loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

High-Strength GRP Platform Solutions – Easy GRP Platform Steps & FRP Platform Grating

Elevate Your Space: Why a GRP Platform Is the Ultimate Solution for Safe, Durable, and Cost-effective Access

Imagine this: a typical industrial plant, thousands of square feet covered in rusted metal walkways. Each year, corrosion eats away at supports. Slip accidents rise. OSHA violations pile up. Productivity drops as maintenance costs soar.

Sound familiar? You’re not alone. According to a 2023 OSHA report, over 16% of all industrial accidents are directly linked to poor platform safety and corrosion. Companies lose millions in repairs and downtime. Staff hesitate to use old, unsafe walkways—a liability no modern site can afford.

But there’s a game-changing alternative sweeping through industries—introducing the GRP platform. Get ready to transform your facility’s safety, efficiency, and value—fast, and with style.

(grp platform)

What Is a GRP Platform? Breaking Down the Technical Advantages

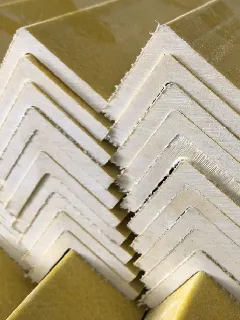

First things first: “GRP” stands for Glass Reinforced Plastic, sometimes known as FRP (Fiber Reinforced Polymer). A GRP platform is a modular structure built using high-strength composite panels, typically utilizing FRP platform grating. So, what makes this material so different?

- Corrosion resistance: GRP doesn’t rust, doesn’t rot—ideal for demanding outdoor or industrial environments.

- Lightweight strength: 30% lighter than steel, it supports heavy loads (up to 5,000 lbs/sq ft in some specs).

- Electrical insulation: GRP is non-conductive, reducing the risk of electrical hazards.

- Anti-slip safety: Aggressive grit surfaces minimize slips—even when wet or greasy.

- Low maintenance: No repainting, no constant checks, no lost weekends on upkeep.

- Fast installation: Pre-fabricated GRP platform steps snap together, keeping downtime to a minimum.

Here’s a quick look at how GRP platform grating outperforms traditional materials:

| Feature | Steel | Concrete | GRP/FRP |

|---|---|---|---|

| Weight | Heavy | Very Heavy | Lightweight |

| Corrosion | High | Medium | Zero |

| Maintenance | Frequent | Patch/Repair | Minimal |

| Anti-Slip | Low | Low | High |

| Fire Resistance | Variable | Good | Very Good |

Want technical specs? Here’s a common GRP platform grating configuration:

| Spec | Typical Value |

|---|---|

| Panel Thickness | 1" (25mm) |

| Open Area | 68% |

| Load Capability | >500 lbs/sqft |

| Fire Rating | ASTM E84 Class 1 |

| Surface Finish | Anti-slip Grit (Silica) |

How Does a GRP Platform Manufacturer Stack Up?

Your choice of supplier can make or break your project. Reliable, experienced GRP platform manufacturers deliver:

- Consistent product quality. No warping, no sub-standard resins.

- Full load test certificates and safety ratings—no uncertainties.

- Precision-cut fittings for exact project requirements.

- Clear, helpful customer support from quote to install.

- Short lead times—avoid project delays and cost overruns.

But not all are created equal. Some import cheap resin. Others cut corners on fiber glass content. Here’s what to ask when comparing manufacturers:

- Do you supply ASTM/ISO test data on all FRP platform grating?

- Are your platforms manufactured in ISO-certified facilities?

- What’s your average lead time per order?

- Can you provide references and case studies?

- Is installation support provided?

Choose a manufacturer who stands by their product. It pays off in long-term reliability, safety, and ROI.

From Blueprint to Installation: The GRP Platform Steps to a Custom Solution

Every site is different. So, you need a modular system that adapts to your layout—fast. Here’s how leading suppliers streamline the grp platform

steps for you:

- Consultation: Tell us your site challenges, dimensions, and regulatory needs.

- Site Survey: (Optional) A team visits your facility for measurements and hazard analysis.

- AutoCAD Design: Receive detailed drawings and 3D renders ensuring exact fit.

- Fabrication: All GRP/FRP platform grating and supports are precision-cut and prefabricated.

- Fast Delivery: All pieces labeled and packaged for rapid on-site assembly.

- Hassle-Free Install: Assembly is intuitive. Step-by-step guides reduce installation time by up to 60%.

- Ongoing Support: Questions? Warranty issues? Your partner supports you long-term.

Customization makes every dollar count. Your platform fits your process—no compromise, no wasted materials.

Real-World GRP Platform Application Cases

Wondering if a GRP platform fits your sector? Just look at these use cases:

- Oil & Gas: Offshore platforms switch to FRP grating for saltwater resistance.

- Water Treatment Plants: Improve walkway safety; no more rust near chlorine tanks.

- Manufacturing: Overhead walkways and maintenance areas built in a weekend—no facility shutdowns needed.

- Food & Beverage: Hygienic, easy-to-clean platforms under wet process zones.

- Power Plants: GRP platform steps insulate from live equipment—safety first.

- Transport Hubs: Lightweight solutions over fragile floors and mezzanines.

In every case? Downtime plummets. Accidents drop. Teams feel safer and move faster. Companies see a 25–40% reduction in platform maintenance costs within a year, based on 2022 industry surveys.

Are You Ready to Upgrade with a GRP Platform?

Still debating? Think about what a modern GRP platform could do for you: fewer injuries, lower long-term costs, happier teams, and a professional facility that welcomes audits—not fearing them.

Don’t let outdated walkways or corroded stairs slow you down. It’s time to raise the bar for safety and success. With our world-class GRP/FRP solutions, you get proven performance, expert support, and lasting value.

Ready for a quote? Or want free technical advice on the best GRP platform steps for your project?

Contact BluePeak Composites—America’s leading manufacturer of high-spec GRP and FRP platform grating. We’re here to design custom solutions, provide full documentation, and deliver support nationwide.

Don’t wait—click below for your free site assessment and discover why smart teams trust BluePeak for their GRP platform needs!

Frequently Asked Questions: GRP Platforms & Related Solutions

Q1. What is a GRP platform and where can it be used?

A GRP platform uses Glass Reinforced Plastic grating for safe walkways, stairs, and access areas. It’s used across oil & gas, chemical, water treatment, manufacturing, and more—anywhere strength, safety, and corrosion resistance matter.

Q2. What are the main GRP platform steps from design to installation?

The typical GRP platform steps include site assessment, blueprint design, prefabrication, packaging, and rapid assembly—usually with full installation support from the manufacturer.

Q3. How does GRP/FRP platform grating compare to metal or concrete?

GRP/FRP platform grating is lighter, stronger (by weight), non-conductive, won’t corrode, and has higher anti-slip performance. It also reduces maintenance costs and project downtime versus metal or concrete.

Q4. Is GRP platform grating suitable for outdoor environments?

Absolutely. GRP platform grating resists rain, salt, UV, and extreme temperatures, making it ideal for outdoor and marine applications with no risk of rust.

Q5. Can I customize the size and configuration of my GRP platform?

Yes, top suppliers let you specify width, length, load rating, surface finish, stair angles, colors, and unique layouts. You get a perfectly tailored GRP platform every time.

Q6. How long does a GRP platform last?

Industry studies show GRP platforms regularly last 25+ years in harsh industrial conditions, outlasting steel or concrete alternatives with minimal maintenance.

Q7. What certifications should I look for in GRP or FRP platform grating?

Ensure your GRP/FRP platform grating is ASTM/ISO certified, carries a fire resistance rating (like ASTM E84 Class 1), and is delivered with full manufacturer warranties for peace of mind.

(grp platform)

FAQS on grp platform

Q: What is a GRP platform?

A: A GRP platform is a structure made from Glass Reinforced Plastic, known for its strength and corrosion resistance. It is commonly used in industrial applications. These platforms are lightweight, durable, and easy to maintain.Q: What are the main steps to install a GRP platform?

A: The main steps include measuring the installation area, assembling the GRP panels, and securely anchoring the platform. Safety checks and final adjustments complete the process. Professional installation ensures optimal performance.Q: How does GRP platform grating differ from traditional metal grating?

A: GRP platform grating is lighter and more corrosion-resistant compared to traditional metal grating. It is non-conductive and requires minimal maintenance. This makes it suitable for harsh environments.Q: What are the advantages of using GRP platform steps?

A: GRP platform steps provide slip resistance, chemical resistance, and long service life. They are easy to install and require less maintenance than metal or wood. These steps are ideal for wet and hazardous environments.Q: Where are GRP platforms most commonly used?

A: GRP platforms are widely used in water treatment plants, chemical factories, and offshore installations. Their durability and safety features make them suitable for industrial settings. They are also popular in public infrastructure.-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025