of contamination.

4. Oil and Gas In the oil and gas sector, FRP vessels are used for storing and transporting various hydrocarbons. Their durability and resistance to chemical reactions make them ideal for this environment.

Advantages of Using 24% FRP Vessels

1. Cost-Effective Although the initial investment in FRP might be higher than traditional materials, the long-term savings through reduced maintenance costs and increased operational efficiency make it a cost-effective solution.

2. Environmental Impact The lightweight nature of FRP vessels results in lower transportation emissions. Additionally, their long lifespan reduces the need for replacements, leading to less waste.

3. Customizability FRP technology allows for the creation of vessels tailored to specific applications, including custom shapes, sizes, and features. This adaptability provides industries with the flexibility they need to meet their unique requirements.

Conclusion

In summary, a 24% FRP vessel with a capacity of 72 liters embodies many of the desirable traits of modern engineering materials. Its strength, durability, corrosion resistance, and lightweight nature make it an excellent choice for various industrial applications. As industries continue to seek ways to enhance efficiency and sustainability, the adoption of materials like FRP is likely to grow. Understanding the benefits and applications of such vessels will be key for engineers and decision-makers in various sectors, ensuring that they can leverage the advantages of this remarkable technology.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

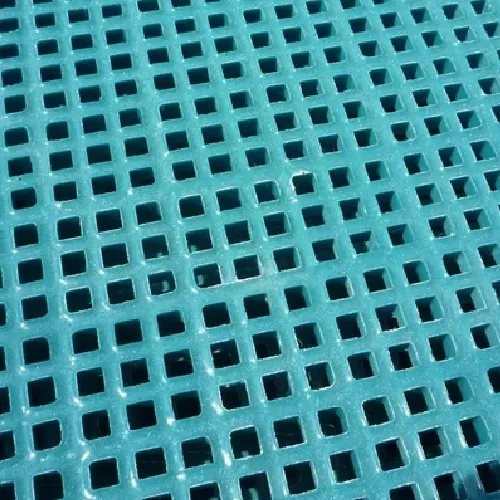

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025