Explore comprehensive insights on micro mesh grating, FRP grating suppliers, and high-performance FRP grating solutions — covering manufacturing processes, technical parameters, application cases, and authoritative recommendations.

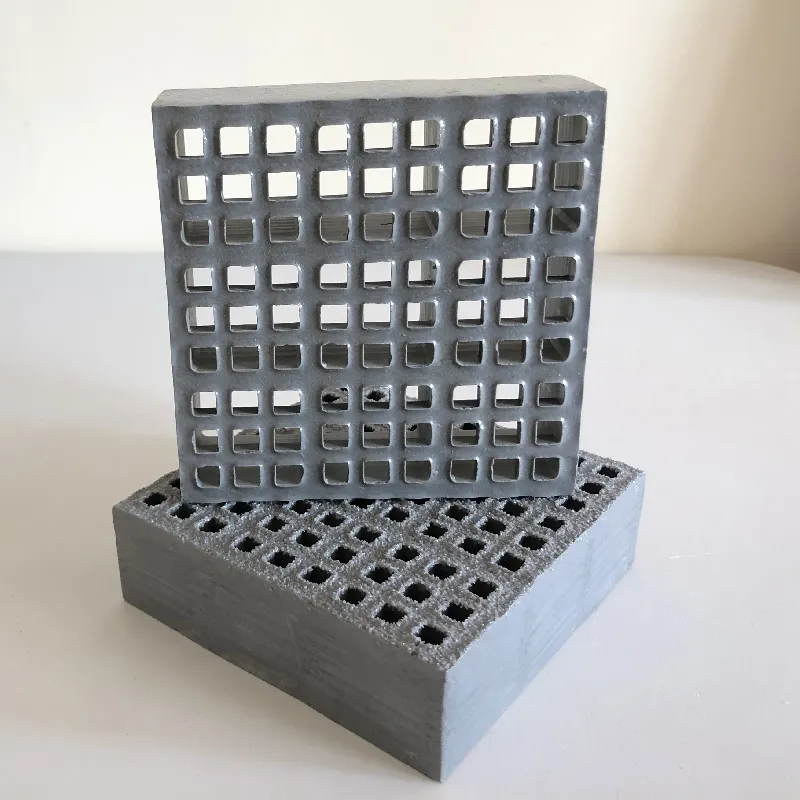

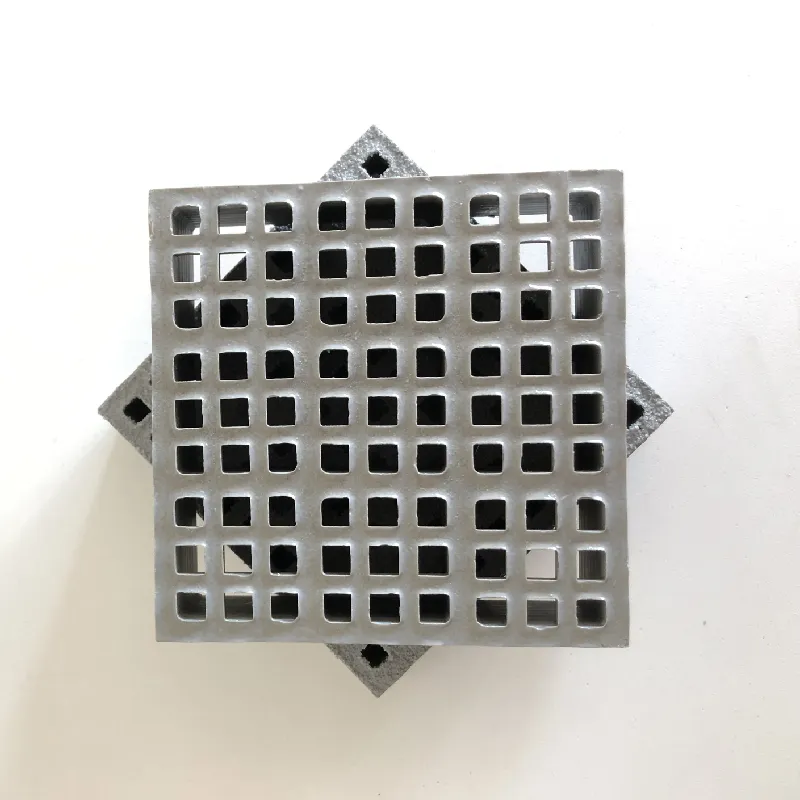

Figure 1: Micro Mesh Grating application in water treatment system

1. Industry Trends: Micro Mesh Grating & FRP Grating Innovation

In the global industrial flooring and structural support sector, micro mesh grating is rapidly gaining market share due to its outstanding corrosion resistance, high strength-to-weight ratio, and durability. According to a 2023 MarketsandMarkets report, the global fiberglass reinforced plastic (FRP grating) market is projected to reach USD 564 million by 2028, with a CAGR of 5.1%. The growing focus on lightweight, maintenance-free, and chemical-resistant solutions is driving demand for finely processed mesh grating – especially in petrochemical, metallurgy, water treatment, and food processing industries.

Not all grating is created equal. Compared to standard FRP grating, micro mesh grating offers enhanced slip resistance, finer aperture for safety, and improved anti-corrosive performance, which are crucial for high-duty operational environments and OSHA compliance.

2. Product Overview: Light Weight and High Strong FRP Micro Mesh Grating

Product Name: Light Weight and High Strong FRP Micro Mesh Grating

Product URL: https://www.zjcomposites.com/light-weight-and-high-strong-frp-micro-mesh-grating.html

Product URL: https://www.zjcomposites.com/light-weight-and-high-strong-frp-micro-mesh-grating.html

Figure 2: FRP Micro Mesh Grating for industrial walkways and anti-slip platforms

3. Manufacturing Process: Visual Flow of Micro Mesh Grating Production

Simplified FRP Micro Mesh Grating Manufacturing Flow

Resin Selection (ISO/Vinyl Ester)

→

Glass Fiber Reinforcement

→

Mixing & Molding (CNC Molded Grid)

→

Curing (High-Temp, ISO 9001-2015)

→

Demolding & Trimming

→

Quality Inspection (ANSI/ISO)

→

Cutting/Customization

→

Packing & Shipment

* Each key node (resin selection, fiber orientation, curing) is monitored for mechanical consistency and ISO/ANSI compliance.

* Watch full process video: FRP Grating Manufacturing Process Demo

* Watch full process video: FRP Grating Manufacturing Process Demo

Key Manufacturing Points Explained:

- Material: Utilizes high-grade isophthalic/vinyl ester resins for chemical resistance, and high-density E-glass fibers for tensile strength.

- Process: Precision CNC-molded casting ensures mesh uniformity, smooth edges, and consistent tolerances (±0.5mm grid accuracy).

- Standards: Fully conforms to ISO 9001:2015, ANSI/ACMA C20-14, and relevant ASTM load/deflection tests.

- Inspection: Each batch undergoes mechanical, chemical resistance, and visual QA/QC – supported by third-party test reports.

- Service Life: Proven field data indicates a typical service life of 20+ years under moderate corrosion conditions (Research Reference).

Figure 3: Automated production lines from leading frp grating suppliers

4. Technical Parameters: Micro Mesh Grating & FRP Grating Data Comparison

| Specification | Micro Mesh Grating | Standard FRP Grating | Steel Grating |

|---|---|---|---|

| Open Area (%) | 42% | 68% | 68% |

| Mesh Size (mm) | 12.7 x 12.7 | 38 x 38 | 30 x 100 |

| Panel Thickness (mm) | 25 / 30 / 38 | 25 / 38 / 50 | 25 / 30 / 38 |

| Tensile Strength (MPa) | ≥120 | ≥85 | ≥250 |

| Weight (kg/m²) | 5.2 – 9.4 | 7.8 – 13.4 | 30 – 42 |

| Slip Resistance (ASTM D2047) | ≥0.72 | ≥0.68 | 0.30–0.55 |

| Fire Resistance | UL 94 V-0 / ASTM E84 Class I | ASTM E84 Class II | Non-rated |

| Corrosion Resistance | Excellent (ISO 2812:2017) | Good | Poor |

| Maintenance | Low (5-year interval) | Medium (annual) | High (quarterly) |

Figure 4: Tensile strength and weight comparison of micro mesh grating vs. alternatives

Figure 5: Industry application share of micro mesh grating (global, 2023, %)

Figure 6: Projected service lifespan by grating type (years)

5. Supplier Insight: Comparing Leading FRP Grating Suppliers

| Supplier | Core Product | Certifications | Global Projects | Customization Support |

|---|---|---|---|---|

| ZJComposites (Recommended) | Micro Mesh Grating, Heavy Duty FRP | ISO 9001, ASTM, ANSI C20-14 | PetroChina, BASF, Govt. WWTP | Yes — Full OEM, rapid prototyping |

| Fiberglass Grating Company USA | FRP Grating Panels | ISO 9001, CE, ANSI | Shell, Louisiana Refinery | Partial (standard sizes) |

| MEISER (EU) | Steel/FRP Gratings | EN ISO 14122, ISO 9001 | Siemens, Degussa | Minimal |

| Webforge (Asia/Australia) | Metal, FRP Grating | ISO, AS, ANSI | Melbourne Water | Yes (with MOQ) |

Why Choose Leading FRP Grating Suppliers? — Top-tier manufacturers deliver traceable quality, testing transparency, full certification, and end-to-end design consultation, which is vital for complex or regulated installation environments.

6. Customization & Engineering: Tailored Solutions for Demanding Applications

- Panel Size Flexibility: Customized to fit trench covers, walkways, raised flooring, pump platforms, and complex layouts, up to 3660×1220mm format.

- Resin & Additives: Choice of Isophthalic (for general industry), Vinyl Ester (aggressive chemicals), or Phenolic (fire-critical) bases, with full pigment/color match.

- Surface Texture: Optional multi-layer anti-slip grit or smooth finish.

- UV & Fire Retardant: Integrated according to ASTM E84, UL 94 or special project needs.

- Precision Cutting & CNC Drilling: Ensures exact edge fit and tolerance for modular integration.

- Turnkey Engineering: Includes design validation, load simulation (FEA), installation drawings, on-site support.

Case Example: Customized 30mm thick micro mesh FRP grating with R13 grit, fully compliant to ISO 14122 and EN safety standards, delivered for an EU wastewater plant in Q4 2023.

7. Application & Case Studies: Micro Mesh Grating in Real-World Use

- Petrochemical: Installed as non-sparking, anti-slip walkways at Sinopec pipeline facilities — zero corrosion-related downtime over 4 years of deployment.

- Municipal Water Treatment: Used in inflow screens and walkways at Shanghai WWTP — minimized replacement cycles and enhanced safety.

- Food Processing: “Clean-grid” micro mesh grating installed at EU seafood plants for hygienic, non-porous flooring, meeting FDA 21 CFR 177.2420 sanitize standards.

- Metallurgy: Supporting acid tank platforms at Baosteel, providing >15 years maintenance-free lifespan.

- Marine & Offshore: Platform covers for new North Sea rigs, designed for salt-fog ISO 9227 tolerance and minimum 18-year service life.

Client Feedback:

“Switched to ZJ composite micro mesh grating for pump station walkways — we saw a 70% reduction in slip incidents and no visible corrosion after 3 winters. The support for custom shapes and ISO documentation was excellent.”— Engineering Project Manager, Eastern Europe Water Utility

8. Delivery, Warranty & Service Commitments

- Standard Lead Time: 7–15 days for standard panel orders; custom size or resins: 2–4 weeks ex-works.

- Warranty: Up to 15 years against manufacturing defects; 5-year anti-corrosion guarantee (terms apply).

- Quality Assurance: Each consignment supplied with full materials traceability, third-party test certificates, EN/ISO compliance forms.

- After-Sales Support: 24/7 online technical advice, on-site guidance available by appointment.

- Sample Service: Free micro mesh grating samples (standard dimensions) by express courier for industrial clients.

9. FAQ: Expert Answers on Micro Mesh Grating, FRP Grades, Standards & Installation

Q1: What is the core material of micro mesh grating?

The core is E-glass fiber reinforced with isophthalic or vinyl ester thermosetting resin. This combination provides superior strength and chemical resistance compared to polyester variants.

Q2: How does micro mesh grating differ from traditional FRP grating?

Micro mesh grating features a finer mesh (typically 12.7x12.7mm), reducing slip and improving load distribution, while standard FRP grating has larger apertures (up to 38x38mm).

Q3: What are the primary international standards relevant to FRP grating?

Main standards include ISO 9001:2015 (quality), ANSI/ACMA C20-14 (structural loading), ASTM E84 (fire), and FDA 21 CFR for food hygienic contact where required.

Q4: What fire and corrosion resistance can be achieved?

Fire retardant grade achieves ASTM E84 Class I. Corrosion resistance is validated to ISO 2812:2017 (accelerated chemical ageing).

Q5: What is the typical lifespan and maintenance schedule?

Average service life is 20–25 years in moderate corrosion; cleaning every 1–2 years and visual inspection is sufficient.

Q6: How is installation performed?

Panels are cut to size with diamond-tipped saws; fastened using FRP- or stainless-steel clips in compliance with ISO 14122-2 safety standards.

Q7: What is the maximum load capacity for micro mesh grating panels?

Load capacity varies with thickness and span; for 38mm thick panel at 600mm span, point load exceeds 4800N (Tested: ANSI C20-14).

10. References & Further Reading

- MarketsandMarkets: Global FRP Grating Market Growth

- ResearchGate: Durability of FRP Composite Gratings

- Eng-Tips Forum: FRP Grating Application Discussions

- CompositesWorld: Design Guide for FRP Grating

- ASTM: FRP Product Standards Overview

Industry references: Forums, journal studies & standards quoted are available online. For the latest FRP grating advisories, see

CompositesWorld

and

Eng-Tips Engineering Forums.