loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

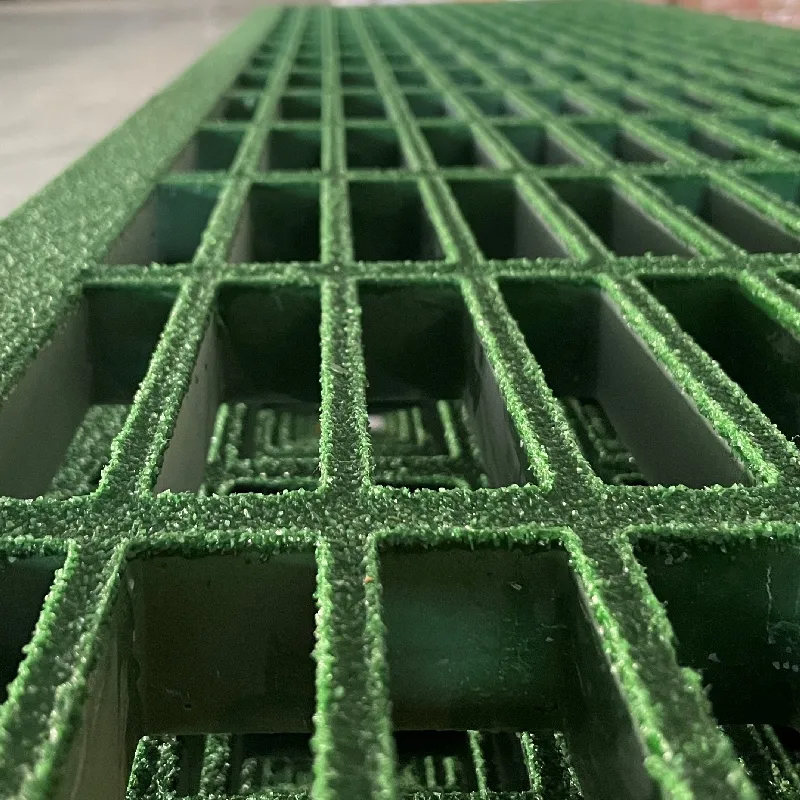

Innovative Technologies in Molded Fiberglass Reinforced Plastics for Enhanced Applications

The Advantages and Applications of Molded FRP (Fiber Reinforced Polymer)

Molded Fiber Reinforced Polymer (FRP) has become a pivotal material in various industries due to its outstanding mechanical properties and versatility. This composite material combines a polymer matrix—typically a thermoset resin like epoxy or polyester—with reinforcing fibers, usually glass, carbon, or aramid. The result is a lightweight yet incredibly strong material that can outperform traditional materials like steel and aluminum in many applications.

Properties of Molded FRP

One of the most notable characteristics of molded FRP is its high strength-to-weight ratio. This means that structures made from FRP can be much lighter than their metal counterparts while retaining or exceeding strength and durability. Additionally, molded FRP exhibits excellent corrosion resistance, making it suitable for environments that would typically cause metal corrosion, such as marine settings or chemical processing plants. The non-conductive nature of molded FRP is another asset, as it minimizes electrical hazards, making it a favorable choice for electrical applications.

Another significant advantage of molded FRP is versatility in design. The material can be molded into complex shapes and custom forms, offering design flexibility that is often difficult to achieve with metals. This flexibility enables the creation of tailored products that meet specific design requirements in industries like automotive, aerospace, and construction.

Applications of Molded FRP

Given its advantageous properties, molded FRP is utilized in a wide range of applications. In the construction industry, it is frequently used for structural components, such as beams, columns, and reinforcements. The fire resistance of specific FRP materials also makes them suitable for applications in buildings, particularly where safety standards require enhanced fire performance.

molded frp

The transportation sector has increasingly adopted molded FRP for use in vehicle manufacturing. For example, the automotive industry utilizes molded FRP in producing lighter vehicle bodies, which contributes to better fuel efficiency and reduced emissions. Meanwhile, the aerospace sector benefits from the lightweight and strong characteristics of FRP, using it in aircraft components to enhance performance without adding excessive weight.

Another rapidly growing application area is wind energy. Molded FRP is used to manufacture wind turbine blades, which demand a combination of strength, lightweight, and aerodynamic properties. The innovation in FRP technology allows for the production of longer blades, significantly improving the energy capture and efficiency of wind turbines.

Future Trends in Molded FRP

As industries continue to seek materials that offer sustainability and efficiency, the future of molded FRP looks promising. Innovations in eco-friendly resin systems and the use of recycled fibers are driving the development of more sustainable FRP products. Research into biocomposites—where natural fibers are blended with polymer matrices—demonstrates great potential, especially in reducing the environmental impact of composite production.

In addition, advancements in manufacturing techniques, such as automated fiber placement and 3D printing, are enhancing the precision and efficiency of FRP production. These innovations are expected to lower costs and promote wider adoption across various sectors, further establishing molded FRP as a fundamental material in modern engineering.

Conclusion

Molded FRP represents a significant advancement in material science, offering unparalleled strength, versatility, and durability. As industries demand more efficient and lightweight solutions, the applications of molded FRP will continue to expand. With ongoing research and development leading to more sustainable practices and innovative manufacturing techniques, molded FRP is likely to play a crucial role in the evolution of materials used across various sectors. It will shape the future of engineering, significantly contributing to innovations that demand efficiency, performance, and environmental responsibility.

-

The Benefits and Uses of Covered Grating SolutionsNewsMay.12,2025

-

SMC Panel Tanks: The Best Choice for Modern Water StorageNewsMay.12,2025

-

Sectional Water Tanks for Every NeedNewsMay.12,2025

-

FRP Profiles: A Strong Solution for Modern ApplicationsNewsMay.12,2025

-

FRP Pressure Tanks and VesselsNewsMay.12,2025

-

All You Need to Know About FRP Grating SolutionsNewsMay.12,2025

-

Why FRP Grating Panels are the Best Choice for Your Industrial NeedsNewsMay.09,2025