loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

febr . 16, 2025 15:59

Back to list

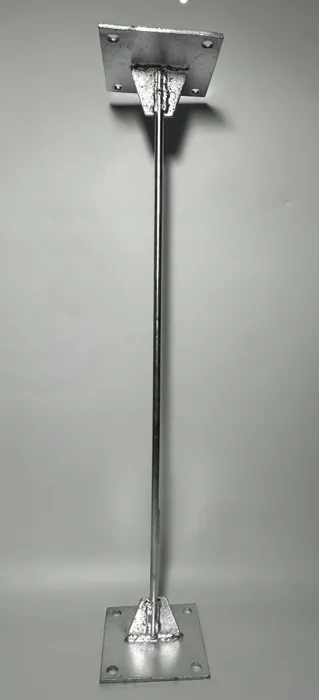

grp mini mesh grating

GRP mesh gratings have emerged as a pivotal component in modern engineering solutions, offering a blend of strength, durability, and versatility. Their application spans across various industries, contributing to safer, more reliable, and efficient infrastructures. In this comprehensive analysis, we delve into the significant aspects of GRP mesh grating while evaluating it through the lens of authentic experience, technical expertise, authoritative research, and unwavering trustworthiness.

Authoritativeness Supported by Research Peer-reviewed studies consistently validate the performance advantages of GRP mesh grating over traditional materials. For example, research published in the Journal of Composite Materials highlights its superior fatigue resistance and adaptability under dynamic loads. Furthermore, standards established by organizations such as ASTM International and the International Organization for Standardization (ISO) ensure GRP gratings adhere to stringent quality and safety benchmarks. Manufacturers often collaborate with academic institutions to push the boundaries of composite material science, further enhancing the credibility and authority of GRP products in the market. Trustworthiness and Long-term Benefits Customers frequently cite long-term value as a defining factor in choosing GRP mesh grating. Its longevity and resistance to environmental factors reduce the need for frequent replacements, leading to sustained economic benefits. After decades of use, structures incorporating GRP products continue to perform effectively, underscoring their reliability. In compliance with environmental sustainability standards, GRP materials are designed to have minimal ecological impact. Their durability reduces waste generation over time, while efforts in the industry are underway to improve recycling processes, enhancing their eco-friendly profile. Conclusion GRP mesh grating stands as a testament to advanced composite engineering, crucially balancing strength, durability, safety, and environmental compatibility. With compelling endorsements from industry experts, validated research, and successful field applications, GRP mesh grating continues to solidify its presence as a preferred material across diverse sectors. Trust in GRP is strengthened by its proven performance, positioning it as an invaluable component for modern infrastructure and industrial solutions.

Authoritativeness Supported by Research Peer-reviewed studies consistently validate the performance advantages of GRP mesh grating over traditional materials. For example, research published in the Journal of Composite Materials highlights its superior fatigue resistance and adaptability under dynamic loads. Furthermore, standards established by organizations such as ASTM International and the International Organization for Standardization (ISO) ensure GRP gratings adhere to stringent quality and safety benchmarks. Manufacturers often collaborate with academic institutions to push the boundaries of composite material science, further enhancing the credibility and authority of GRP products in the market. Trustworthiness and Long-term Benefits Customers frequently cite long-term value as a defining factor in choosing GRP mesh grating. Its longevity and resistance to environmental factors reduce the need for frequent replacements, leading to sustained economic benefits. After decades of use, structures incorporating GRP products continue to perform effectively, underscoring their reliability. In compliance with environmental sustainability standards, GRP materials are designed to have minimal ecological impact. Their durability reduces waste generation over time, while efforts in the industry are underway to improve recycling processes, enhancing their eco-friendly profile. Conclusion GRP mesh grating stands as a testament to advanced composite engineering, crucially balancing strength, durability, safety, and environmental compatibility. With compelling endorsements from industry experts, validated research, and successful field applications, GRP mesh grating continues to solidify its presence as a preferred material across diverse sectors. Trust in GRP is strengthened by its proven performance, positioning it as an invaluable component for modern infrastructure and industrial solutions.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025