loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

GRP Grating Standards and Specifications for Industrial Applications and Installation Guidelines

Understanding GRP Grating Specifications

GRP (Glass Reinforced Plastic) grating is a popular choice in various industrial and commercial applications due to its unique properties and benefits. This article aims to elucidate the specifications of GRP grating, highlighting its advantages, types, applications, and considerations in selection.

What is GRP Grating?

GRP grating is a composite material made from fiberglass and plastic resin. It is commonly used as a structural component in platforms, walkways, and other applications where strength and anti-corrosive properties are essential. The manufacturing process involves layering fiberglass with a resin matrix, resulting in a lightweight yet robust product that outperforms traditional materials like steel and wood.

Key Specifications

1. Load Capacity One of the critical specifications of GRP grating is its load capacity, which is expressible in terms of load class. Typically categorized by the British Standard (BS) load classifications, GRP grating can support various loads depending on its thickness, mesh size, and resin type. It's essential to refer to load tables provided by manufacturers to ensure the selected grating meets the required specifications.

2. Panel Size GRP grating panels come in distinct dimensions, often in standard sizes such as 1m x 4m or 1m x 2m. Custom sizing is available, allowing for flexibility in design and installation. The panel thickness can vary, commonly found in 25mm, 38mm, or 50mm options, with thicker panels generally offering higher load capacities.

3. Corrosion Resistance One of the standout features of GRP is its resistance to corrosion. GRP grating is typically formulated to withstand harsh environments, making it ideal for chemical plants, wastewater treatment facilities, and coastal applications. The resin types—orthophthalic and isophthalic polyester, or vinyl ester—affect the degree of corrosion resistance; specific resins are designed for extreme conditions.

4. Slip Resistance Safety is paramount in environments where GRP grating is used. Many manufacturers include slip-resistant surfaces in their specifications, often created through a grit finish or a molded pattern. The specific slip resistance may vary, with coefficients of friction provided to help assess suitability for wet or oily environments.

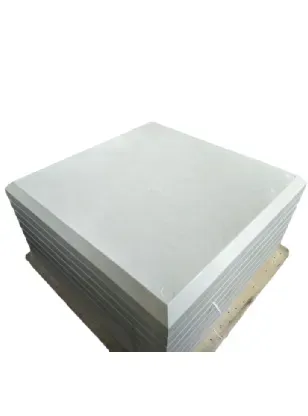

grp grating specification

5. Weight Compared to metal gratings, GRP grating is significantly lighter, often weighing only a fraction of the equivalent steel grating. This lower weight not only eases handling and installation but also reduces the load on supporting structures.

Applications

The versatility of GRP grating has led to its widespread use across various sectors. Common applications include

- Industrial Flooring GRP grating is extensively used in refineries, manufacturing plants, and warehouses where spills or chemical exposure may occur. - Walkways and Platforms With high slip resistance and corrosion resistance, GRP is an excellent choice for external walkways, utility platforms, and access points in marine environments. - Drainage Covers Recognizing its durability and drainage efficiency, GRP grating is often used in drainage systems to allow water to pass while providing solid support. - Electrical Applications GRP grating is non-conductive, making it suitable for electrical applications where safety is a concern.

Selecting the Right GRP Grating

When selecting GRP grating, several considerations should be kept in mind

- Environment Analyze the environmental conditions the grating will be subjected to and choose the resin type accordingly. - Load Requirements Ensure that the load capacities are suited to the specific application, taking into account all potential loads. - Installation and Maintenance Consider the ease of installation and the required maintenance. GRP grating is generally easy to install and requires minimal maintenance compared to traditional materials.

Conclusion

In conclusion, understanding GRP grating specifications is crucial for making informed decisions in industrial and commercial applications. Its lightweight nature, corrosion resistance, and high load-bearing capacity make it an exceptional choice for a variety of applications. By considering the essential specifications and individual project requirements, users can harness the benefits of GRP grating, ensuring safety, efficiency, and longevity in their constructions.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025