loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

steel chs sizes

Understanding Steel Channel Sizes A Comprehensive Guide

Steel channels, often referred to as C-channels due to their C-shaped cross-section, are among the most versatile structural steel products. They are extensively used in construction and manufacturing processes, owing to their strength, durability, and adaptability. Understanding the various sizes of steel channels is essential for engineers, architects, and contractors to ensure that they select the right materials for their projects.

Overview of Steel Channel Sizes

Steel channels come in a range of sizes and thicknesses, designed to meet different load-bearing requirements and construction specifications. The sizing typically follows standardized dimensions, which facilitates easier design and integration into building plans. The American Society for Testing and Materials (ASTM) provides standardized sizes, categorized by their depth, width, and weight per unit length.

A steel channel's designation usually begins with C, followed by a set of numbers that denote its dimensions. For instance, a channel labeled as C6x5x1/2 indicates that it has a depth of 6 inches, a flange width of 5 inches, and a thickness of ½ inch.

Key Factors in Choosing the Right Size

1. Load Capacity When selecting a steel channel, the load it needs to support is paramount. The channel's depth, flange width, and thickness directly influence its load-bearing capabilities. A deeper and wider channel can typically carry more weight.

2. Span Length In construction, the span length refers to the distance between supports. The appropriate channel size must be chosen based on how far it needs to span without additional support.

3. Material Strength Different grades of steel possess varying strengths. Common grades include ASTM A36, A572, and A992, each with unique properties that affect performance. The choice of material plays a crucial role in determining the required size of the channel.

steel chs sizes

4. Environmental Factors The environment where the channel will be used—whether it is exposed to corrosive elements, temperature fluctuations, or heavy moisture—can dictate the need for specific size and finishing treatments, like galvanization, to enhance durability.

5. Building Codes Compliance with local building codes and regulations is essential when selecting steel channels. Different regions may have specific requirements regarding size, thickness, and material specifications that must be adhered to.

Common Sizes of Steel Channels

Standard steel channels range from small sizes such as C3x5.7 (3 inches deep, 5.7 pounds per foot) to larger dimensions like C12x20 (12 inches deep, 20 pounds per foot). The most common sizes utilized in construction tend to fall within the following ranges

- Small Channels C3 to C6, commonly used in lightweight applications such as framing and supports for smaller structures. - Medium Channels C7 to C12, frequently employed in floor systems, beams, and larger supports. - Large Channels C14 and above, typically used in heavy-duty constructions like bridge frameworks, industrial buildings, and structural support in large commercial structures.

Fabrication and Customization

While standard sizes and shapes are widely available, many projects require custom channel sizes. Manufacturers can fabricate channels to specific lengths and dimensions based on project needs, which can improve the efficiency of construction and reduce waste.

Conclusion

Selecting the correct steel channel size is critical for the structural integrity and safety of any project. By understanding the varieties of steel channels available—from small to large sizes, their load capacities, and specific application needs—construction professionals can ensure they make informed decisions that enhance both the performance and longevity of their structures. In the continually evolving world of construction material technology, staying updated with channel sizes and specifications remains essential for achieving optimal results in engineering and building design.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

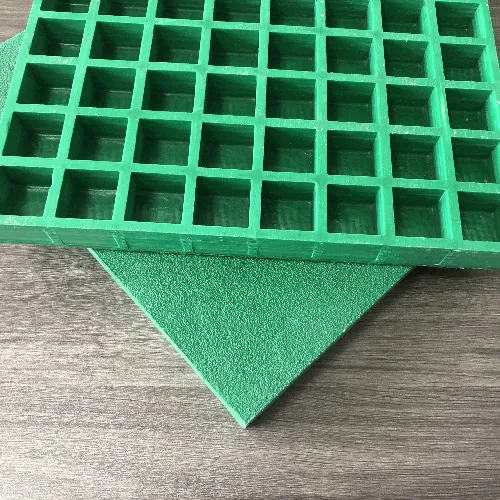

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025