loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

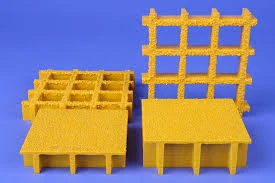

frp profiles

Understanding FRP Profiles A Comprehensive Overview

Fiber Reinforced Plastics (FRP) have become increasingly popular in various industries due to their unique properties and benefits. These materials are composed of a plastic matrix reinforced by fibers, which can be made from materials such as glass, carbon, or aramid. The combination of these materials results in profiles that offer significant advantages in terms of strength, weight, corrosion resistance, and versatility. In this article, we will explore the various aspects of FRP profiles, including their composition, benefits, applications, and future potential.

Composition of FRP Profiles

The primary components of FRP profiles are the resin and the reinforcing fibers. The resin, usually a thermosetting polymer such as epoxy, polyester, or vinyl ester, serves as the matrix that binds the fibers together. The reinforcing fibers can vary in type and orientation, influencing the overall mechanical properties of the final product. For instance, glass fibers are known for their excellent tensile strength and chemical resistance, while carbon fibers provide superior stiffness and lightweight characteristics.

The manufacturing process of FRP profiles can vary, including techniques such as pultrusion, filament winding, and resin transfer molding (RTM). Each method offers distinct advantages and is chosen based on the desired profile characteristics and application requirements.

Benefits of Using FRP Profiles

FRP profiles offer numerous benefits that set them apart from traditional materials like steel and aluminum. One of the primary advantages is their high strength-to-weight ratio. FRP profiles can be designed to be lightweight yet extremely strong, making them ideal for applications where minimizing weight is crucial, such as in aerospace and automotive industries.

Additionally, FRP materials exhibit excellent corrosion resistance. Unlike metals, FRP does not rust or corrode when exposed to harsh environmental conditions. This characteristic makes FRP profiles particularly suitable for use in industries such as marine, chemical processing, and infrastructure, where exposure to moisture and chemicals is prevalent.

frp profiles

Moreover, FRP profiles provide design flexibility. They can be molded into complex shapes and tailored to meet specific performance requirements, allowing for innovative designs that would be challenging with conventional materials. This versatility extends to color and finish options as well, enhancing aesthetic possibilities.

Applications of FRP Profiles

The applications of FRP profiles are vast and varied. In the construction industry, FRP is used for reinforcing beams, columns, and other structural components, contributing to lighter and more durable buildings. In aerospace, FRP profiles are utilized in aircraft skins and components, where weight reduction is crucial for fuel efficiency.

In the automotive sector, FRP is increasingly used for body panels, providing lightweight solutions that help improve fuel economy and reduce carbon emissions. Furthermore, in the marine industry, FRP profiles are employed in boat hulls, decks, and other components, capitalizing on their outstanding resistance to water and chemicals.

Future Potential of FRP Profiles

As the demand for sustainable materials continues to grow, FRP profiles are likely to play an increasingly important role. Innovations in recycling methods and the development of bio-based resins can further enhance the environmental profile of FRP materials. Additionally, advancements in manufacturing processes are expected to improve efficiency and reduce costs, making FRP an even more attractive option for a wide range of applications.

In conclusion, FRP profiles are a remarkable advancement in material science, offering numerous advantages over traditional materials. Their unique properties, coupled with a diverse range of applications, position them as essential components in modern engineering. As industries continue to explore innovative uses for FRP, the future looks bright for this versatile material, promising both functional excellence and environmental sustainability.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025