loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

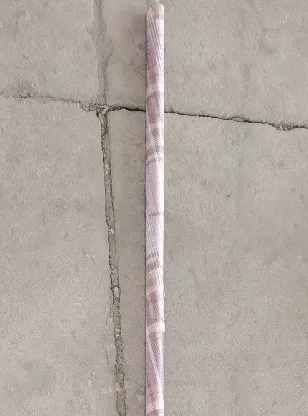

Anti- Corrosion Cost Effective FRP Pultrusion Grating

Pultruded FRP grating, often lauded for its superior strength-to-weight ratio and corrosion resistance, has emerged as a formidable solution across various industries. As a seasoned professional with extensive hands-on experience in integrating advanced materials, I’ve witnessed firsthand the transformative impact of pultruded FRP grating in demanding environments. This innovative product, fabricated through a meticulous process of pultrusion that aligns continuous strands of fiberglass with thermosetting resins, offers unparalleled durability. Unlike metallic alternatives, FRP grating is not only resistant to rust and chemical attacks but also significantly lighter, facilitating ease of installation without compromising structural integrity.

Industries from petrochemical to wastewater treatment have adopted pultruded FRP grating for its exceptional qualities. In offshore platforms, where harsh sea conditions often degrade traditional materials, FRP grating has proven to extend operational longevity. This adaptability stems from its non-conductive nature, which eliminates electrical hazards, making it an ideal choice for specific applications such as electrical substations and transformer rooms. The formulation of this grating can be specifically tailored, combining resin systems to withstand UV exposure and high temperatures, thus showcasing its versatile applicability.

From a professional standpoint, experience has shown that maintenance costs associated with FRP grating are remarkably low. This cost-effectiveness becomes evident when factoring in its long lifespan and minimal need for repairs or replacements. In contrast to metal grating, which requires periodic maintenance to combat corrosion, FRP’s inherent resistance to environmental factors presents a significant advantage. This not only reduces downtime but also lowers overall lifecycle costs, enhancing productivity in operational settings.

The credibility of pultruded FRP grating is backed by authoritative industry standards and extensive certification processes. Recognized by quality assurance organizations, these gratings comply with stringent safety and load-bearing criteria. Manufacturers have invested heavily in research and development to refine the pultrusion process, ensuring optimal performance and adherence to global standards. This underscores the trust placed by engineers and project managers worldwide in pultruded FRP solutions.

Expertise in the field of FRP technology reveals a continuous evolution of applications, driven by innovation and the demand for sustainable building materials. The eco-friendly nature of pultruded FRP grating, characterized by its reduced environmental footprint during production and long service life, aligns with contemporary green building initiatives. This commitment to sustainability is mirrored in the product’s recyclability, further cementing its position as the material of choice for forward-thinking architects and engineers.

In conclusion, pultruded FRP grating stands out not merely as a replacement for traditional materials but as a superior option that redefines expectations for safety, durability, and environmental responsibility. Its adoption is not just a testament to its technical attributes but also to the growing recognition of its unmatched benefits across multiple sectors. As industries continue to seek reliable, long-term solutions, the role of pultruded FRP grating is poised for significant expansion.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025