loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

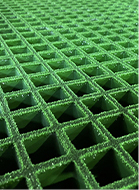

Innovative Solutions for FRP Molded Gratings in Industrial Applications

The Benefits of FRP Moulded Gratings A Comprehensive Overview

FRP (Fiberglass Reinforced Plastic) moulded gratings have emerged as an increasingly popular choice in various industries for several reasons. These advanced materials combine strength, durability, and lightweight properties, making them ideal for a range of applications, from construction to chemical processing. This article explores the key benefits, applications, and considerations of using FRP moulded gratings.

What are FRP Moulded Gratings?

FRP moulded gratings are constructed from glass fiber reinforced plastic, a composite material that enhances the strength and performance of the gratings. The production process typically involves combining glass fibers with a thermosetting resin, which is then moulded into grating panels of various sizes and configurations. This process not only provides a strong and lightweight structure but also allows for customized designs to suit specific needs.

Benefits of FRP Moulded Gratings

1. Corrosion Resistance One of the most significant advantages of FRP gratings is their excellent resistance to corrosion. Unlike traditional materials such as steel, FRP does not suffer from rust or degradation when exposed to harsh chemicals, moisture, or environmental conditions. This makes them highly suitable for use in chemical plants, wastewater treatment facilities, and marine environments.

2. Lightweight and Easy to Install FRP moulded gratings are significantly lighter than steel or aluminum gratings. This characteristic not only reduces transport costs but also makes handling and installation much more manageable. As a result, there is often a decrease in labor costs associated with installation, contributing to overall project efficiency.

3. High Load-Bearing Capacity Despite being lightweight, FRP gratings possess a remarkable load-bearing capacity. They can handle substantial weight without compromising structural integrity, making them suitable for industrial applications where heavy loads are common.

4. Safety Features FRP moulded gratings offer superior slip resistance, which enhances safety in workplaces, especially in wet or oily conditions. Many variations come with a textured surface, further reducing the risk of slips and falls.

5. Reduced Maintenance The durability of FRP materials translates to lower maintenance requirements over time. Unlike metal gratings that may require regular inspections and treatments to prevent corrosion, FRP gratings need minimal upkeep, which can save time and money in the long run.

frp moulded gratings

6. UV Resistance FRP is resistant to ultraviolet radiation, which helps prevent degradation from prolonged sun exposure. This feature is particularly beneficial for outdoor installations, where conventional materials may deteriorate over time.

Applications of FRP Moulded Gratings

FRP moulded gratings are versatile and can be used in various applications, including

- Industrial Flooring In factories and manufacturing plants, FRP gratings provide a durable and safe flooring option.

- Walkways and Platforms Their lightweight and corrosion-resistant nature makes them ideal for walkways above water or in chemically aggressive environments.

- Drains and Trenches FRP gratings are often used in drainage systems due to their ability to withstand harsh conditions.

- Water Treatment Facilities Their resistance to corrosion makes FRP gratings suitable for use in water treatment plants.

Conclusion

FRP moulded gratings are a modern solution that combines durability, safety, and low maintenance. With their impressive range of benefits and diverse applications, they offer outstanding performance in harsh environments where traditional materials might fail. As industries continue to evolve and prioritize safety and efficiency, the demand for FRP moulded gratings is likely to grow, making them a key component in future construction and engineering projects.

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025

-

The Strength and Durability of FRP GratingNewsMay.21,2025

-

The Importance of Water Treatment Systems for Clean and Safe WaterNewsMay.21,2025

-

The Advantages of FRP Rebar for Construction ProjectsNewsMay.21,2025

-

Say Goodbye to Hard Water with a Reliable Water SoftenerNewsMay.21,2025

-

Maximize Your Water Storage with a Sectional Water TankNewsMay.21,2025

-

The Power of Filter VesselsNewsMay.19,2025