loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp bars in concrete

The Role of FRP Bars in Concrete Structures

Fiber-Reinforced Polymer (FRP) bars have emerged as a revolutionary material in the construction industry, particularly for reinforcing concrete structures. Traditional steel reinforcement is susceptible to corrosion, which can compromise the integrity and longevity of buildings and infrastructure. In contrast, FRP bars offer unique advantages that address these concerns, making them a favorable choice for various applications.

What are FRP Bars?

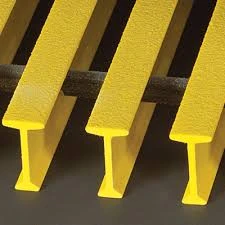

FRP bars consist of a composite material made from a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. The combination of high tensile strength provided by the fibers and the lightweight nature of polymers results in a material that significantly improves the performance of concrete structures. FRP bars can be manufactured in various shapes and sizes, tailored to specific engineering requirements.

Advantages of FRP Bars

1. Corrosion Resistance One of the most significant benefits of FRP bars is their resistance to corrosion. Unlike steel, which can rust when exposed to moisture and corrosive chemicals, FRP bars maintain their structural integrity over time, even in harsh environments such as coastal areas or industrial settings.

2. Lightweight FRP bars are considerably lighter than traditional steel reinforcement, making them easier to handle and transport. This reduces labor costs and simplifies installation, especially in locations where heavy lifting equipment may not be feasible.

3. High Strength-to-Weight Ratio Despite their light weight, FRP bars have a high tensile strength. This property allows for reduced cross-sectional areas of reinforcement, facilitating designs that save on material costs while maintaining structural performance.

4. Non-Magnetic and Non-Conductive FRP bars do not conduct electricity or interfere with magnetic fields, making them ideal for applications in sensitive electronic facilities or areas needing non-magnetic properties, such as MRI rooms.

5. Durability The inherent durability of FRP bars translates to longer service life for concrete structures, reducing the need for repairs and maintenance. This longevity translates into economic benefits over the life cycle of the structure.

frp bars in concrete

Applications of FRP Bars

FRP bars can be utilized in various concrete applications, including

- Bridge Construction Due to their corrosion resistance, FRP bars are increasingly being used in bridge construction, particularly in environments prone to de-icing salts and other corrosive elements.

- Water Retaining Structures Structures like water tanks and reservoirs benefit from the non-corrosive properties of FRP, ensuring that the structural integrity is maintained over time.

- Industrial Flooring In industrial settings where chemicals are present, FRP-reinforced concrete floors help avoid the degradation typically associated with steel reinforcement.

- Seismic Resistance In earthquake-prone areas, utilizing FRP bars can enhance the ductility and energy dissipation characteristics of concrete structures, promoting better performance during seismic events.

Challenges and Considerations

Despite the many advantages, the use of FRP bars also comes with challenges. Their higher initial cost compared to steel can deter some projects, although life cycle cost analysis often favors FRP in the long run. Additionally, designers must be familiar with the different mechanical properties of FRP, as their behavior under load can differ significantly from that of steel.

Conclusion

FRP bars represent a significant advancement in concrete reinforcement technology. Their unique properties provide solutions to some of the critical challenges faced in construction, particularly concerning durability and maintenance costs. As the demand for sustainable and long-lasting infrastructure continues to grow, the adoption of FRP bars is likely to increase, offering benefits that align with modern engineering practices and environmental considerations. By understanding and embracing these innovative materials, engineers and architects can create structures that are not only robust and reliable but also economically viable over their entire lifespan.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025