loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Feb . 03, 2025 02:45

Back to list

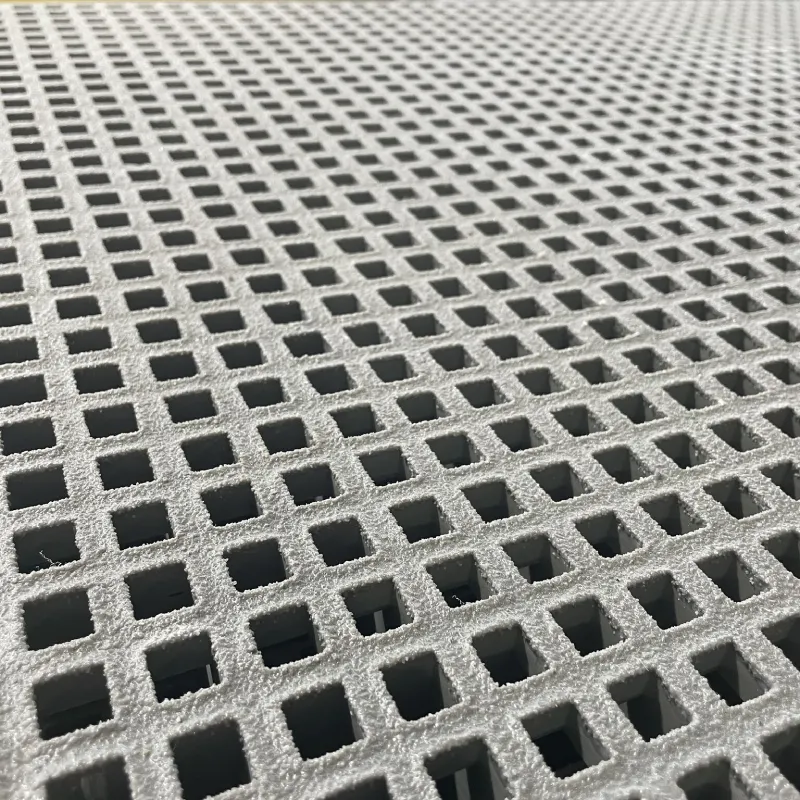

frp micro mesh grating

Fiber Reinforced Plastic (FRP) gratings have become an essential component in a variety of industries due to their robustness, corrosion resistance, and ease of installation. Their versatility makes them suitable for applications ranging from walkways in chemical plants to pedestrian bridges. Exploring the nuances of FRP grating installation not only ensures optimal performance but also enhances durability and safety.

The actual installation of FRP grating involves several critical steps. Accurate measurement and cutting of gratings to fit the designated areas without comprising their structural integrity is fundamental. Use specialized tools designed for FRP materials to avoid cracking or fracturing the gratings. Employing the correct type of fasteners is also essential, ensuring they are corrosion-resistant and suitable for the support structure material. During installation, ensure the gratings are properly aligned and securely fastened. This requires checking that the support framework is level and sturdy. Anchoring the gratings with the appropriate hardware not only stabilizes them but also prevents any unwanted movement or vibrations, which could compromise safety. Attention to detail during this phase is paramount, as improper installation can lead to accidents or the need for costly repairs. Post-installation, thorough inspection and testing should be conducted to confirm that the gratings are stable and meet all safety and performance specifications. It is advisable to perform load testing under supervised conditions to verify that the gratings can withstand the intended operational stresses. Regular maintenance checks should be scheduled to ensure that the gratings remain free of debris and potential damage points. Furthermore, training personnel on the correct usage and maintenance of the installed FRP gratings contributes to the longevity of the installation. Workers should be informed of relevant safety protocols and be equipped to identify any signs of distress in the gratings that could signal the need for immediate attention. Ultimately, successful FRP grating installation is a strategic blend of meticulous planning, expert execution, and ongoing maintenance. By focusing on these aspects, industries can significantly benefit from the economic and operational advantages offered by these advanced composite materials. Employing best practices in installation underlines not only expertise and authority within the field but also cultivates trust and reliance among stakeholders, establishing a benchmark for quality and safety that resonates throughout the industry.

The actual installation of FRP grating involves several critical steps. Accurate measurement and cutting of gratings to fit the designated areas without comprising their structural integrity is fundamental. Use specialized tools designed for FRP materials to avoid cracking or fracturing the gratings. Employing the correct type of fasteners is also essential, ensuring they are corrosion-resistant and suitable for the support structure material. During installation, ensure the gratings are properly aligned and securely fastened. This requires checking that the support framework is level and sturdy. Anchoring the gratings with the appropriate hardware not only stabilizes them but also prevents any unwanted movement or vibrations, which could compromise safety. Attention to detail during this phase is paramount, as improper installation can lead to accidents or the need for costly repairs. Post-installation, thorough inspection and testing should be conducted to confirm that the gratings are stable and meet all safety and performance specifications. It is advisable to perform load testing under supervised conditions to verify that the gratings can withstand the intended operational stresses. Regular maintenance checks should be scheduled to ensure that the gratings remain free of debris and potential damage points. Furthermore, training personnel on the correct usage and maintenance of the installed FRP gratings contributes to the longevity of the installation. Workers should be informed of relevant safety protocols and be equipped to identify any signs of distress in the gratings that could signal the need for immediate attention. Ultimately, successful FRP grating installation is a strategic blend of meticulous planning, expert execution, and ongoing maintenance. By focusing on these aspects, industries can significantly benefit from the economic and operational advantages offered by these advanced composite materials. Employing best practices in installation underlines not only expertise and authority within the field but also cultivates trust and reliance among stakeholders, establishing a benchmark for quality and safety that resonates throughout the industry.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025