loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Jan . 09, 2025 12:07

Back to list

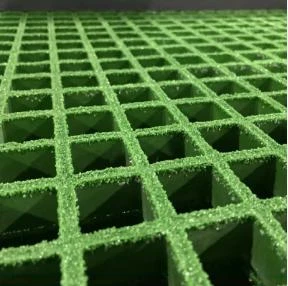

frp micro mesh grating

Fiber Reinforced Polymer (FRP) micro mesh grating has rapidly emerged as a vital material in a variety of industries due to its superior properties and versatile applications. This high-strength, lightweight alternative to traditional materials is increasingly embraced due to its combination of durability, corrosion resistance, and low maintenance requirements.

Customization of FRP micro mesh grating is another notable advantage. Manufacturers can produce grating in various sizes, colors, and thicknesses to suit specific project needs. This flexibility in design means that the grating can be tailored to fit unique applications, whether it’s a custom walkway, trench cover, or decking system. Moreover, FRP micro mesh grating supports environmental sustainability. The production process is less energy-intensive compared to metal products, and the material is fully recyclable. This aspect is particularly appealing to companies prioritizing eco-friendly practices and reducing their carbon footprint. End-users consistently report positive experiences with FRP micro mesh grating, stating that its combination of robustness and versatility outperforms traditional materials. Users in the marine industry, for example, highlight its resistance to saltwater corrosion, which extends the lifespan of marine equipment and structures. Similarly, those in the food processing industry appreciate the material's easy-to-clean surface, which complies with stringent hygiene standards. In conclusion, FRP micro mesh grating represents a forward-thinking solution in material choice that aligns with modern priorities safety, efficiency, and sustainability. As industries continue to evolve and seek materials that meet rigorous demands, the adoption of FRP micro mesh grating is poised to gain momentum. Its unparalleled benefits affirm its position as a reliable, long-term choice for challenging environments. Whether enhancing workplace safety, reducing maintenance costs, or achieving sustainability goals, FRP micro mesh grating offers a multidimensional approach that stands out as a superior alternative in today's market.

Customization of FRP micro mesh grating is another notable advantage. Manufacturers can produce grating in various sizes, colors, and thicknesses to suit specific project needs. This flexibility in design means that the grating can be tailored to fit unique applications, whether it’s a custom walkway, trench cover, or decking system. Moreover, FRP micro mesh grating supports environmental sustainability. The production process is less energy-intensive compared to metal products, and the material is fully recyclable. This aspect is particularly appealing to companies prioritizing eco-friendly practices and reducing their carbon footprint. End-users consistently report positive experiences with FRP micro mesh grating, stating that its combination of robustness and versatility outperforms traditional materials. Users in the marine industry, for example, highlight its resistance to saltwater corrosion, which extends the lifespan of marine equipment and structures. Similarly, those in the food processing industry appreciate the material's easy-to-clean surface, which complies with stringent hygiene standards. In conclusion, FRP micro mesh grating represents a forward-thinking solution in material choice that aligns with modern priorities safety, efficiency, and sustainability. As industries continue to evolve and seek materials that meet rigorous demands, the adoption of FRP micro mesh grating is poised to gain momentum. Its unparalleled benefits affirm its position as a reliable, long-term choice for challenging environments. Whether enhancing workplace safety, reducing maintenance costs, or achieving sustainability goals, FRP micro mesh grating offers a multidimensional approach that stands out as a superior alternative in today's market.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025