loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

feb . 10, 2025 12:18

Back to list

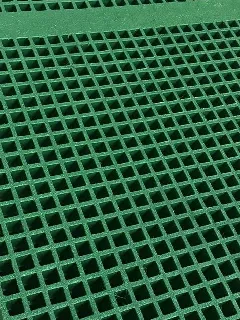

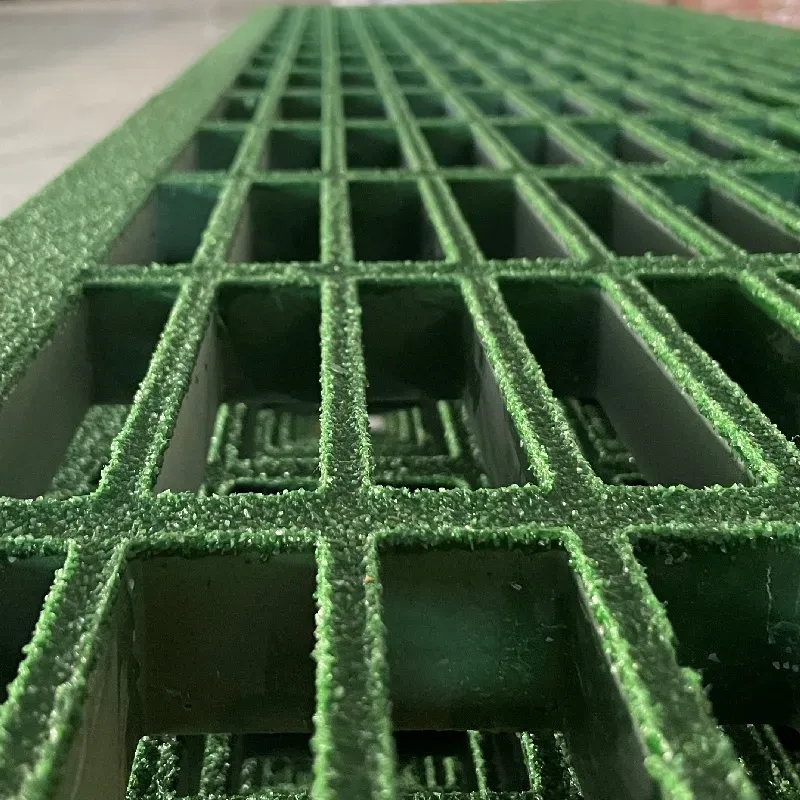

Anti- Corrosion Cost Effective FRP Pultrusion Grating

FRP pultruded gratings have emerged as a game-changer in industries that require durable, efficient, and maintenance-free solutions. Constructed using a combination of glass or carbon fibers and a polymer resin, these gratings provide unparalleled benefits due to their unique manufacturing process known as pultrusion. This innovative approach makes them ideal for a variety of industrial applications.

These gratings also play a crucial role in environmental sustainability. The manufacturing process of FRP materials typically results in lower emissions and requires less energy compared to the production of steel or aluminum components. Additionally, the longevity and durability of FRP gratings mean fewer resources are consumed over time, further solidifying their status as an eco-friendly choice for conscientious industries. Trustworthiness in the context of FRP pultruded gratings stems from rigorous testing and compliance with international safety and durability standards. Many manufacturers subject their products to extensive tests under various conditions to ensure they meet or exceed industry benchmarks. This dedication to quality assurance means that operators can have confidence in the long-term performance of their grating systems. Finally, real-world experiences from industries that have adopted FRP pultruded gratings demonstrate their value proposition. Case studies often reveal substantially reduced maintenance costs and operational downtime, adding to their allure as a preferred solution. Companies report a safer working environment, increased efficiency, and improved operational efficacy, backed by a robust after-sale support from reputable manufacturers. In conclusion, FRP pultruded gratings epitomize modern engineering ingenuity with their combination of strength, durability, safety, customization potential, and sustainability. For industries seeking to enhance their operational infrastructure while ensuring economical viability, integrating FRP pultruded gratings can provide a dynamic, trustworthy solution equipped to meet the challenges of today and the future.

These gratings also play a crucial role in environmental sustainability. The manufacturing process of FRP materials typically results in lower emissions and requires less energy compared to the production of steel or aluminum components. Additionally, the longevity and durability of FRP gratings mean fewer resources are consumed over time, further solidifying their status as an eco-friendly choice for conscientious industries. Trustworthiness in the context of FRP pultruded gratings stems from rigorous testing and compliance with international safety and durability standards. Many manufacturers subject their products to extensive tests under various conditions to ensure they meet or exceed industry benchmarks. This dedication to quality assurance means that operators can have confidence in the long-term performance of their grating systems. Finally, real-world experiences from industries that have adopted FRP pultruded gratings demonstrate their value proposition. Case studies often reveal substantially reduced maintenance costs and operational downtime, adding to their allure as a preferred solution. Companies report a safer working environment, increased efficiency, and improved operational efficacy, backed by a robust after-sale support from reputable manufacturers. In conclusion, FRP pultruded gratings epitomize modern engineering ingenuity with their combination of strength, durability, safety, customization potential, and sustainability. For industries seeking to enhance their operational infrastructure while ensuring economical viability, integrating FRP pultruded gratings can provide a dynamic, trustworthy solution equipped to meet the challenges of today and the future.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025