loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Feb . 19, 2025 08:19

Back to list

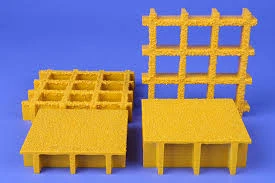

grp mini mesh grating

Navigating the world of industrial flooring solutions can be a challenging task, yet it is crucial for ensuring safety, efficiency, and longevity in various environments. Among the myriad of options available, moulded fibreglass grating consistently stands out due to its exceptional properties and versatile applications. Drawing from extensive experience in material analysis and industrial applications, this exploration into moulded fibreglass grating aims to underscore its unparalleled advantages while establishing its credibility as a premier choice for industry professionals.

Beyond performance metrics, the eco-friendly attributes of moulded fibreglass grating cannot be overlooked. With a growing imperative towards sustainable practices, the recyclable nature of fibreglass composites aligns well with green initiatives, thereby supporting organizations in meeting environmental goals without sacrificing performance or safety. From a design perspective, the customization options available with moulded fibreglass grating add another layer of appeal. Different panel thicknesses, mesh sizes, and colors allow for tailored solutions that meet specific functional and aesthetic requirements. This adaptability ensures seamless integration into existing infrastructures, offering both form and function in one robust package. The adoption of moulded fibreglass grating delivers a competitive edge, marrying durability with innovative design to meet the high demands of modern industries. Whether it's the rigorous environments of an offshore platform or the precision-driven floors of a production facility, the choice of the right grating material translates to a foundational investment in safety and performance. In conclusion, moulded fibreglass grating emerges not just as an alternative to traditional materials but as an advanced solution that addresses contemporary industrial challenges with precision. Its proven track record, compliance with standards, and inherent flexibility underscore its reputation as a trusted, authoritative choice. For stakeholders seeking to champion industry-leading safety and efficiency, choosing moulded fibreglass grating is an informed and strategic decision.

Beyond performance metrics, the eco-friendly attributes of moulded fibreglass grating cannot be overlooked. With a growing imperative towards sustainable practices, the recyclable nature of fibreglass composites aligns well with green initiatives, thereby supporting organizations in meeting environmental goals without sacrificing performance or safety. From a design perspective, the customization options available with moulded fibreglass grating add another layer of appeal. Different panel thicknesses, mesh sizes, and colors allow for tailored solutions that meet specific functional and aesthetic requirements. This adaptability ensures seamless integration into existing infrastructures, offering both form and function in one robust package. The adoption of moulded fibreglass grating delivers a competitive edge, marrying durability with innovative design to meet the high demands of modern industries. Whether it's the rigorous environments of an offshore platform or the precision-driven floors of a production facility, the choice of the right grating material translates to a foundational investment in safety and performance. In conclusion, moulded fibreglass grating emerges not just as an alternative to traditional materials but as an advanced solution that addresses contemporary industrial challenges with precision. Its proven track record, compliance with standards, and inherent flexibility underscore its reputation as a trusted, authoritative choice. For stakeholders seeking to champion industry-leading safety and efficiency, choosing moulded fibreglass grating is an informed and strategic decision.

Share

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025