loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovations in Fiber-Reinforced Plastic Tanks and Vessels for Industrial Applications

Fiber Reinforced Plastic Tanks and Vessels A Modern Solution for Industrial Needs

In today's rapidly evolving industrial landscape, the demand for materials that are durable, lightweight, and resistant to corrosion and chemicals has never been greater. One such innovative solution that has gained prominence in various sectors is Fiber Reinforced Plastic (FRP). FRP tanks and vessels are revolutionizing how industries handle storage and transportation of various liquids and gases, offering numerous advantages over traditional materials like metal and concrete.

Understanding Fiber Reinforced Plastic

Fiber Reinforced Plastic, often called fiberglass, is a composite material made by combining a polymer matrix with fibrous reinforcements. These reinforcements are usually glass fibers, although other types, such as carbon or aramid fibers, can also be used depending on specific performance requirements. The incorporation of these fibers significantly enhances the mechanical properties of the plastic, providing strength, rigidity, and resilience.

Advantages of FRP Tanks and Vessels

1. Corrosion Resistance One of the primary reasons industries are opting for FRP tanks and vessels is their excellent resistance to corrosion. Unlike metal tanks, which can rust or corrode when exposed to harsh chemicals, FRP materials can withstand aggressive environments, making them ideal for the chemical, petrochemical, and wastewater treatment industries.

2. Lightweight and High Strength FRP is significantly lighter than traditional materials like steel and concrete, which reduces transportation costs and simplifies installation. Despite their lightweight nature, FRP tanks offer high structural integrity and load-bearing capacity, ensuring safety and longevity.

3. Customizability The versatility of FRP materials allows for the easy customization of tank shapes, sizes, and designs. This adaptability means that FRP tanks can be tailored to meet specific industrial requirements or spatial constraints, enhancing their utility for a diverse range of applications.

fibre reinforced plastic tanks and vessels

4. Low Maintenance Costs Due to their resistance to corrosion and chemical damage, FRP tanks often require less maintenance compared to their metal counterparts. This lower upkeep not only saves time and labor costs but also extends the lifespan of the tank or vessel.

5. Thermal Insulation FRP materials are excellent insulators, which can be beneficial for industries that require temperature control for stored materials. This property reduces energy costs and helps maintain the integrity of the contents stored within the tanks.

Applications of FRP Tanks and Vessels

The applications of FRP tanks and vessels are vast and diverse. In the chemical industry, they are commonly used for storing acids, alkalis, and other corrosive fluids. In the oil and gas sector, FRP vessels provide a lightweight solution for offshore operations where weight constraints are critical. Additionally, water treatment facilities benefit from FRP's resistance to chemical exposure when storing and processing water.

FRP tanks are also increasingly popular in agricultural applications, where they are used for storing fertilizers and pesticides, as well as in food processing, where hygiene and safety are paramount.

Conclusion

In summary, Fiber Reinforced Plastic tanks and vessels represent a significant advancement in material technology, offering a multitude of benefits over traditional options. Their corrosion resistance, lightweight nature, and customizability make them a preferred choice for various industries facing the challenges of modern storage and transport requirements. As industries continue to evolve and demand more efficient and durable solutions, FRP technology is poised to play a crucial role in shaping the future of industrial equipment and infrastructure. Whether in chemical processing, oil production, or agriculture, FRP tanks and vessels are set to become a staple in the quest for efficient and reliable storage solutions.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

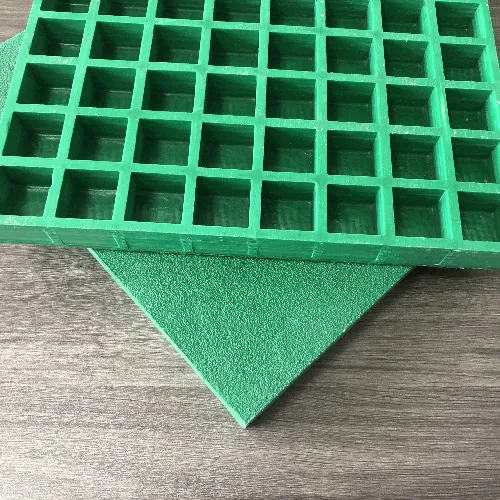

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025